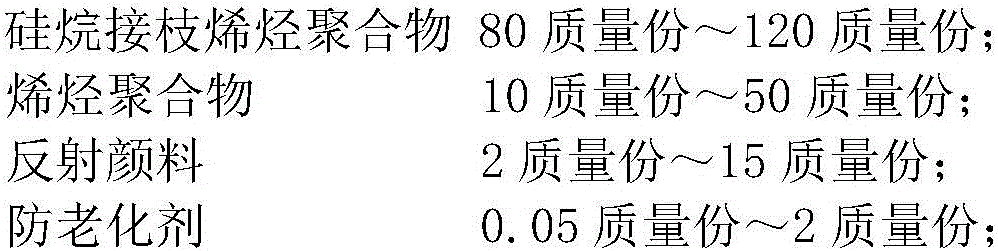

Photovoltaic packaging adhesive film

An encapsulation film and photovoltaic technology, applied in photovoltaic power generation, adhesives, grafted polymer adhesives, etc., can solve the problems of affecting the reflection performance, reducing the wettability of inorganic materials, and rough contact surfaces, so as to ensure safety. and reliability, excellent bonding properties, good anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] 1.2g of anti-aging agent (containing 0.3g of 2,2'-dihydroxy-4-methoxybenzophenone as a UV absorber, 0.5g of Lowilite-62 and Lowilite-94 with a weight ratio of 1:1 Mixture as light stabilizer, 0.4g tetrakis [methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester as antioxidant) and 5g zinc sulfide reflective pigment, 20g ethylene-octene random copolymer (ENGAGE 8130 of Dow Chemical, Tg-59°C) was mixed to obtain white masterbatch after granulation and drying by twin-screw extruder, then white masterbatch, 10g low Density polyethylene (COSMOTHENE F410-1 of Singapore polyolefin, melting peak temperature 111 ℃), 30g silane grafted ethylene-octene copolymer H-1 (laboratory preparation, grafting rate 1.8%, at 190 ℃, 2.16kg The melt index under test conditions is 3.3g / 10min), 70g silane grafted ethylene-propylene copolymer H-2 (laboratory preparation, grafting rate 1.6%, the melt index under 190 ℃, 2.16kg test conditions is 1.2 g / 10min, melting peak tem...

Embodiment 2

[0066] 0.05g of anti-aging agent (containing 0.01g of 2,2'-dihydroxy-4-methoxybenzophenone as a UV absorber, 0.02g of Lowilite-62 and Lowilite-94 with a weight ratio of 1:1 The mixture is used as light stabilizer, 0.02g tetrakis [methyl-β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester as antioxidant) and 12g zinc oxide reflective pigment, 5g of ethylene butene copolymer (ENR 7447 of Dow Chemical, Tg-57°C) was mixed and then granulated and dried by twin-screw extruder to obtain white masterbatch, then white masterbatch, 5g low density polyethylene (Taiju's LINATHENE LL110, the melting peak temperature is 122°C, and the melt flow rate measured under the condition of 190°C 2.16kg is 1g / 10min), 50g of silane grafted ethylene-octene copolymer H-1 (prepared in the laboratory, Grafting rate 1.0%, the melt index under 190 ℃, 2.16KG test conditions is 7.0g / 10min), 50g silane grafted 4-methyl-1-pentene homopolymer H-2 (prepared in laboratory, grafted branch rate ...

Embodiment 3

[0068] 2.0g of anti-aging agent (containing 0.3g of 2,2'-dihydroxy-4-methoxybenzophenone as a UV absorber, 1.0g of Lowilite-62 and Lowilite-94 with a weight ratio of 1:1 The mixture is used as a light stabilizer, 0.7 g of tetrakis [methyl-β- (3, 5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester as an antioxidant) and 8 g of boron nitride reflective pigment , 30g of propylene ethylene copolymer (VERSIFY 3401 of Dow Chemical, glass transition temperature -32°C) was mixed and granulated and dried by a twin-screw extruder to obtain a white masterbatch, and then the white masterbatch, 10g of linear low-density polymer Ethylene (UNITENE LH503 from Taiju, melting peak temperature 130°C), 40g of silane-grafted ethylene-1-pentene copolymer H-1 (prepared in the laboratory, grafting rate 2.0%, under the test conditions of 190°C and 2.16kg The melt index is 2.2g / 10min), 70g silane grafted low-density polyethylene H-2 (prepared in the laboratory, grafting rate 1.6%, the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com