A kind of preparation method of az91d alloy with ultra-fine grain solidification structure

A technology of solidification structure and ultra-fine grain, which is applied in the field of preparation of AZ91D alloy, can solve the problems of limited refinement effect, no essential improvement in distribution and shape, and difficulty in achieving an average grain size below 100 microns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

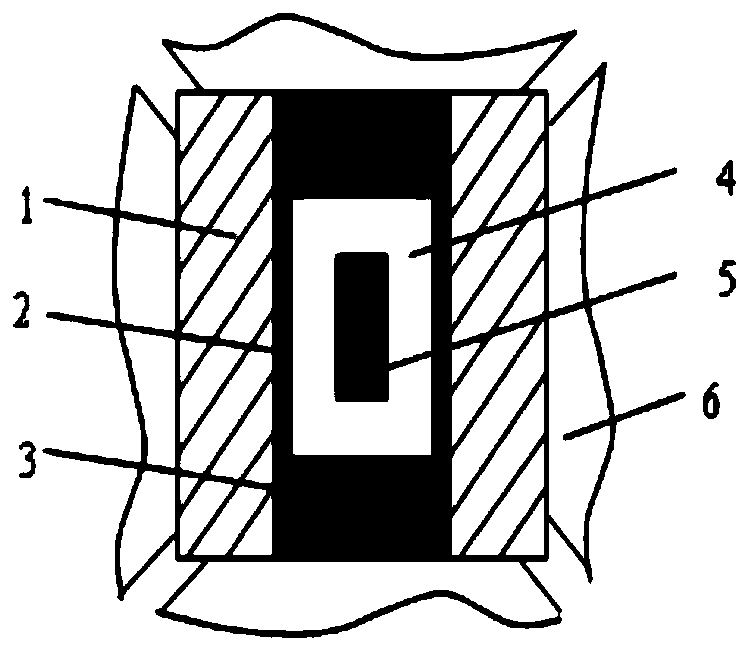

[0045] A preparation method of an AZ91D alloy with ultra-fine grain solidification structure, comprising the following steps:

[0046] (1) Pretreatment: AZ91D alloy ingots were taken for diffusion annealing, and wire-cut into samples with a diameter of 10 mm and a length of 6 mm;

[0047] (2) Sample high-pressure solidification treatment: place the sample in step (1) in a CS-1B high-pressure six-sided top press for high-pressure solidification treatment, set the solidification pressure and preset temperature, and raise the pressure to solidification The pressure is 2GPa, and at the same time, it is rapidly heated to the preset temperature of 950°C, and then kept at this temperature for heat preservation and pressure, and then the heating is stopped for 18 minutes, and it is naturally cooled to room temperature under the pressure-holding condition, and it is ready after the pressure is released.

Embodiment 2

[0049] A preparation method of an AZ91D alloy with ultra-fine grain solidification structure, comprising the following steps:

[0050] (1) Pretreatment: AZ91D alloy ingots were taken for diffusion annealing, and wire-cut into samples with a diameter of 12 mm and a length of 6 mm;

[0051] (2) Sample high-pressure solidification treatment: place the sample in step (1) in a CS-1B high-pressure six-sided top press for high-pressure solidification treatment, set the solidification pressure and preset temperature, and raise the pressure to solidification The pressure is 3GPa, and at the same time, it is rapidly heated to the preset temperature of 900°C, and then kept at this temperature for heat preservation and pressure, and then the heating is stopped for 20 minutes, and it is naturally cooled to room temperature under the pressure-holding condition, and the product is obtained after pressure relief.

Embodiment 3

[0053] A preparation method of an AZ91D alloy with ultra-fine grain solidification structure, comprising the following steps:

[0054] (1) Pretreatment: AZ91D alloy ingots were taken for diffusion annealing, and wire-cut into samples with a diameter of 6 mm and a length of 6 mm;

[0055](2) Sample high-pressure solidification treatment: place the sample in step (1) in a CS-1B high-pressure six-sided top press for high-pressure solidification treatment, set the solidification pressure and preset temperature, and raise the pressure to solidification The pressure is 4GPa, and at the same time, it is rapidly heated to the preset temperature of 850°C, and then kept at this temperature for heat preservation and pressure, and then the heating is stopped for 15 minutes, and it is naturally cooled to room temperature under the pressure-holding condition, and the product is obtained after pressure relief.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com