Recombinant clostridium for efficiently producing butanol, and construction method and application of recombinant clostridium

A technology for the production of butanol and its construction method, which is applied in the field of butanol-producing Clostridium and its construction, and can solve the problems of lack of directional transformation of target proteins and little research progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment includes the following steps:

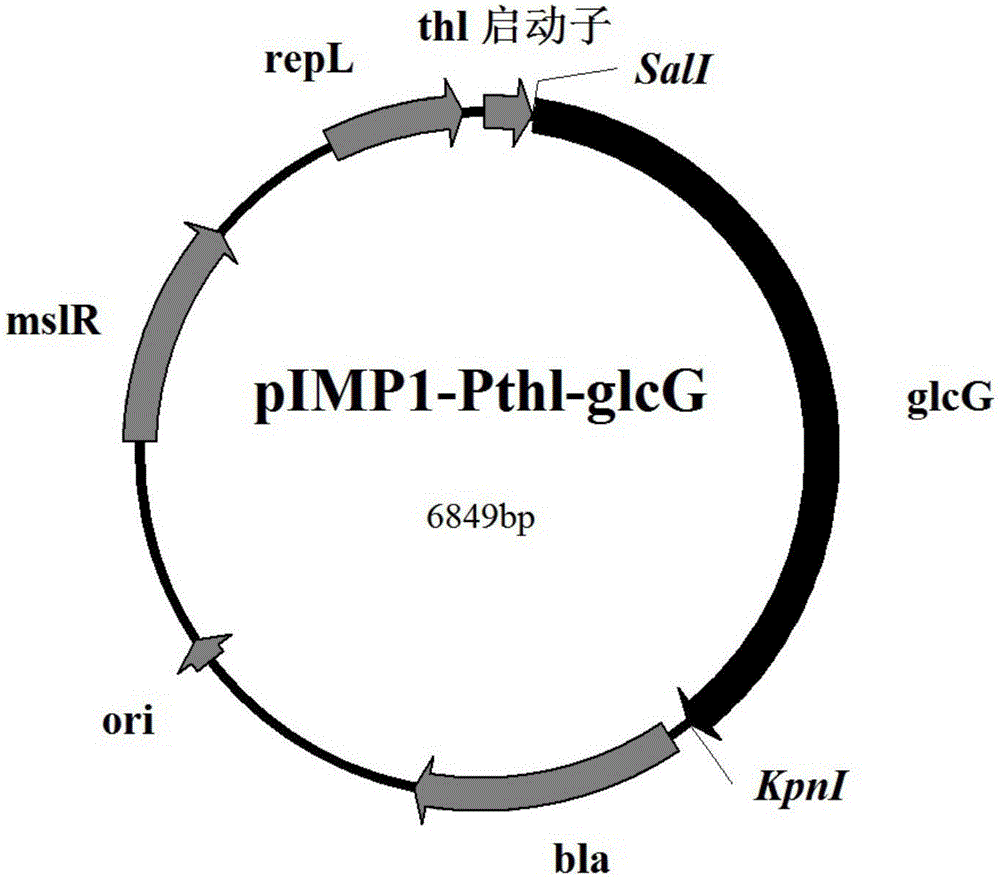

[0034] (1) Construction of pIMP1-Pthl plasmid

[0035] Genomic DNA of Clostridium acetobutylicum C. acetobutylicum ATCC 824 (purchased from the American Standard Biological Collection) was extracted using Sangon Biotech (Shanghai Shenggong) Ezup Column Bacterial Genomic DNA Extraction Kit (Product No.: B518255). Primer: Pthl-F: GACAC CTGCAG TTTTTAACAAAATATATTGA (the underlined part is the restriction site of Pst I) and Pthl-R: GACAC GTC GAC TTCTTTCATTCTAACTAACCTC (the underlined part is the Sal I restriction site) amplifies the promoter sequence of thiolase from genomic DNA (see SEQ ID NO.3 for the specific sequence), and uses the PCR-amplified thiolase promoter DNA with Pst I and Sal I were double-digested, and the pIMP1 plasmid [Mermelstein L.D., Welker N.E., Bennett G.N., Papoutsakis E.T. Expression of cloned homologous fermentative genes in Clostridium acetobutylicum ATCC824.Nature Biotechnology, 1992, 10 (2): 190...

