Muffler transmission loss testing system and muffler transmission loss testing method for aiming at aerodynamic noise

A technology of transmission loss and aerodynamic noise, applied in the direction of vehicle testing, machine/structural component testing, instruments, etc., to achieve the effect of convenient operation, high precision and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

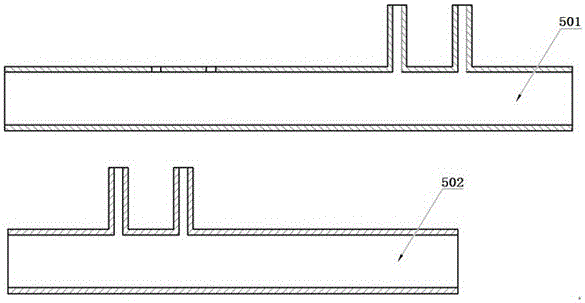

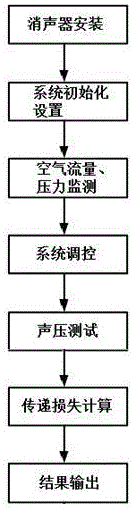

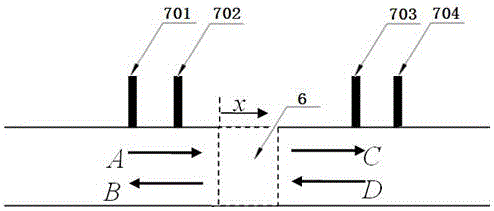

[0030] A muffler transmission loss test system for aerodynamic noise such as figure 1 As shown, it includes frequency conversion centrifugal fan 1, fan noise muffler 2, air flow sensor 3, air pressure sensor 4, standing wave tube 5, muffler to be tested 6, microphone group 7, electronic air pressure relief valve 8, pressure relief valve muffler 9. A / D conversion board 10, gain amplifier 11 and computer 12. The air outlet of the variable frequency centrifugal fan 1 is connected to the intake end of the fan noise muffler 2; the electronic air pressure relief valve 8 and the pressure relief valve muffler 9 are installed in series on the side branch pipe of the centrifugal fan 1; one end of the front pipe of the standing wave pipe 5 Connect the air outlet end of the fan noise muffler 2, and the other end is connected to the inlet end of the muffler 6 to be tested; the air outlet end of the muffler 6 to be tested is connected to one end of the rear pipe of the standing wave tube 5;...

Embodiment 2

[0044] The difference between the muffler transmission loss test system for aerodynamic noise in this embodiment and Embodiment 1 is that, in addition to performing amplitude calibration on each microphone, phase calibration should also be carried out so that the lag of the four microphones at the same time The angle is equal to 0, so that they are synchronized in phase, so that the sound pressure signal collected by the microphone is more accurate, and the measurement error is eliminated to the greatest extent.

Embodiment 3

[0046] The difference between the muffler transmission loss test system for aerodynamic noise in this example and Example 1 is that in order to ensure the accuracy and consistency of the test results, the temperature, humidity, and atmospheric pressure levels of the test environment should be kept stable, and there should be no electromagnetic interference around And the background noise should be less than 36 decibels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com