Thermoplastic elastomer film and its manufacturing method

A technology of elastomers and thermoplastic resins, applied in chemical instruments and methods, other household appliances, transportation and packaging, etc., can solve problems such as the influence of dispersed elastomer particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0072] A. A method of forming a dynamically vulcanized alloy film, the method comprising i) extruding a dynamically vulcanized alloy through at least one extruder die discharge orifice to form an extruded film having an extrusion die exit film temperature, the dynamically vulcanized alloy comprising at least one elastomer dispersed in continuous thermoplastic resin domains, ii) causing air to flow over the extruded film to reduce the temperature of the extruded film and create a film bloom line, and iii) moving the film through The film frost line to complete the film forming process; wherein the temperature of the extruded film is lowered at a cooling rate of less than 97° C. per second and the film frost line of the extruded film is within a distance of at least one extruder die row It is generated at the position where the material hole is larger than 135mm;

[0073] B. The method of embodiment A, wherein the cooling rate is less than 90°C per second, or less than 75°C per ...

Embodiment

[0097] DVA pellets for film extrusion were prepared in a twin-screw extruder. The DVA-forming components and amounts are identified in Table 1 below, respectively.

[0098] Table 1

[0099]

[0100] Pellets are prepared for film blowing by masticating the pellets in a screw extruder to bring the material to the desired extrusion temperature. Film thickness, air pressure values, and the die gap were varied to determine the effect of extrusion parameters on film bloom line and undercooling, as well as the shrinkage characteristics of the resulting aged films. The extrusion rate for the entire run was 71 kg / hr and for the values in Table 2 below, the film fold-flat bubble width was 610 mm, resulting from a bubble diameter of approximately 410 mm. This data is presented in Table 2 below.

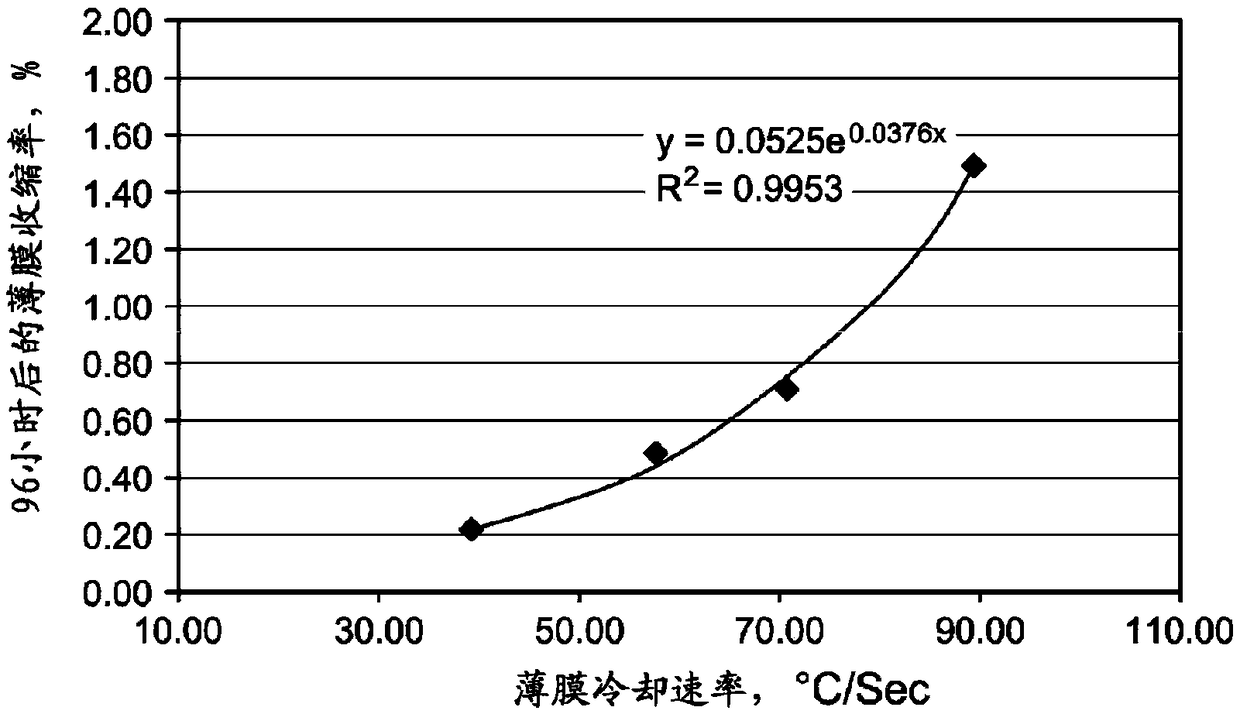

[0101] Reviewing the above data, for the two thickest gauges, 200 microns, the aged film shrinkage was the lowest. This may be due to the greater thickness of the thermoplastic domains ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com