Novel movable silo for dry-mixed mortar

A technology of dry-mixed mortar and moving cylinder, which is applied in the direction of large containers, loading/unloading, conveyors, etc., which can solve problems such as easy wear and tear, impact of waste gas treatment, material segregation, etc., to reduce extrusion force and friction, and reduce Adverse effects, effects of improving segregation phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with specific examples, but the protection scope of the present invention is not limited thereto.

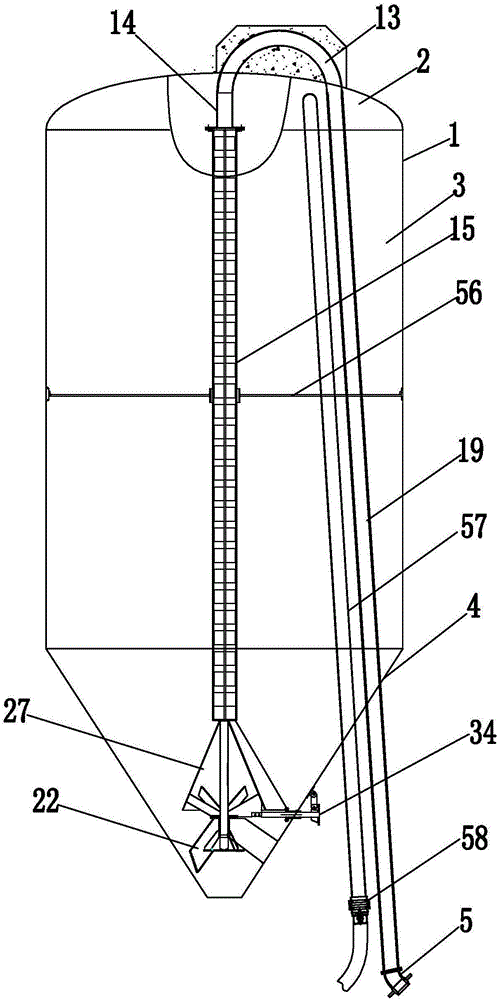

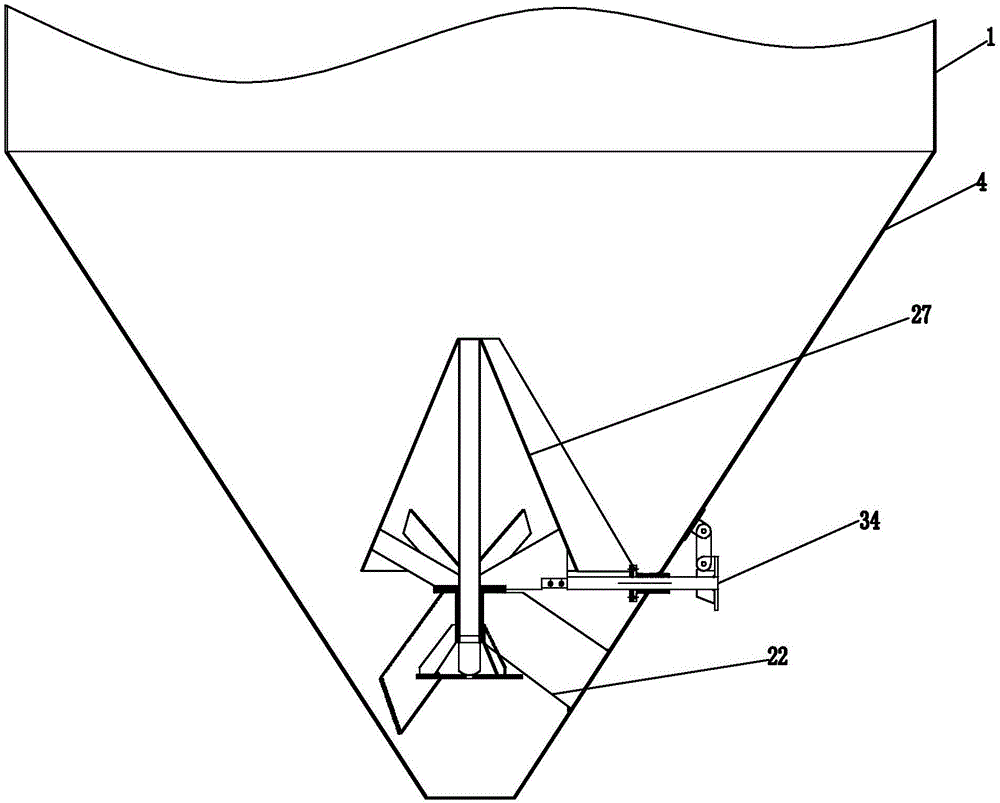

[0044] Such as Figure 1-20 As shown, the novel dry-mixed mortar mobile silo of the present invention includes a mobile silo body 1 on which an air blowing feed structure, a discharge structure and an air outlet structure are installed, and the air blow feed structure includes a feed Straight pipe 19, one end of the feeding straight pipe 19 is connected with the adjustment pipe joint assembly 5, the other end of the feeding straight pipe 19 is connected with the feeding elbow 13, and the end of the feeding elbow 13 is connected with the feed pipe 14 , the guide pipe 14 is connected with a cage-shaped discharge pipe 15, and the cage-shaped discharge pipe 15 is provided with a hoop 56 for limiting the vibration amplitude of the cage-shaped discharge pipe 15, while moving the silo body 1 during handling Pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com