Preparation method of polyimide fiber paper

A technology of polyimide fiber and polyimide, which is applied in the field of preparation of polyimide fiber paper, can solve the problems of low strength of wet paper web, difficult traction of paper machine, poor performance of paper sheets, etc., and achieves Good practical application value and prospect, increase surface energy, and reduce the effect of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

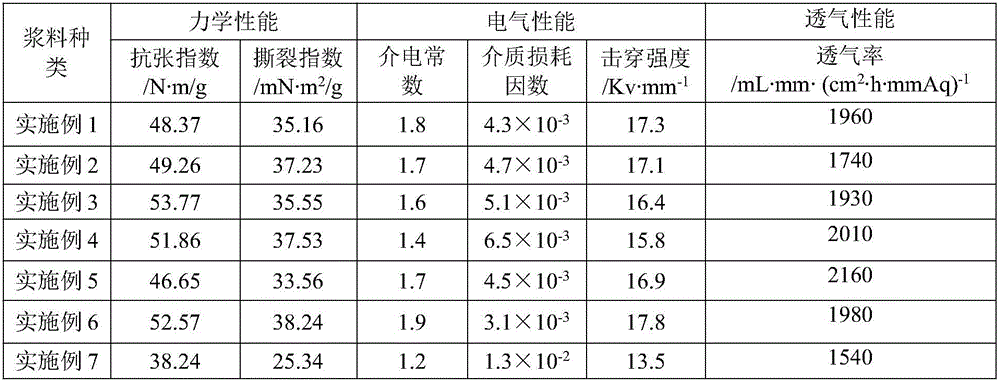

Examples

Embodiment 1

[0040] Use 80g of dry polyimide 3mm chopped fibers and 20g of dry meta-aramid precipitated fibers as slurry, polyimide chopped fibers are treated with 10% NaOH at 30°C for 1 hour, and then washed with distilled water Fiber to neutral, the meta-aramid precipitated fiber is thawed and mixed with polyimide chopped fiber, pre-soaked for 1.5h under the condition of mechanical stirring, the amount of dispersant M is 2.605% of the dry pulp mass, Dissolve in distilled water to obtain the dispersant M solution, then mix with the slurry, soak for 0.5h under mechanical stirring, and then take the quantitative amount of 50g / m according to the wet papermaking process 2 Polyimide fiber base paper, the base paper is hot-pressed under the conditions of 10 MPa and 240° C. for 10 minutes in a hot press to obtain polyimide fiber paper.

[0041]Wherein, in the present embodiment, the dispersant M, in parts by weight, consists of 0.6 part of polyvinyl alcohol, 1.0 part of antistatic agent TM (meth...

Embodiment 2

[0044] Use 60g of dry polyimide 3mm chopped fibers and 40g of dry para-aramid fibrids as slurry, polyimide chopped fibers are treated with 5% KOH at 60°C for 1 hour, and then washed with distilled water Fiber to neutral, the p-aramid precipitated fiber is thawed and mixed with polyimide chopped fiber, pre-soaked for 1h under mechanical stirring, the amount of dispersant M is 3.006% of the dry pulp mass, with Dissolve in distilled water to obtain dispersant M solution, then mix with the slurry and soak for 1h under mechanical stirring, then take the quantitative amount of 40g / m according to the wet papermaking process 2 Polyimide fiber base paper, the base paper is hot-pressed under the conditions of 5Mpa and 280° C. for 15 minutes in a hot press to obtain polyimide fiber paper.

[0045] Among them, the dispersant M in this embodiment consists of 0.75 parts by weight of polyacrylamide, 0.9 parts of antistatic agent SN (octadecyldimethylhydroxyethyl quaternary ammonium nitrate),...

Embodiment 3

[0048] Using 90g of dry polyimide 6mm chopped fiber and 10g of dry polyester fiber as slurry, the polyimide chopped fiber was treated with 10.8% HCl at 90°C for 3 hours, and then washed with distilled water until neutral , mixed with polyester fiber and polyimide chopped fiber, pre-soaked for 2h under the condition of mechanical stirring, the amount of dispersant M was 2.808% of the mass of dry pulp, dissolved in distilled water to obtain dispersant M solution, and then mixed with pulp The materials are mixed and soaked for 1h under the condition of mechanical stirring, and then according to the wet papermaking process, the quantitative is 50g / m 2 Polyimide fiber base paper, the base paper is hot-pressed under the condition of 5Mpa and 300° C. for 5 minutes in a hot press to obtain polyimide fiber paper.

[0049] Among them, the dispersant M in the present embodiment, in parts by weight, consists of 0.65 parts of polyethylene oxide, 0.35 parts of antistatic agent P (ammonium a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com