Self-glued asphalt adhesive material, preparation method of self-glued asphalt adhesive material, and self-glued asphalt waterproof coiled material

A technology of asphalt waterproof membrane and asphalt adhesive, which is applied in the direction of building insulation materials, building components, layered products, etc., and can solve the problem that waterproof membrane cannot be constructed or used, self-adhesive asphalt adhesive is easy to soften and overflow, and has poor heat resistance etc. to avoid fire risk, improve heat resistance, and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

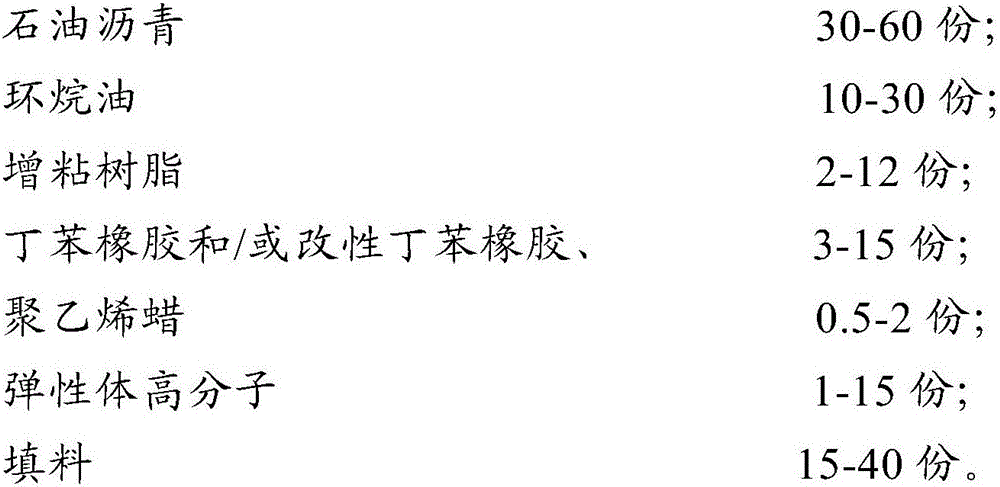

[0024] This embodiment provides a self-adhesive asphalt compound, the raw material formula of which includes petroleum asphalt, naphthenic oil, tackifying resin, styrene butadiene rubber and / or modified styrene butadiene rubber, polyethylene wax, elastomeric polymer, and filler. The self-adhesive asphalt rubber has high initial adhesion and high heat resistance.

[0025] The self-adhesive bituminous material with high initial adhesion and high heat resistance in this embodiment is used as the bonding layer for bonding the self-adhesive waterproofing membrane and the base layer (such as roofing). The polyethylene wax and petroleum in the bonding layer The asphalt cross-linking reaction, thereby improving the heat resistance of the self-adhesive asphalt compound. The self-adhesive asphalt rubber has good adhesion performance, fully adheres to the base layer, is firmly bonded, and can withstand heat above 90°C, and its low temperature flexibility can reach -30°C. Since the self-adhe...

Embodiment 2

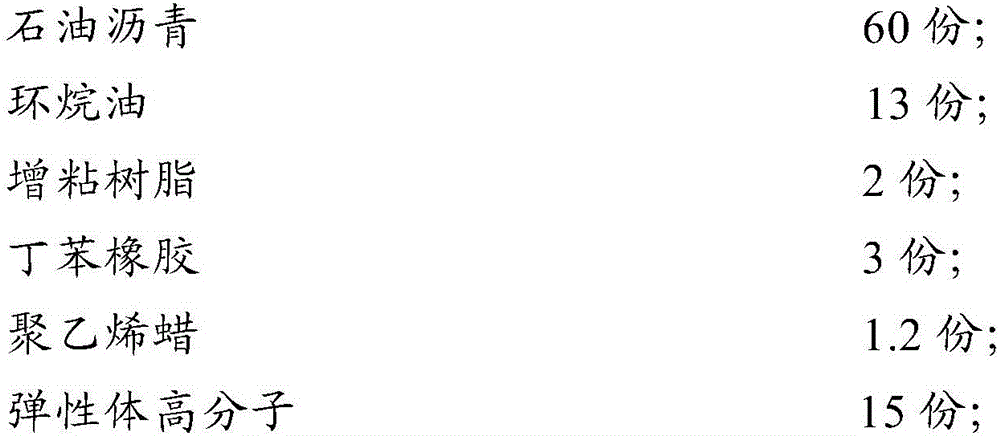

[0027] This embodiment provides a self-adhesive asphalt compound, the raw material formula of which includes the following weight components:

[0028]

[0029]

[0030] The self-adhesive asphalt rubber has high initial adhesion and high heat resistance.

[0031] The molecular weight of polyethylene wax is 8000.

[0032] The petroleum pitch is heavy duty petroleum pitch No. 70.

[0033] The tackifying resin is hydrogenated rosin phenol.

[0034] The elastomeric polymer is a mixture of styrene-butadiene-styrene block copolymer (SBS) (weight parts ratio is 2:3).

[0035] The filler is kaolin.

[0036] This embodiment provides a method for preparing the above-mentioned self-adhesive asphalt rubber, which includes the following steps: mixing materials in a raw material formula to obtain a self-adhesive asphalt rubber.

Embodiment 3

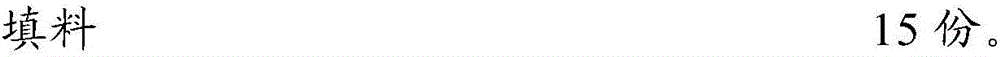

[0038] This embodiment provides a self-adhesive asphalt compound, the raw material formula of which includes the following weight components:

[0039]

[0040] The molecular weight of polyethylene wax is 10,000.

[0041] Petroleum asphalt is a mixture of heavy-duty petroleum asphalt No. 70 and heavy-duty petroleum asphalt No. 130, wherein the weight ratio of heavy-duty petroleum asphalt No. 70 and heavy-duty petroleum asphalt No. 130 is 1:1.

[0042] The tackifying resin is rosin.

[0043] The ratio of parts by weight of styrene butadiene rubber and modified styrene butadiene rubber is 2:1. The emulsion polymerization type styrene-butadiene rubber is prepared by grafting, adding an antioxidant, and adding a release agent to obtain a modified styrene-butadiene rubber, and the grafting group monomer is styrene. The weight ratio of the grafted emulsion-polymerized styrene-butadiene rubber: antioxidant: release agent is 92:1:7.

[0044] The elastomeric polymer is a polyolefin elastomer (P...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com