Explosion-proof fuel oil dehydration and deoxygenation device

An explosion-proof, fuel oil technology, applied in the directions of liquid degassing, separation methods, chemical instruments and methods, etc., can solve the problems of inability to online dehydration and deoxidation, no explosion-proof function, small fuel flow rate, etc. Good economic benefits and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

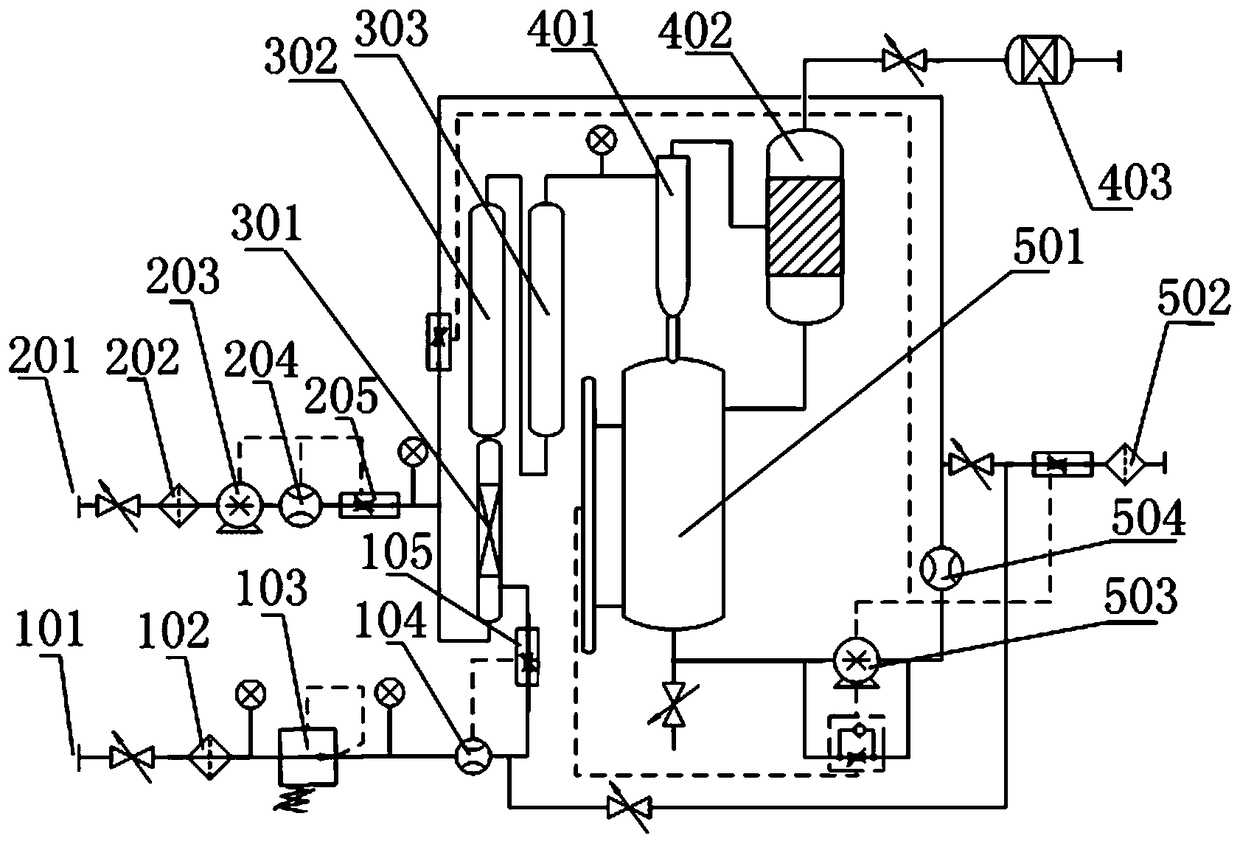

[0021] like figure 1 The explosion-proof fuel oil dehydration and deoxygenation device shown includes an air intake pipeline system, an oil intake pipeline system, an oil-gas mixing system, an oil-gas separation system, a product oil delivery system, and an automatic control system; the oil-gas mixing system includes an oil inlet and an air inlet The Venturi atomizing mixer, gas-liquid static mixer Ⅰ, the gas-liquid outlet of the Venturi atomizing mixer and the gas-liquid inlet of the gas-liquid static mixer Ⅰ are connected by pipelines; the gas-liquid static mixing system is added to the oil-gas mixing system The gas-liquid inlet of the gas-liquid static mixer II is connected to the gas-liquid outlet of the gas-liquid static mixer I through pipelines, and the gas-liquid outlet of the gas-liquid static mixer II is connected to the oil-gas separation system.

