OLED displayer and manufacturing method thereof

A production method and display technology, which are applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of limiting the wide application of OLED displays, reducing luminous efficiency, lifespan, and denaturation, and improving UV resistance and light resistance. The effect of aging performance, improving mechanical properties and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

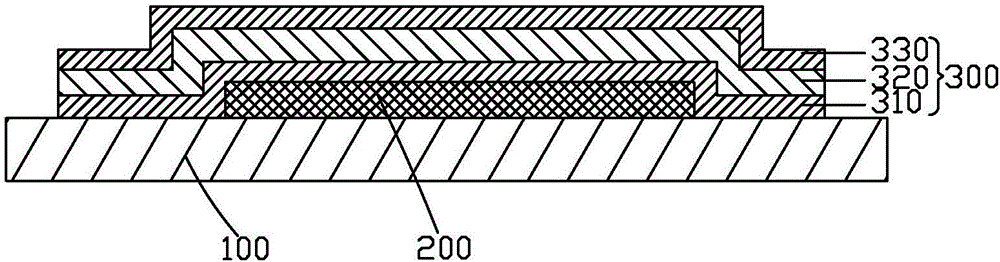

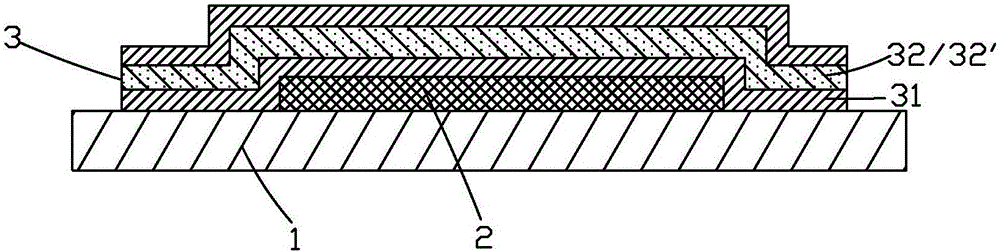

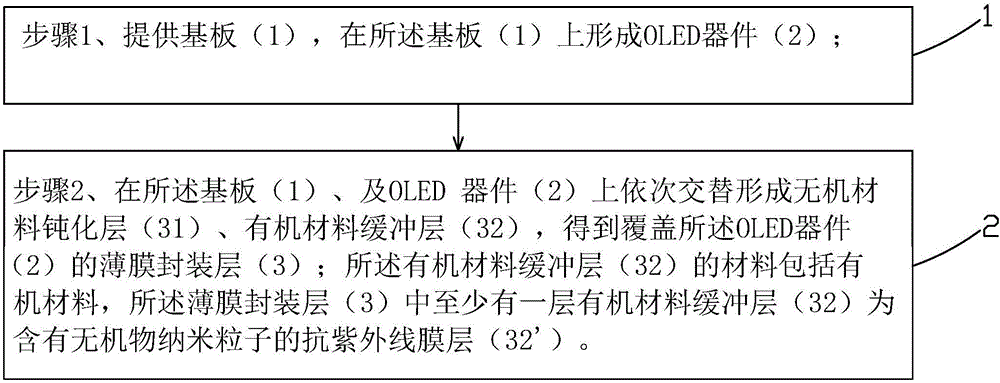

[0036] see figure 2 , the present invention provides an OLED display, comprising a substrate 1, an OLED device 2 disposed on the substrate 1, and a thin film encapsulation layer 3 disposed on the substrate 1 and the OLED device 2 and covering the OLED device 2;

[0037] The thin film encapsulation layer 3 includes at least two passivation layers 31 of inorganic materials and at least one buffer layer 32 of organic materials; in the thin film encapsulation layer 3, passivation layers 31 of inorganic materials and buffer layers 32 of organic materials are alternately stacked , and the inorganic material passivation layer 31 has one more layer than the organic material buffer layer 32, so that the film layers on both sides of the outermost sides...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com