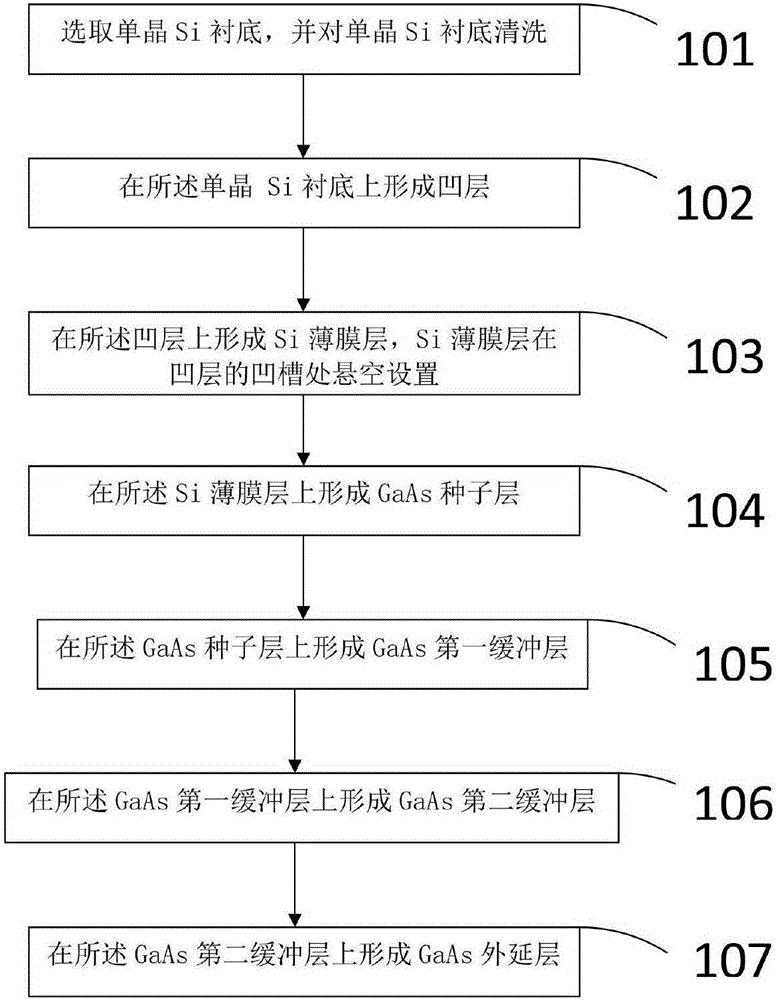

GaAs/Si epitaxial material preparation method

An epitaxial material and seed layer technology, which is used in the growth of polycrystalline materials, chemical instruments and methods, semiconductor/solid-state device manufacturing, etc. dislocation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