Embodiment 2

[0041] Butanol is fermented by the recombinant bacterial strain, and the present embodiment comprises the following steps:

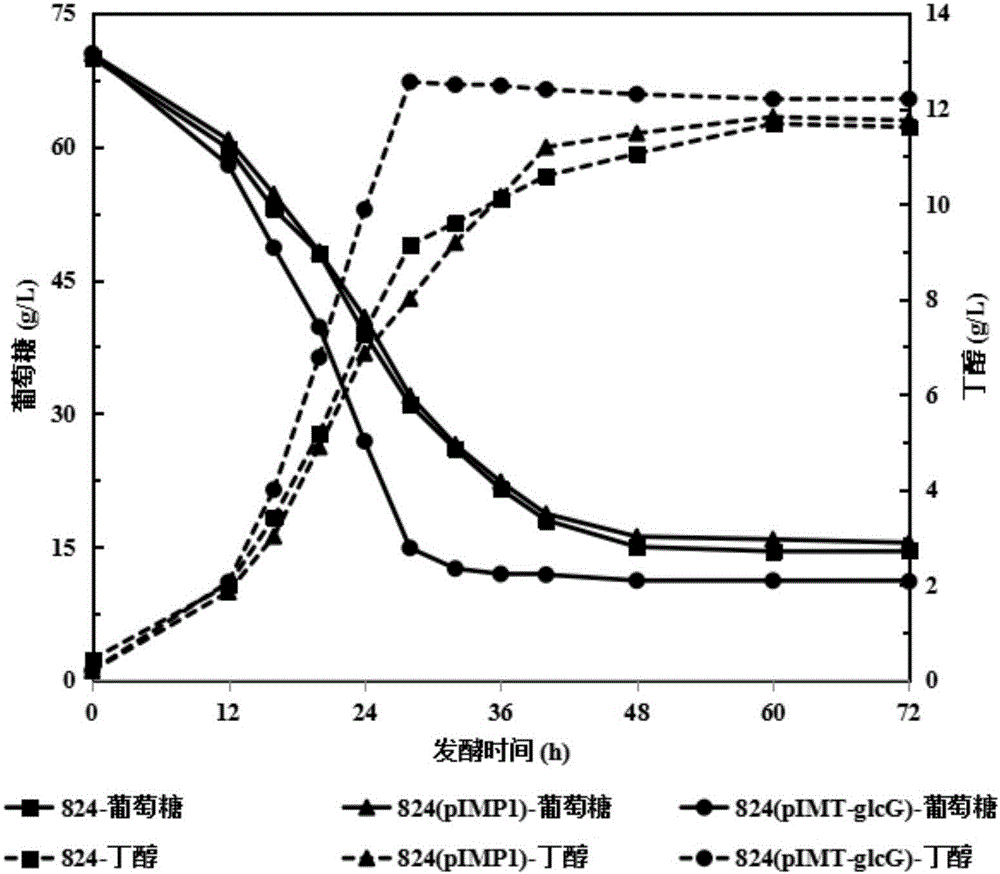

[0042] The recombinant bacterial strain Clostridium acetobutylicum ATCC 824 (pIMT-glcG) obtained in Example 1 and the control empty plasmid bacterial strain C.acetobutylicum ATCC 824 (pIMP1) and its departure wild-type bacterial strain C.acetobutylicum ATCC 824 were inoculated respectively into the activation medium (containing 10 μg / mL erythromycin resistance), placed in an anaerobic environment for static culture, the culture temperature was 37.5 ° C, and the activation culture was used for seed culture for 20 h; v / v) The inoculum amount was inoculated in the seed medium (containing 10 μg / mL erythromycin resistance), placed in an anaerobic environment for shake flask culture, the culture temperature was 37.5°C, the rotation speed was 150rpm, and the culture was 24-30h for Anaerobic fermentation culture: Biotec-3BG-4 fermenter (Shanghai Baoxing Bio-Equi...

