Airtight and two-level porous gas-liquid recycling device for immersion-type photoetching machine

A gas-liquid recovery and gas-sealing technology, which is used in photolithographic process exposure devices, microlithography exposure equipment, etc., can solve problems such as liquid leakage, sealing gas entrainment, vibration, etc., to slow down flow rate, reduce vibration, and reduce The effect of small shocks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation process of the present invention will be described in detail below in conjunction with the drawings and embodiments.

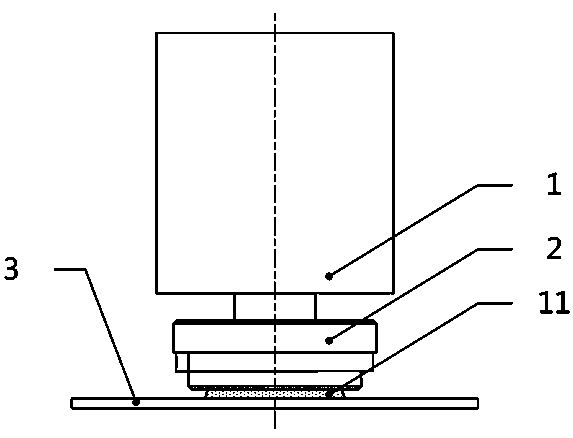

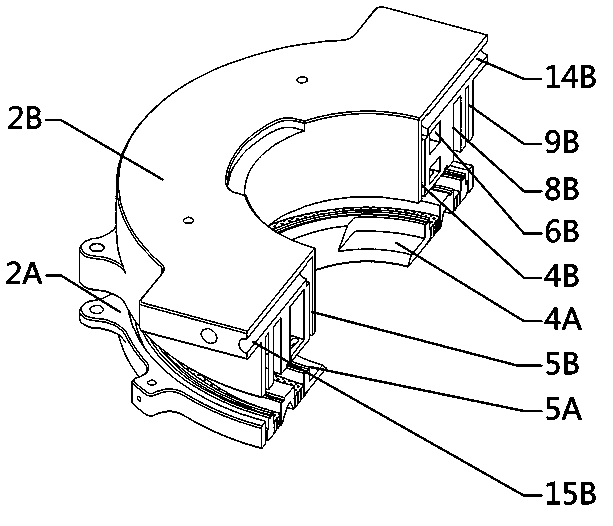

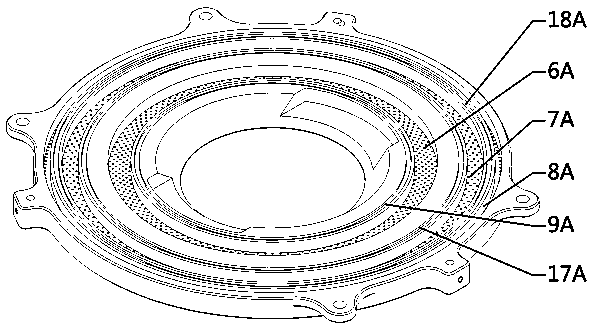

[0037] Such as figure 1As shown, the present invention includes an air-tight and gas-liquid isolation device 2 installed between the projection objective lens group 1 and the silicon wafer 3 in the immersion lithography machine, and the air-tight and gas-liquid isolation device 2 is installed between the projection objective lens group 1 and the silicon wafer 3. Between the silicon wafers 3, the air-tight and gas-liquid isolation device 2 has a central through hole. The main function of the air-tight and gas-liquid isolation device 2 is to limit the immersion liquid 11 directly below the projection objective lens group 1, from which the projection objective lens group The light emitted from 1 passes through the central through hole of the air-tight and gas-liquid isolation device 2 and then enters the gap flow field, that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com