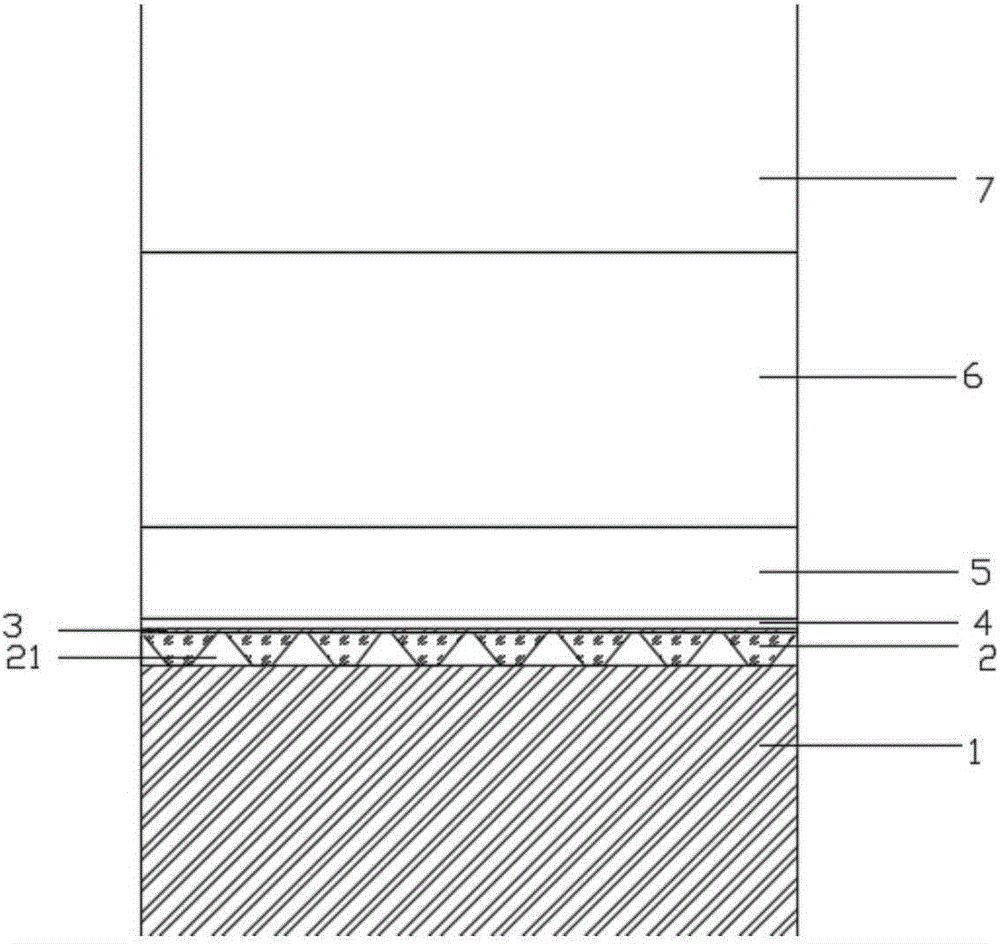

[0035] Step 101: Select a single crystal Si substrate 1 and clean the single crystal Si substrate 1 .

[0036] The crystal plane of the single crystal Si substrate 1 is the (100) crystal plane, which is an intrinsic type n-type silicon wafer with a thickness of 400 μm, and the growth of silicon is biased to the (011) crystal plane by 6° to form diatomic steps and suppress Reverse domain formation.

[0037] Step 102 : forming a concave layer 2 on the single crystal Si substrate 1 .

[0038] The formation process of the concave layer 2 is as follows: firstly, a SiO2 thin layer is formed on the surface of the single crystal Si substrate 1 by thermal oxidation, and ion implantation is performed through the SiO2 thin layer to prevent the single crystal Si substrate 1 from being polluted during the ion implantation process , high-energy ion implantation into Si, and then use HF to remove the SiO2 thin layer, and then selectively wet-etch the single-crystal Si substrate 1 after impl...

Embodiment 2

[0050] Step 101: Select a single crystal Si substrate 1 and clean the single crystal Si substrate 1 .

[0051] The crystal plane of the single crystal Si substrate 1 is the (100) crystal plane, which is an intrinsic type n-type silicon wafer with a thickness of 400 μm, and the growth of silicon is biased towards the (011) crystal plane by 4°.

[0052] Step 102 : forming a concave layer 2 on the single crystal Si substrate 1 .

[0053] The formation process of the concave layer 2 is as follows: firstly, Si ions are implanted into the single crystal Si substrate 1 with high-energy ions, and then the single crystal Si substrate implanted with Si ions is selectively dry etched to form the concave layers arranged in an array. The groove 21 constitutes the concave layer 2 and has a thickness of 90 nm.

[0054] Step 103 : forming a Si thin film layer 3 on the concave layer 2 , and the Si thin film layer 3 is suspended in the groove 21 of the concave layer 2 .

[0055] The Si thin f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com