Laser remelting method for ultrasonic spraying of WC-12Co coating

A technology of supersonic spraying and laser remelting, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., can solve the problems such as the decrease of the bonding strength between the coating and the substrate, and achieve improved wear resistance and uniform thickness , The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] (1) Use 180#-1000# sandpaper to polish the surface of the substrate, clean it with absolute ethanol, and degrease with acetone to remove grease and sundries on the surface of the sample to ensure that the surface cleanliness of the substrate reaches Sa3 level.

[0012] (2) Use cast iron sand with a particle size of 1mm as abrasive grains, compressed air pressure > 0.8MPa, sandblasting distance of 200mm, and sandblasting angle of 20°, so that the roughness can reach RZ60μm.

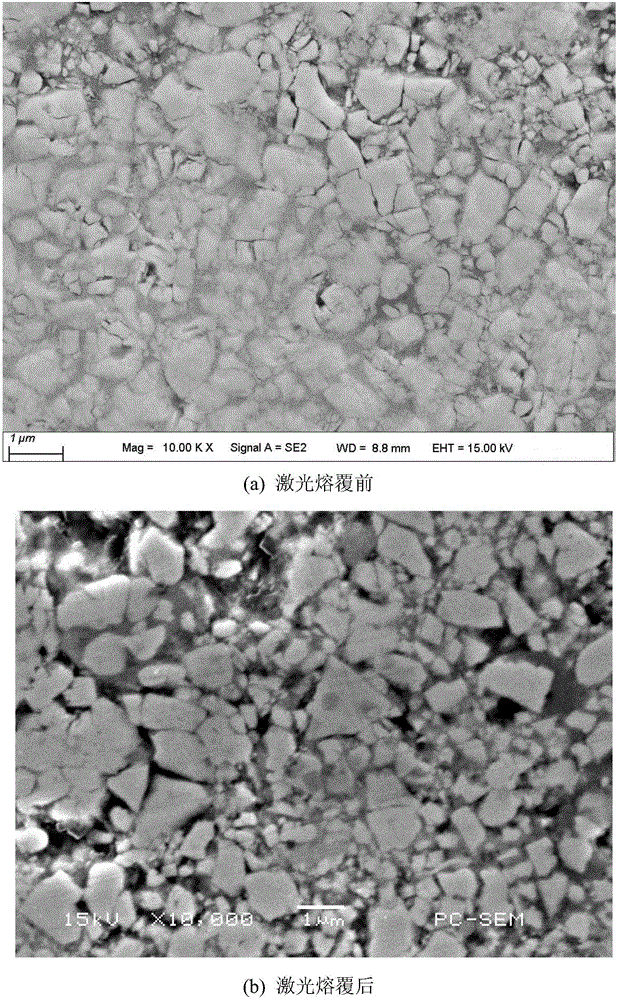

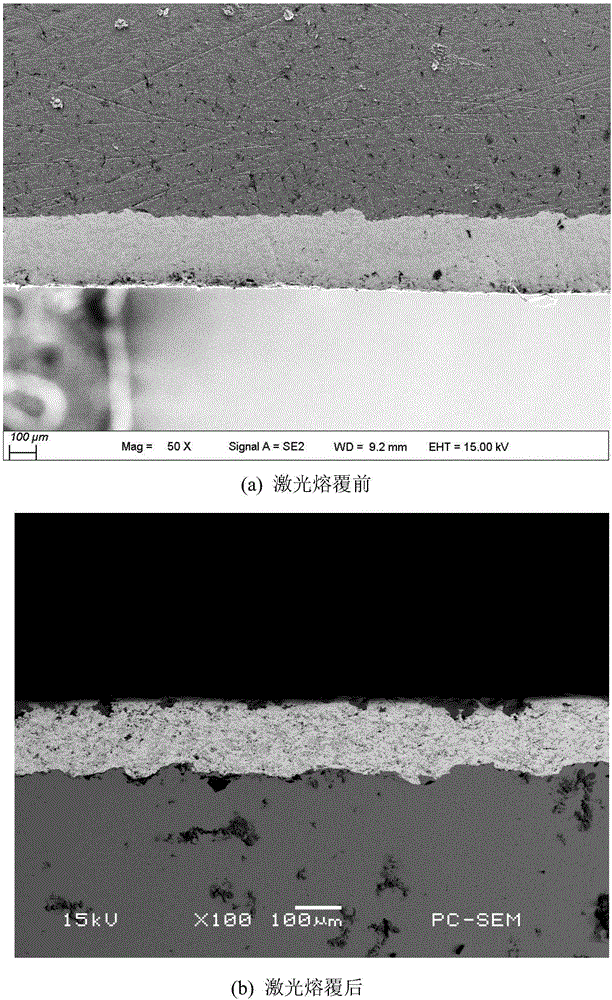

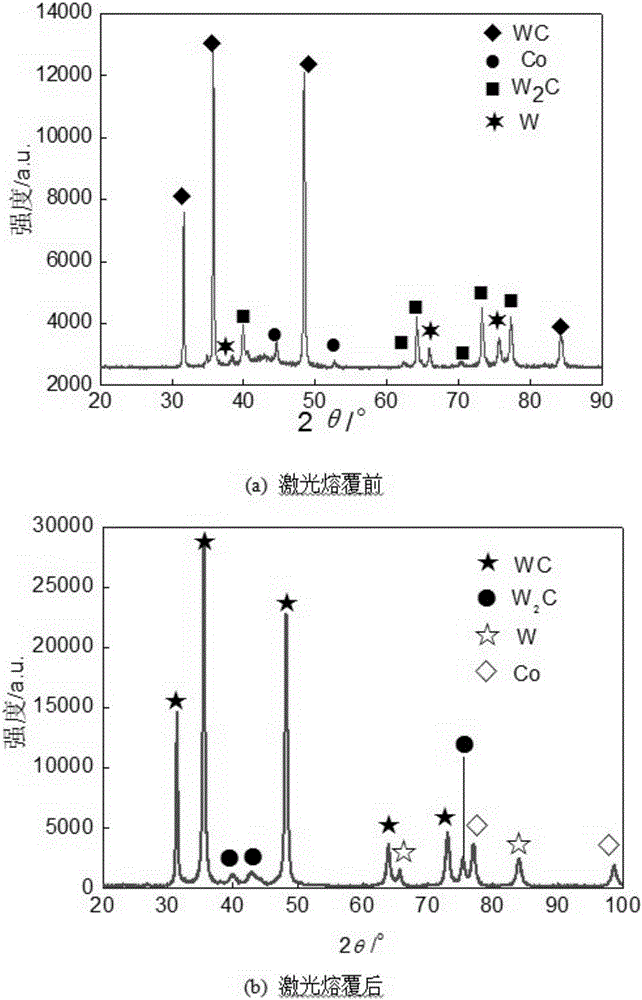

[0013] (3) Dry the WC-12Co powder with a DHG-9145A type electric heating constant temperature blast drying oven for 3 hours to ensure that the sprayed powder is dry, and then spray on the XM-8000 supersonic flame spraying system, using aviation kerosene as fuel, high pressure O 2 As a combustion-supporting gas, N 2 As the powder feeding gas, the spray oil pressure is 1.25MPa, the oxygen pressure is 1.58MPa, the water temperature is 40°C, and the spray gun pressure is 0.95MPa, so that the surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com