Machining method for hot stamping part based on self-resistance heating performance gradient

A processing method, hot stamping technology, applied in the processing field of hot stamping parts, can solve the problems of large residual stress, large temperature gradient, difficult to realize, etc., and achieve the effects of improving comprehensive collision performance, reducing blank oxidation, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 This embodiment selects high-strength steel plate for use

[0034] a. Carry out force analysis on high-strength steel plates, and mark the collision energy-absorbing area and high-strength area;

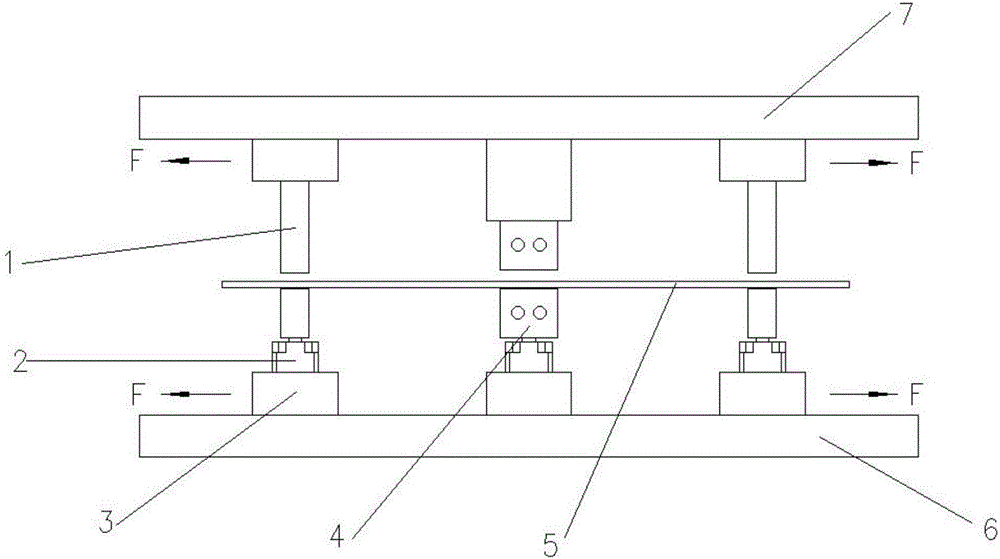

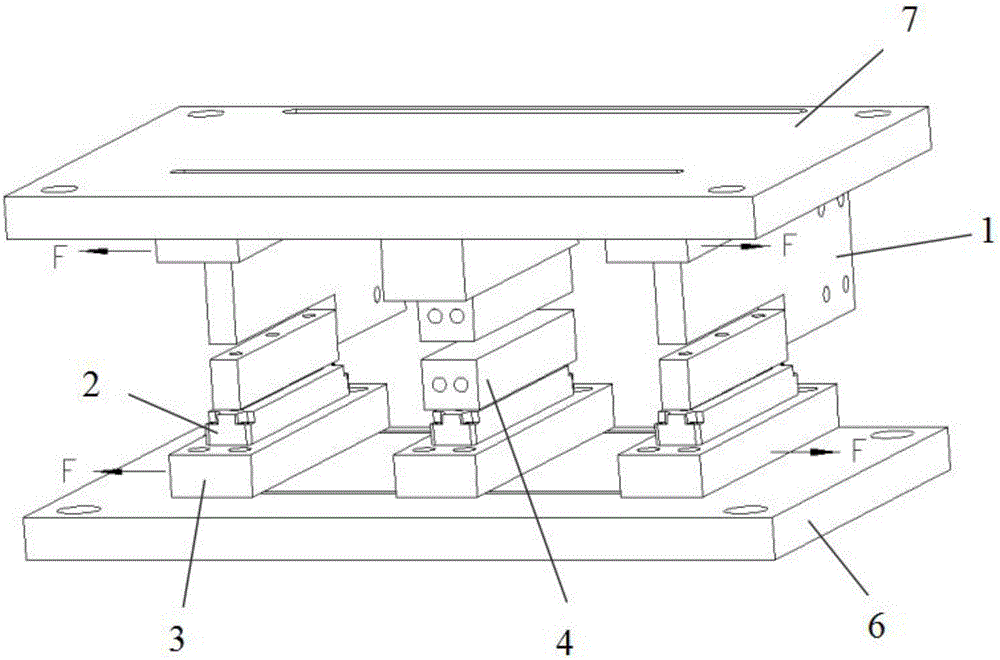

[0035] b. Cut the high-strength steel plate into a certain shape, place it between the electrodes on both sides of the high-power power supply, and apply clamping force to the high-strength steel plate through the ejection cylinder 2 to fasten it. The positive and negative poles of the electrodes on both sides are respectively Connected to both ends of the high-strength steel plate;

[0036] c. For the position and area corresponding to the high-strength steel plate in the collision energy-absorbing area in step a, copper blocks with low resistivity are arranged, and the impact energy-absorbing area of the high-strength steel plate will be short-circuited through the action of the copper block, thereby forming a low-temperature zone. The corresponding high-stre...

Embodiment 2

[0043] Embodiment 2 This embodiment selects high-strength steel plate for use

[0044] The implementation steps of this embodiment 2 are basically the same as that of embodiment 1, the only difference is that step d of embodiment 2 is to heat the high-strength region (high temperature region) corresponding to the high-strength steel plate to 1000 degrees within 20 seconds, and the same as The temperature of the collision energy-absorbing area (low temperature area) where the copper block contacts is maintained between 420 and 750 degrees.

[0045] The tensile strength of the high-temperature region of the high-strength steel plate obtained in Example 2 reaches above 1600 MPa, while the corresponding low-temperature region of the copper block can obtain a tensile strength between 800-1200 MPa according to different temperatures.

Embodiment 3

[0046] Embodiment 3 This embodiment selects titanium alloy plate

[0047] a. Carry out force analysis on the titanium alloy plate, and mark the collision energy-absorbing area and high-strength area;

[0048] b. Cut the titanium alloy plate with a thickness of 2mm into a certain shape, place it between the electrodes on both sides of the high-power power supply, and apply a clamping force to the titanium alloy plate through the ejection cylinder to tighten it. The negative electrode is respectively connected to both ends of the titanium alloy plate;

[0049] c. For the position and area corresponding to the titanium alloy plate in the collision energy-absorbing area in step a, copper blocks with low resistivity are arranged, and the impact energy-absorbing area of the titanium alloy plate will be short-circuited through the action of the copper block, thereby forming a low-temperature zone. The corresponding high-strength area is the high-temperature area;

[0050] d. A hi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com