Waste LED lighting bulb recycling method

A technology of LED lighting and recycling method, which is applied in photography technology, equipment, photography auxiliary technology, etc., can solve problems such as waste of resources, achieve high recycling efficiency, improve recycling efficiency, and have good compatibility in comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

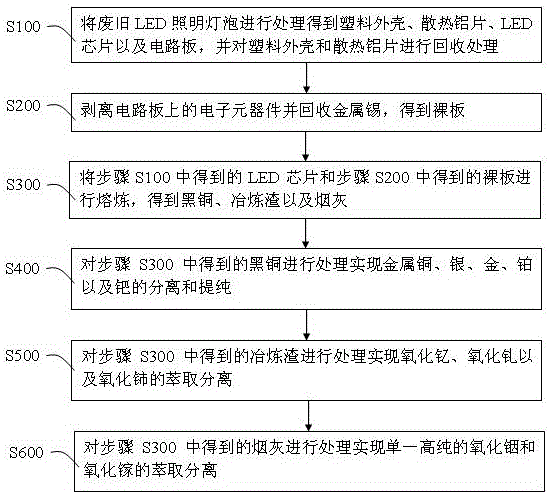

Method used

Image

Examples

Embodiment 1

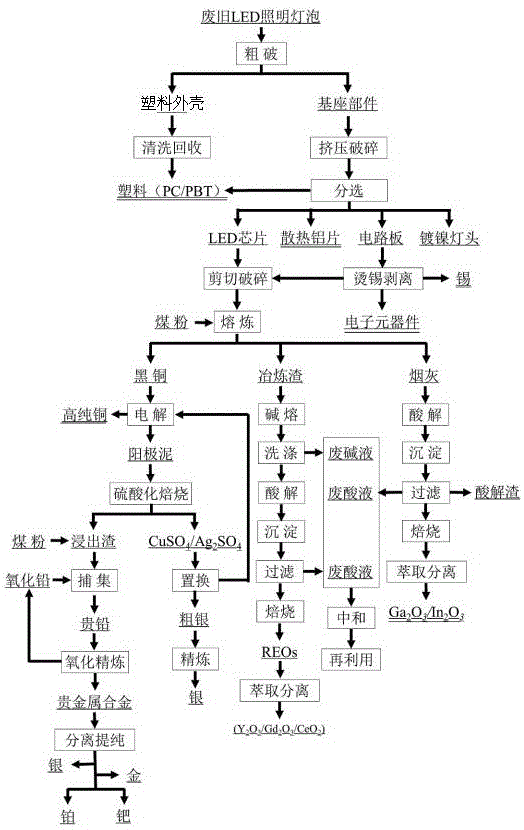

[0063] Waste LED lighting bulbs are roughly broken, squeezed and broken, and plastic shells are obtained by screening, magnetic separation and air separation (recycled after cleaning, including PC (Polycarbonate, polycarbonate / PBT (Polybutylene Terephthalate, polyparaphenylene) Butylene glycol diformate), etc.), heat-dissipating aluminum sheets, LED chips and circuit boards. The circuit boards are placed in a tinning furnace at a temperature of 250°C for 15s, and the melted metal tin is recovered. Stripping electronic components The final bare board and LED chips are cut into 1-5cm size by shearing and then melted in the smelting furnace, blown into air and coal powder, and the smelting temperature is 1200°C. Among them, the organic matter in the bare board provides energy and reduces dust. The amount of coal added. After smelting, black copper, smelting slag and soot are obtained. Due to the difference in the physical and chemical properties of each metal, copper is used as a ...

Embodiment 2

[0065] Waste LED lighting bulbs are roughly crushed, squeezed and broken, and then screened, magnetically separated and air-separated to obtain plastic shells (recycled after cleaning, including PC / PBT, etc.), heat-dissipating aluminum sheets, LED chips and circuit boards. . The circuit board is placed in a tin ironing furnace at a temperature of 300°C for 10 seconds. The melted metal tin is recovered, and the bare board and LED chip after stripping off the electronic components are cut and broken (cut into 1~5cm size) and then enter The smelting furnace is smelted, air and pulverized coal are blown in, and the smelting temperature is 1250 ° C. Among them, the organic matter in the bare plate provides energy and reduces the amount of pulverized coal added. After smelting, black copper, smelting slag and soot are obtained. Due to the different physical and chemical properties of each metal, copper is used as a precious metal collector to form a copper alloy containing gold, sil...

Embodiment 3

[0067]Waste LED lighting bulbs are roughly crushed, squeezed and broken, and then screened, magnetically separated and air-separated to obtain plastic shells (recycled after cleaning, including PC / PBT, etc.), heat-dissipating aluminum sheets, LED chips and circuit boards. . The circuit board is placed in a tin ironing furnace at a temperature of 350°C for 5 seconds. The melted metal tin is recovered, and the bare board and LED chip after stripping off the electronic components are cut and broken (cut into 1~5cm size) and then enter The smelting furnace is smelted, air and pulverized coal are blown in, and the smelting temperature is 1300 ° C. Among them, the organic matter in the bare plate provides energy and reduces the amount of pulverized coal added. After smelting, black copper, smelting slag and soot are obtained. Due to the different physical and chemical properties of each metal, copper is used as a precious metal collector to form a copper alloy containing gold, silve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com