Nickel-based molybdenum disulfide powder for laser cladding and preparing method and application method of nickel-based molybdenum disulfide powder

A molybdenum disulfide powder and molybdenum disulfide technology are applied in the field of powder materials, which can solve the problems of limited application scope and application value, long time required for pre-melting layer, unsuitable for industrialization, etc. Reduce the effect of vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

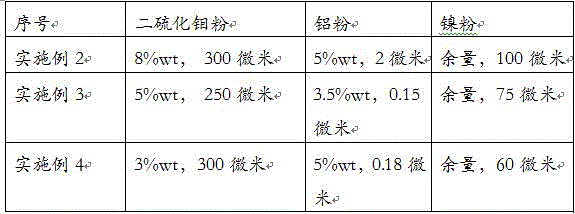

Examples

Embodiment 1

[0034] The nickel-based molybdenum disulfide powder for laser cladding includes the following components:

[0035] Molybdenum disulfide: 3%wt, particle size 200 microns;

[0036] Aluminum: 2%wt, particle size 0.1 micron;

[0037] The balance is nickel with a particle size of 50 microns.

[0038] Its preparation process includes the following steps:

[0039] (1) Add the molybdenum disulfide powder, aluminum powder, and nickel powder that have been confirmed in particle size to the ethanol solution, stir it into a paste, then add it to the mixed solution of 80% ethanol and 20% methanol, soak for 10-30min, Remove the dirt on the surface of molybdenum disulfide powder, aluminum powder and nickel powder;

[0040] (2) Select quantitative filter paper to filter separately, and place them in a drying oven at 120°C for drying treatment for 30-60 minutes to remove residual ethanol and methanol;

[0041] (3) Powder mixing, weigh molybdenum disulfide powder and aluminum powder accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com