Preparation method for sputtering titanium ring

A titanium ring and sputtering technology, which is applied in the field of titanium metal product processing, can solve the problems of investing a lot of manpower and energy, inconsistent lines, cumbersome processes, etc., and achieve the effects of improving product quality, improving work efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Take 9kg of 99.995% titanium ingot, forge it into a "170×60mm" billet, roll it in one direction to a thickness of 6mm, level it after annealing at 960°C / 1h, and cut it into "900×55mm" Long slats, CNC milled to 893×50.5×3.2mm, flatness 0.2mm, thickness difference 0.13mm, surface roughness Ra=1.1μm.

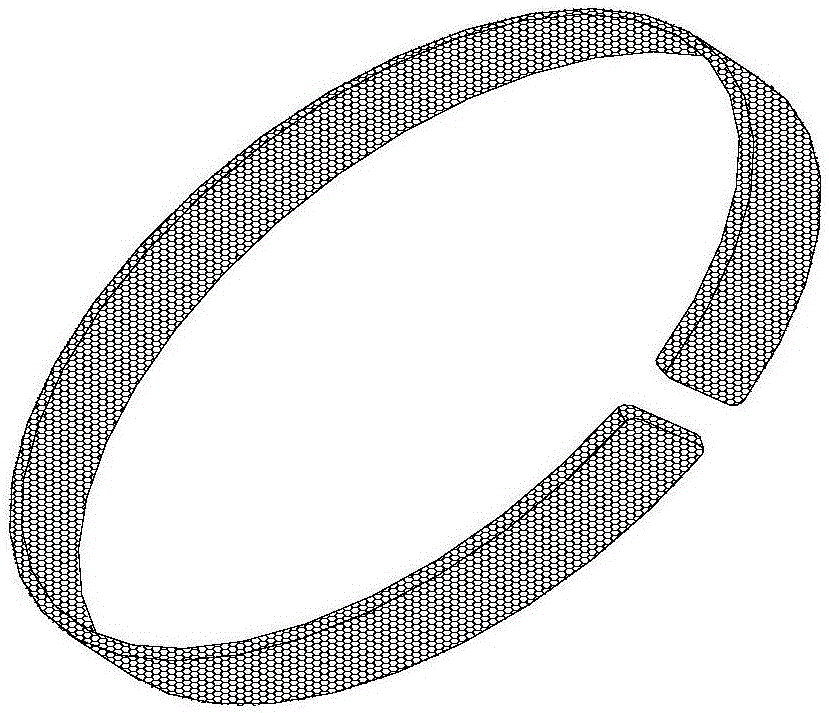

[0027] Choose a laser with a pulse width of 50ns, an average power of 60w, a pulse frequency of 20kHz, and an engraving line speed of 1500mm / s to engrave diamond-shaped lines on the long titanium slabs. The thickness of each layer is controlled to 0.05mm, and the duration is about 5h. Roll round, roundness 0.8mm, use 20% nitric acid, 5% hydrofluoric acid mixed acid to clean the engraved titanium ring for 4 minutes, then rinse with water, dehydrate and dry with absolute ethanol, the surface of the titanium ring is clean and free of dirt, The surface presents a uniform and smooth Ti metallic color.

Embodiment 2

[0029] Take 8.5kg of 99.999% titanium ingot, forge it into a "170×60mm" billet, roll it in one direction to a thickness of 5.6mm, level it after annealing at 885°C / 2h, and cut it into a "900×55mm" "Long slats, CNC milling to 893×50.5×3.2mm, flatness 0.16mm, thickness difference 0.1mm, surface roughness Ra=0.8μm.

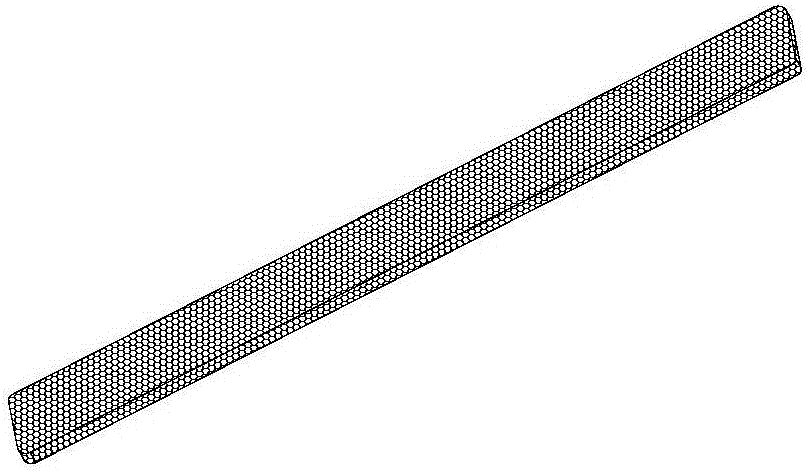

[0030] Choose a laser with a pulse width of 10ns, an average power of 150w, a pulse frequency of 100kHz, and an engraving line speed of 3000mm / s to engrave regular hexagonal patterns on titanium long slabs. The thickness of each layer is controlled at 0.1mm, and the duration is about 7h. The roundness of the circular machine is 0.8mm. The engraved titanium ring is cleaned with a mixed acid of 30% nitric acid and 4% hydrofluoric acid for 6 minutes, then rinsed with clean water, dehydrated with absolute ethanol and dried. The surface of the titanium ring is clean and free of dirt. Dirt, engrave a regular hexagonal column with a side length of 1mm and a depth of 0.5mm. ...

Embodiment 3

[0032] Receive about 8.8kg of 99.95% titanium ingot, forge it into a "170×60mm" billet, roll it in one direction to a thickness of 5.5mm, level it after annealing at 1200℃ / 2h, and cut it into a "900× 55mm” long slats, CNC milling to 893×50.5×3.2mm, flatness 0.18mm, thickness difference 0.12mm, surface roughness Ra=0.7μm.

[0033] Choose a laser with a pulse width of 90ns, an average power of 120w, a pulse frequency of 80kHz, and an engraving line speed of 1500mm / s to engrave circular lines on the long titanium slabs. The thickness of each layer is controlled to 0.15mm, and the duration is about 6h. Machine-rolled round, roundness 1mm, use 20% nitric acid, 7% hydrofluoric mixed acid solution to clean the engraved titanium ring for 4 minutes, then rinse with clean water, dehydrate and dry with absolute ethanol, the surface of the titanium ring is clean and free of dirt, and the engraved The outer diameter is 0.7mm, and the depth is 0.4mm cylindrical.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flatness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Average power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com