[0022] By adding the gas-liquid static mixer II, compared with a single gas-liquid static mixer, the capacity of oil an...

Embodiment 2

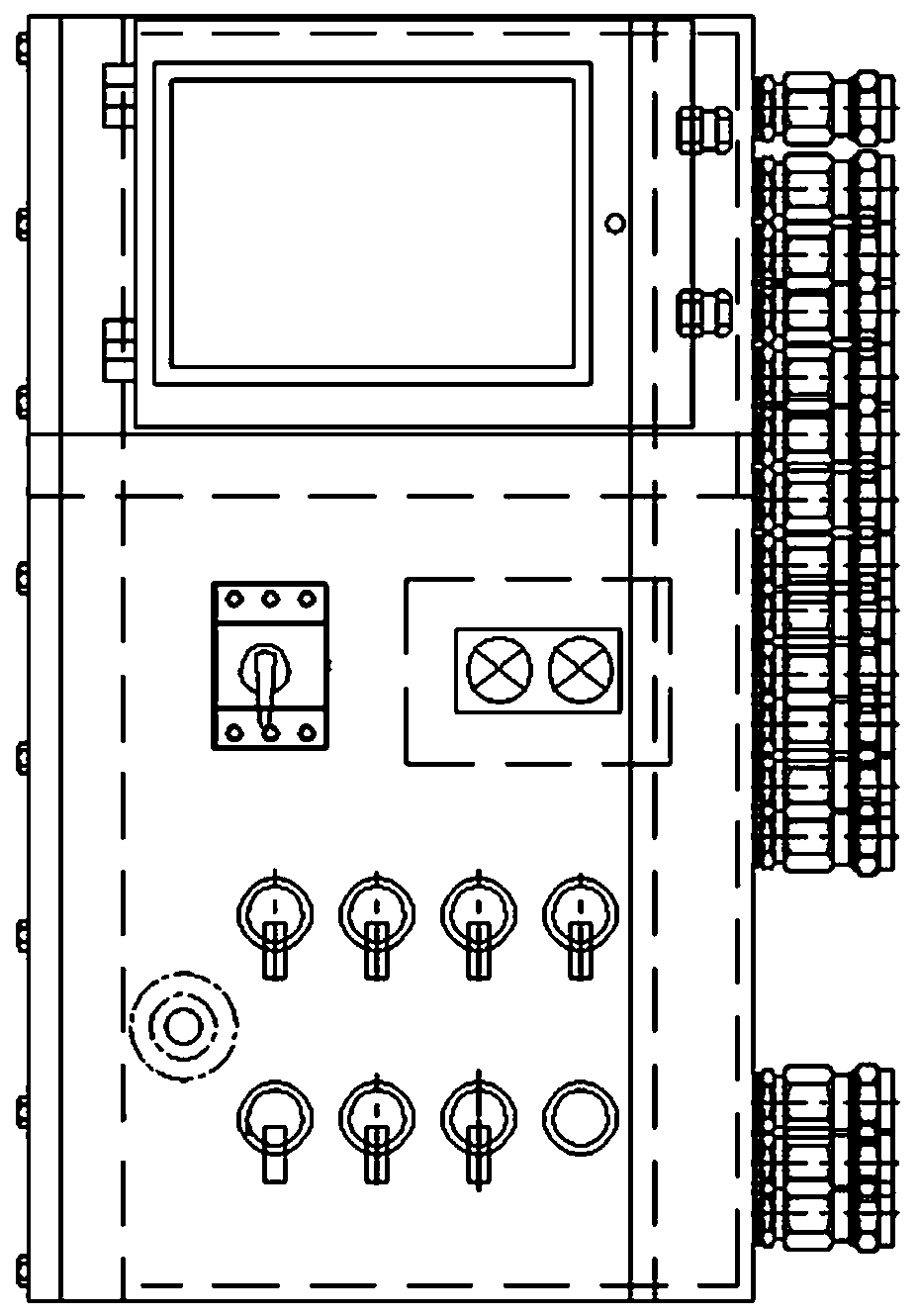

[0040] On the basis of the foregoing embodiment 1, in order to adapt to different working environments and different customer requirements, an explosion-proof device and an explosion-proof design of the entire equipment are added.

