Zinc-nickel alloy plating liquid and application thereof

A zinc-nickel alloy and liquid-passing technology, which is applied in the field of zinc-nickel alloy liquid-passing, can solve problems such as unstable electroplating effect and poor corrosion resistance of zinc-nickel alloy, and achieve easy expansion of production, excellent physical properties, and electroplating The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

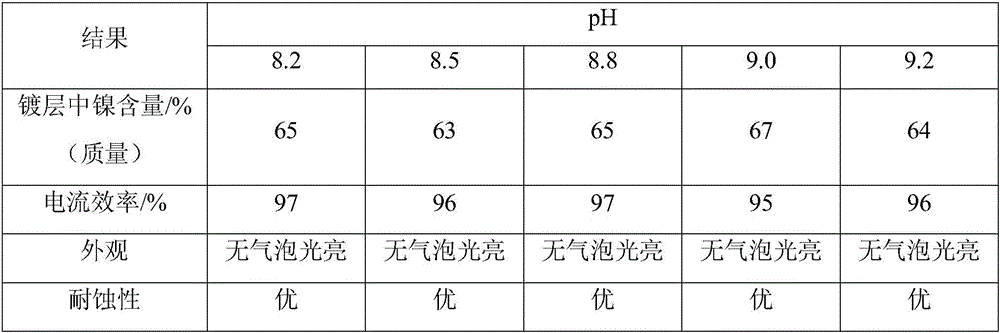

[0022] Example 1: Effect of pH on coating composition and current efficiency.

[0023] The composition of the electroplating solution is as follows:

[0024] Zinc sulfate 0.08mol / L, nickel sulfamate 0.1mol / L, sodium hydroxide 0.03mol / L, ammonium chloride 0.02mol / L, boric acid 0.0025mol / L, β-naphthoic acid sodium 0.002mol / L, leucine Acid 0.0001mol / L, isoleucine 0.0001mol / L, brightener, complexing agent, pH8.8~9.2, solvent is water.

[0025] Plating method:

[0026] Put the cleaned copper piece into the palladium ferry, the current density is 0.1-0.3A / dm2, the temperature of the bath is 28°C, and the tank pressure is 4V.

[0027] Electroplating effect: It can be seen from Table 1 that the electroplating effect is between pH 8.2 and 9.2.

[0028] Table 1 Effect of pH on coating composition and current efficiency

[0029]

Embodiment 2

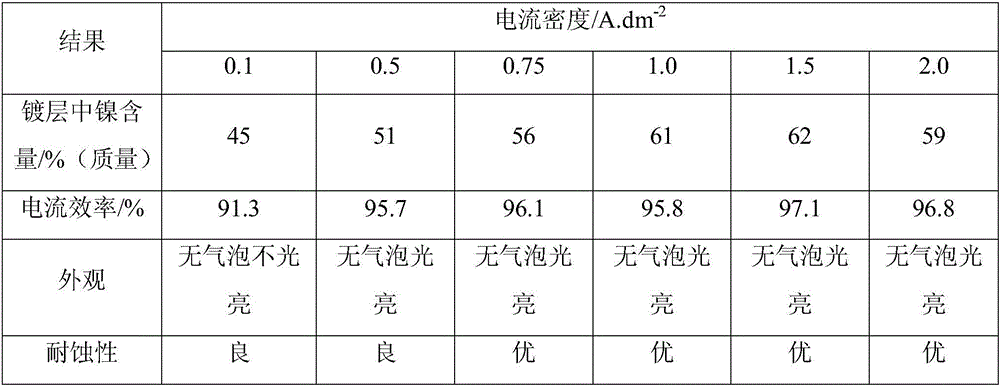

[0031] The composition of the electroplating solution is as follows:

[0032] Zinc sulfate 0.1mol / L, nickel sulfamate 0.2mol / L, sodium hydroxide 0.01mol / L, ammonium chloride 0.03mol / L, boric acid 0.003mol / L, β-naphthoic acid sodium 0.002mol / L, leucine Acid 0.0002mol / L, isoleucine 0.0003mol / L, brightener, complexing agent, pH8.8~9.2, solvent is water.

[0033] Electroplating method: Put the cleaned copper alloy into the palladium bath, the current density is 0.1-0.5.A / dm 2 , the bath temperature is 35°C, and the tank pressure is 4V.

[0034] Electroplating effect: It can be seen from Table 2 that the current density is the best when the current density is 0.5-1.0.

[0035] Table 2 Effect of current density on coating composition and current efficiency

[0036]

Embodiment 3

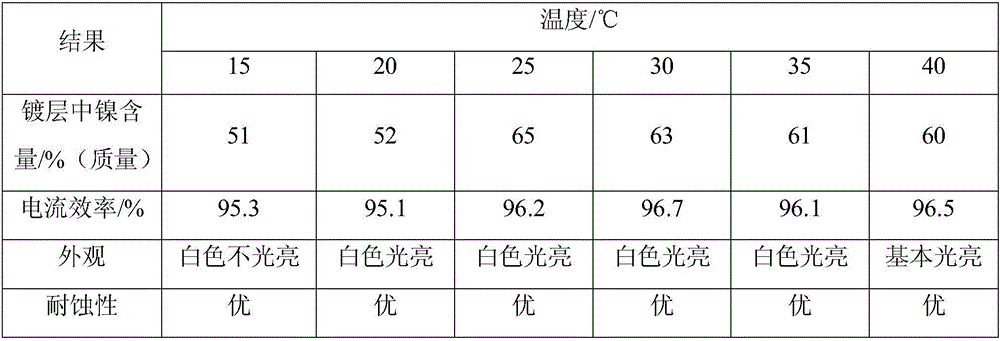

[0038] The composition of the electroplating solution is as follows:

[0039] Zinc sulfate 0.09mol / L, nickel sulfamate 0.15mol / L, sodium hydroxide 0.03mol / L, ammonium chloride 0.03mol / L, boric acid 0.0025mol / L, β-naphthoic acid sodium 0.0015mol / L, leucine Acid 0.0001mol / L, isoleucine 0.0001mol / L, brightener, complexing agent, pH8.8~9.2, solvent is water.

[0040] Plating method:

[0041] Put the cleaned copper alloy into the palladium ferry, the current density is 0.1-0.5.A / dm 2 , the bath temperature is 15-40°C, and the tank pressure is 4V.

[0042] Electroplating effect: test results are shown in Table 3

[0043] Table 2 Effect of temperature on coating composition and current efficiency

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com