Wall insulating mortar, its preparation method and grade A wall insulating material prepared with it

A technology of thermal insulation slurry and wall, which is applied in the field of wall thermal insulation slurry and non-combustible wall thermal insulation materials, which can solve problems such as melting and collapse of foam structure products, and achieve the effect of simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

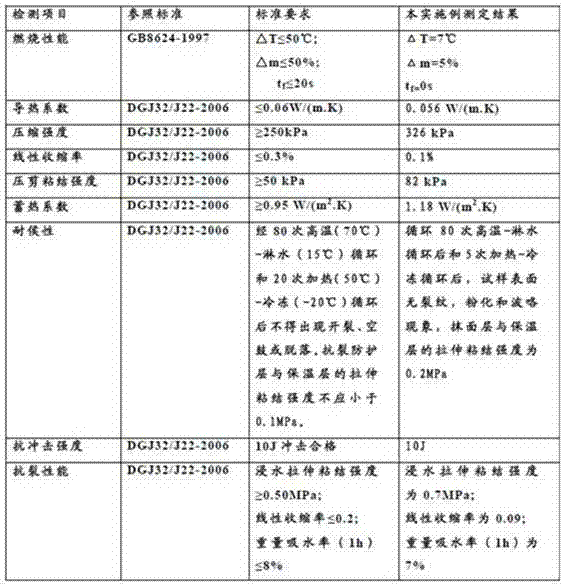

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below in conjunction with specific examples, but the invention is not limited to the following examples.

[0019] The wall thermal insulation slurry according to this embodiment is composed of the slurry main body and water, wherein the slurry main body is composed of the following components by weight: 500 kg of flame-retardant polystyrene particles; 200 kg of light calcium; 165 kg of gray calcium; Calcium 100kg; Hexabromocyclododecane 10kg; Latex powder 13kg; Methylcellulose 4kg; Ethylcellulose 5kg; Wood fiber 2kg; Glass fiber 1kg.

[0020] The preparation process of the above-mentioned wall insulation slurry is as follows:

[0021] (1) Preparation of flame-retardant polystyrene granules: 500 kg of polystyrene granules containing 10 kg of hexabromocyclododecane (commercially available) are heated and foamed by steam to form granules with a size of 3 to 5 mm;

[0022] (2) Stir the flame-retardant poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com