Wasabi toothpaste and production process thereof

A production process, the technology of wasabi, applied in the field of daily chemicals, can solve the problems of unfavorable industrialized production, resource waste environment, easy to wear tooth enamel, etc., prevent graininess and unevenness, simple drying process, and prevent oral ulcers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

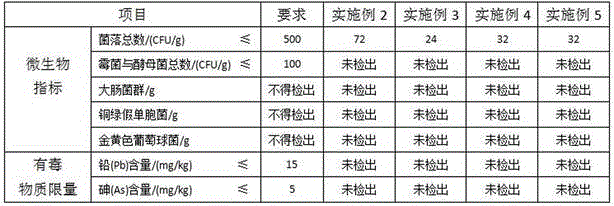

Examples

Embodiment 1

[0035] A kind of wasabi toothpaste, comprises the component of following mass parts:

[0036] Wasabi petiole superfine powder 10-15 parts

[0037] Wetting agent 15-20 parts

[0038] Moisturizer 5-8 parts

[0039] Friction agent 38—45 parts

[0040] Foaming agent 3-5 parts

[0041] Adhesive 0.8—1 part

[0042] Thickener 0.4—0.5 part

[0043] Sweetener 0.3—0.5 parts

[0044] Preservatives 0.2—0.3 parts

[0045] Emulsifier 0.2—0.3 part

[0046] 10-15 parts of deionized water.

[0047] Wherein, the friction agent is a mixture of calcium hydrogen phosphate dihydrate and hydrated silica, the mass ratio of calcium hydrogen phosphate dihydrate and hydrated silica is 8-12:1, the wetting agent is glycerin, and the moisturizing agent Sorbitol, the foaming agent is sodium lauryl sulfate, the binder is sodium carboxymethylcellulose, the thickener is xanthan gum, the sweetener is saccharin, and the preservative It is methyl paraben, and the emulsifier is tetrasodium pyrophosphate....

Embodiment 2

[0056] A kind of wasabi toothpaste, comprises the component of following mass parts:

[0057] 10 parts of superfine powder of wasabi petiole, 20 parts of wetting agent, 5 parts of humectant, 45 parts of friction agent, 5 parts of foaming agent, 1 part of adhesive, 0.5 part of thickener, 0.3 part of sweetener, 0.2 part of preservative Parts, 0.2 parts of emulsifier, 12.8 parts of deionized water. Wherein, the friction agent is a mixture of calcium hydrogen phosphate dihydrate and hydrated silica, and the mass ratio of calcium hydrogen phosphate dihydrate to hydrated silica is 8:1

[0058] Present embodiment also provides a kind of production technology of wasabi toothpaste, comprises the steps:

[0059] A, the preparation of superfine powder, the specific process is: wash the fresh wasabi petiole, drain, dry at 55° C., and pass through a superfine pulverizer to obtain wasabi petiole superfine powder with a particle size of 1000 mesh.

[0060] B. Glue making, the specific proc...

Embodiment 3

[0066] A kind of wasabi toothpaste, comprises the component of following mass parts:

[0067] 15 parts of superfine powder of wasabi petiole, 20 parts of wetting agent, 8 parts of moisturizing agent, 38 parts of friction agent, 3 parts of foaming agent, 0.8 part of adhesive, 0.5 part of thickener, 0.5 part of sweetener, 0.3 part of preservative parts, 0.3 parts of emulsifier, 13.6 parts of deionized water. Wherein, the friction agent is a mixture of calcium hydrogen phosphate dihydrate and hydrated silica, and the mass ratio of calcium hydrogen phosphate dihydrate to hydrated silica is 12:1.

[0068] Present embodiment also provides a kind of production technology of wasabi toothpaste, comprises the steps:

[0069] A, the preparation of superfine powder, the specific process is: wash the fresh wasabi petiole, drain, dry at 60° C., and pass through a superfine pulverizer to obtain wasabi petiole superfine powder with a particle size of 800 mesh.

[0070] B. Glue making, the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com