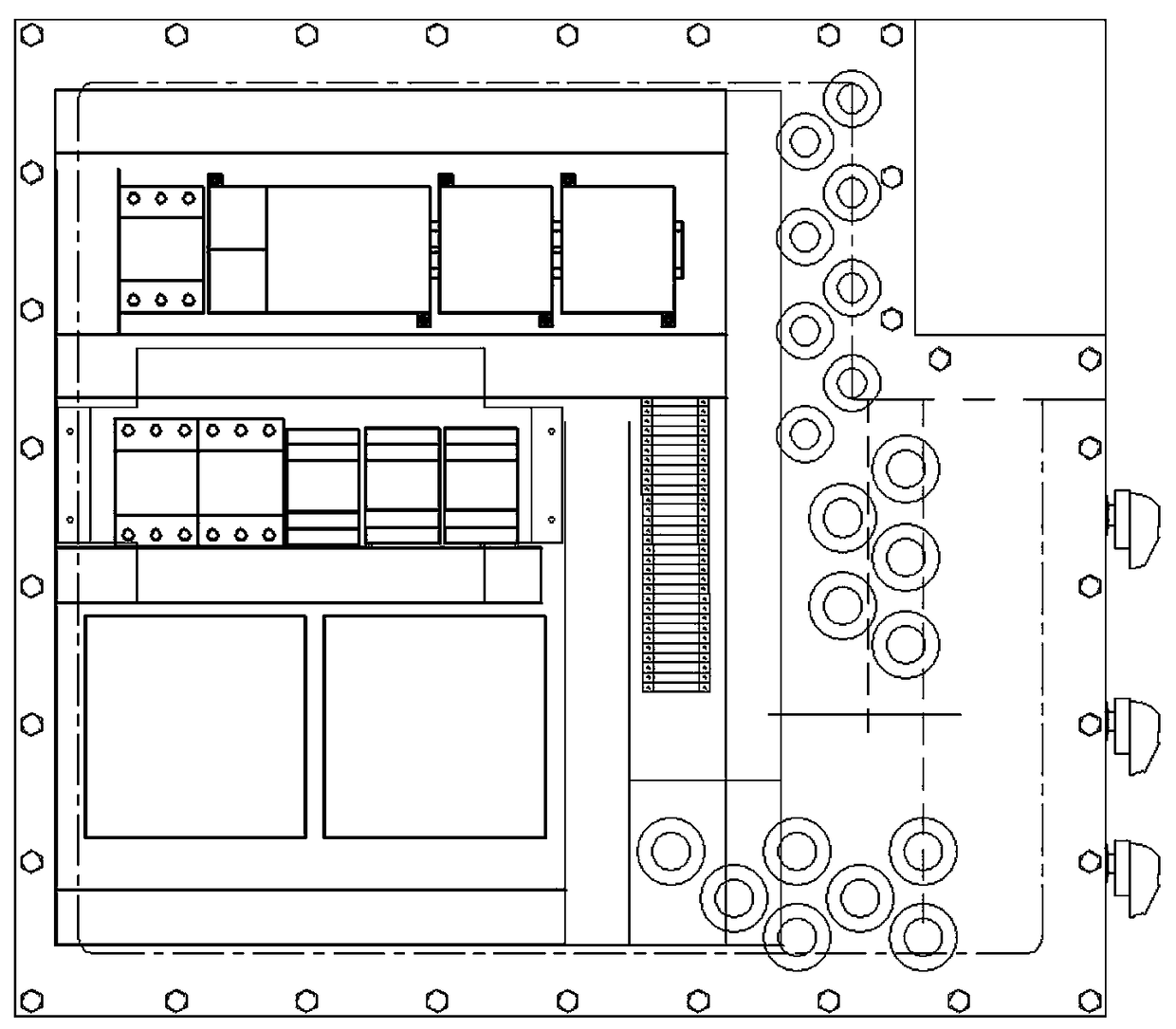

[0041] The control box is an explosion-proof control box, and the explosion-proof control box has a shell that can isolate sparks or electric arcs generated by electrical components from the explosive gas in the surrounding environment; it also includes an explosion-proof switch and a cable sealing structure, which are respectively arranged in the explosion-proof control on the casing of the box.

[0042] Among them, the explosion-proof control box is used to accommodate PLC controllers, frequency conversion controllers and other electrical components; the control cable enters the explosion-proof control box through the cable sealing structure, and the cable sealing structure can tightly wrap the cables passing through the house, further strengtheni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com