Glass fiber reinforced polyurethane product with sandwich and production method thereof

A polyurethane and polyurethane layer technology, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problem of weak bonding between the glass fiber reinforced polyurethane layer and the sandwich layer, increased weight, surface delamination, etc. problem, to achieve the effect of reducing the risk of delamination or delamination, expanding the application range, and increasing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

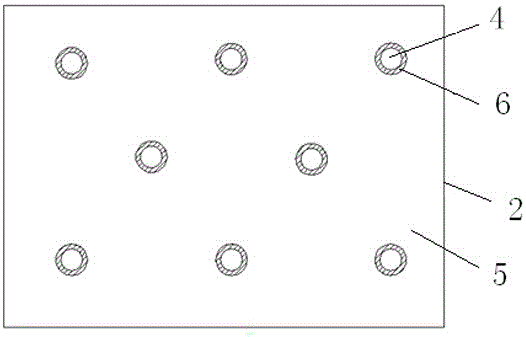

[0062] Such as figure 2 As shown, the depression 4 of the glass fiber reinforced polyurethane product with a sandwich is circular, the diameter of the bottom of the depression 4 is 50 mm, and the draft angle of the depression 4 is 30°. A total of 8 depressions 4 are designed, and their distribution is as follows figure 2 , evenly distributed circular depressions 4, the existence of depressions 4 on the product of this embodiment increases the bonding strength between the upper and lower layers of glass fiber reinforced polyurethane layers.

Embodiment 2

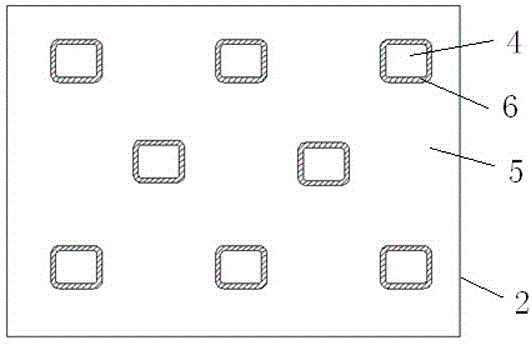

[0064] Such as image 3 As shown, the depression 4 of the glass fiber reinforced polyurethane product with a sandwich is a rectangle, the rectangle at the bottom of the depression 4 is 60mm long and 40mm wide, the four corners of the rectangle are rounded, the radius of the rounded corners is 5mm, and the draft of the depression 4 The angle is 30°, a total of 8 depressions are designed, and their distribution is as follows image 3 , evenly distributed rectangular depressions 4, the existence of the depressions 4 on the product of this embodiment increases the bonding strength between the upper and lower layers of glass fiber reinforced polyurethane layers 1 and 2.

Embodiment 3

[0066] Such as Figure 4 As shown, the depression 4 of the glass fiber reinforced polyurethane product with a sandwich is elongated. The depression 4 is 600mm long and 10mm wide. The two ends of the depression 4 are semicircles with a diameter of 10mm. The draft angle of the depression 4 is 30°. 9 depressions 4, distributed as Figure 4 In this embodiment, the glass fiber reinforced polyurethane product with a sandwich has an excellent reinforcement effect in the transverse direction, but the rigidity is reduced by the depression 4 in the longitudinal direction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com