High-pressure fine filtering manifold and filtering method thereof

A fine filtration, high-pressure technology, applied in earthwork drilling, wellbore/well components, flushing wellbore, etc., can solve the problem of poor capture effect, affecting the effect of mechanical impurity treatment and throttling control in drilling and grinding fluid, manual Eliminate problems such as erosion and damage of pipe fittings such as flat valves, and achieve the effect of increasing filtration capacity, good filtration effect, and improved filtration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

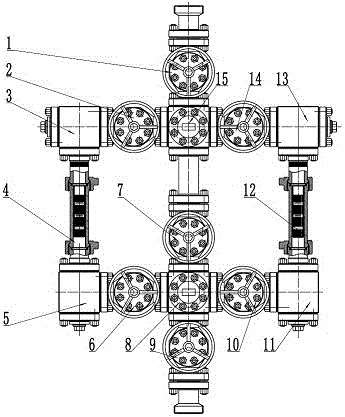

[0027] This embodiment provides a high-pressure fine filter manifold, including a five-way connection 15 as the inlet of the manifold, a five-way connection 2 8 as the outlet of the manifold, a five-way connection 15 and a five-way connection 8 They are respectively connected by three channels, one of which is a straight-line channel, and the other two channels are connected in series with high-pressure filter joints.

[0028] One of the mouths of the pipeline five-way one 15 is installed with a manual flat gate valve one 1 as a manifold inlet; one of the mouths of the five pipeline five-way two 8 is installed with a manual flat gate valve two 9 as a manifold outlet; Two nozzles of the five-way connection 15 are respectively connected to a pipeline tee through a pipeline, and the pipeline tee is connected to another pipeline tee through a high-pressure filter joint, and then connected to the pipeline five-way 2 8 One of the nozzles is connected through a pipeline; one of the n...

Embodiment 2

[0031] combine figure 1 As shown, in this embodiment, the high-pressure filter nipple includes a high-pressure filter nipple 1 and a high-pressure filter nipple 2 12, and the above three channels are specifically:

[0032] The first passage consists of a nozzle of pipeline five-way one 15, manual flat gate valve three 2, pipeline three-way one 3, high-pressure filter nipple one 4, pipeline three-way two 5, manual flat gate valve four 6, pipe One of the nozzles of Luwutong No. 2 and 8 is connected in sequence;

[0033] The second channel is composed of a nozzle of the five-way connection 15 of the pipeline, a manual flat gate valve 77, and a nozzle of the five-way connection 28 of the pipeline in sequence;

[0034] The third passage consists of a nozzle of pipeline five-way one 15, manual flat gate valve five 14, pipeline three-way three 13, high-pressure filter nipple two 12, pipeline three-way four 11, manual flat gate valve six 10, pipe A nozzle of Luwutong 2 8 is connecte...

Embodiment 3

[0036] High-pressure filter sub-section 1 4 and high-pressure filter sub-section 2 12 are equipped with erosion-resistant carbide filter cartridges of different slit sizes processed by wire cutting technology. According to the displacement and the size of mechanical impurities in the drilling and grinding fluid, install an erosion-resistant carbide filter cartridge with a suitable slot size in the high-pressure filter nipple.

[0037]This embodiment also provides a set of filter manifolds with specific sizes in combination with the high-pressure filter nipple. In this embodiment, the manifold is 2100mm long, 1450mm wide, 520mm high, and the pipeline diameter is 65mm (2-9 / 16" ), the pressure is 35MPa (5000psi); the high-pressure filter sub-section 1 4 and the high-pressure filter sub-section 2 12 are made of 35CrMo material, and the hardness reaches HBW197-235 after heat treatment; The filter cartridge is made of erosion-resistant cemented carbide tungsten carbide YG8 material,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com