Embodiment 3

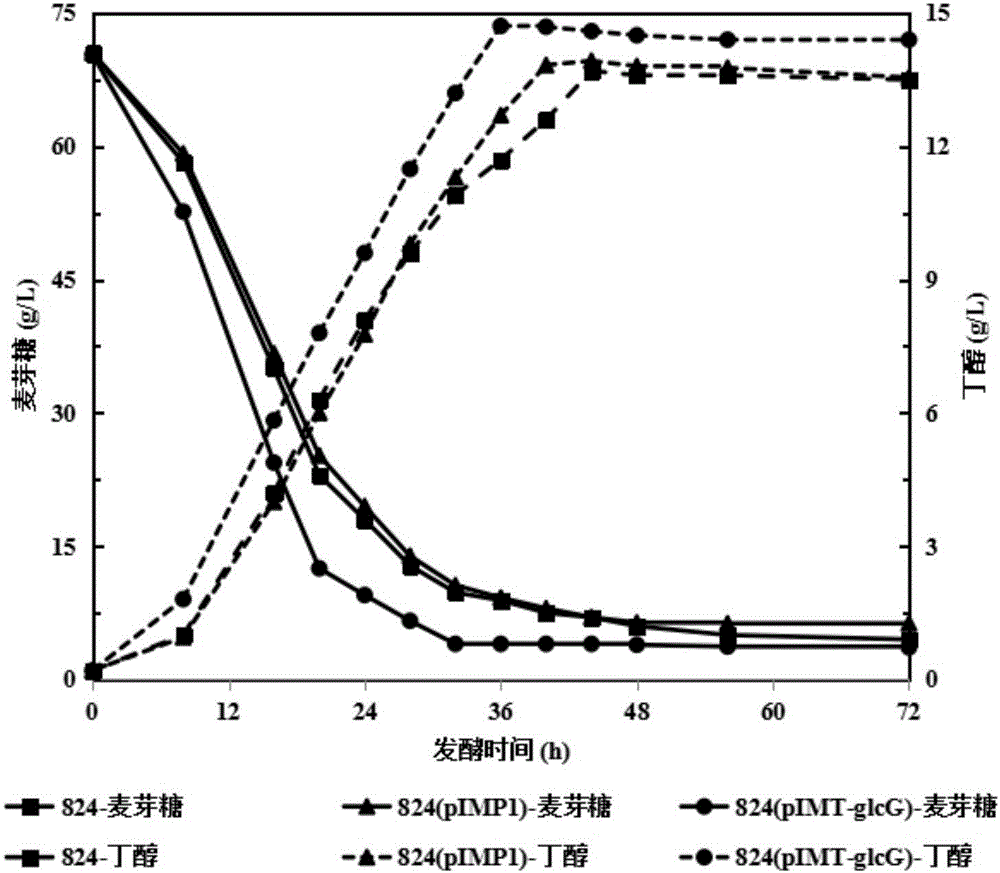

[0055] Butanol is fermented by the recombinant bacterial strain, and the present embodiment comprises the following steps:

[0056] The recombinant bacterial strain Clostridium acetobutylicum ATCC 824 (pIMT-glcG) obtained in Example 1 and the control empty plasmid bacterial strain C.acetobutylicum ATCC 824 (pIMP1) and its departure wild-type bacterial strain C.acetobutylicum ATCC 824 were inoculated respectively into the activation medium (containing 10 μg / mL erythromycin resistance), placed in an anaerobic environment for static culture, the culture temperature was 37.5 ° C, and the activation culture was used for seed culture for 20 h; v / v) The inoculum amount was inoculated in the seed medium (containing 10 μg / mL erythromycin resistance), placed in an anaerobic environment for shake flask culture, the culture temperature was 37.5°C, the rotation speed was 150rpm, and the culture was 24-30h for Anaerobic fermentation culture: Biotec-3BG-4 fermenter (Shanghai Baoxing Bio-Equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com