Method for pretreating heavy oil based on self-assembling effect of heavy aromatics in subcritical/supercritical water and application

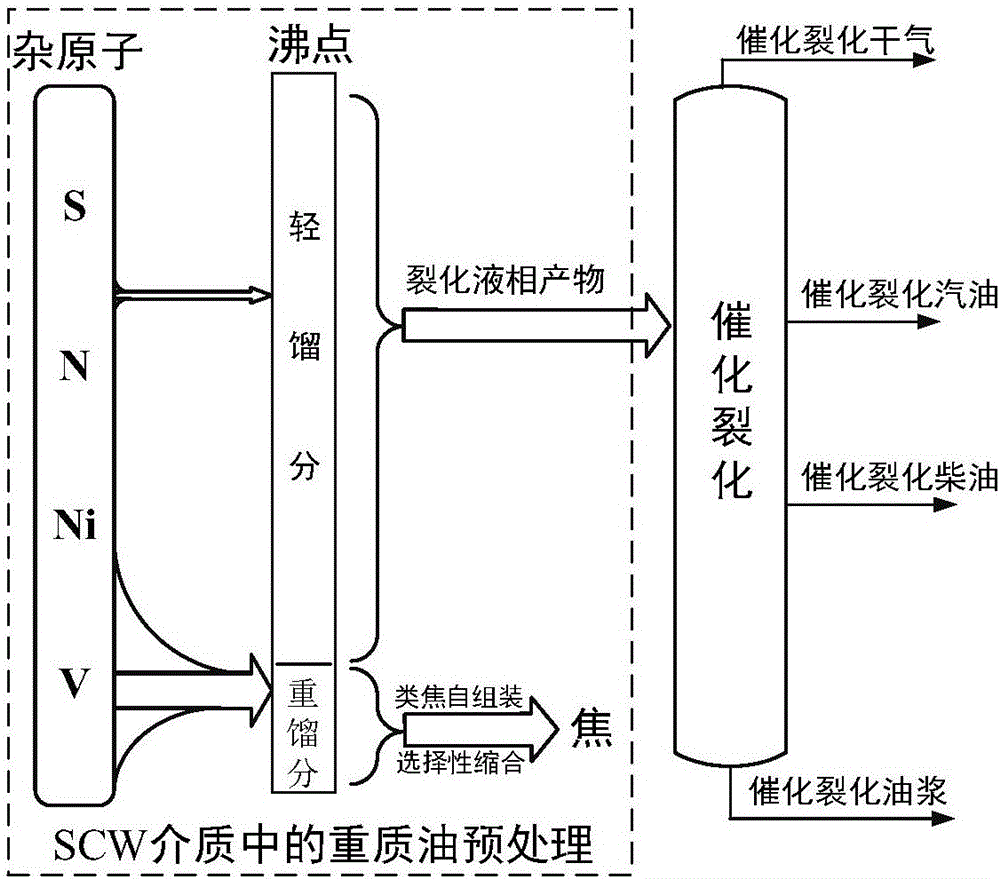

A technology for supercritical water and heavy oil, which is applied in the treatment of hydrocarbon oil, petroleum industry, catalytic reforming of naphtha, etc., and can solve problems such as loss of light distillate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] For the pretreatment under the supercritical water environment, 7.5g of raw oil (properties are shown in Table 1) and 30g of water are added in a high-pressure reactor with a capacity of 100ml. With high purity N 2 After purging for 10 minutes, the closed reactor was heated from room temperature at a rate of 15 K / min, and the stirring rate was kept at 700 rpm during the process. After reaching the designated reaction temperature of 375°C, keep it for 10-120 minutes. Then the reactor was cooled by air to terminate the reaction.

[0066] for N 2 In the comparative pretreatment experiment under ambient conditions, 30 g of raw material oil was added to a high-pressure reactor with a capacity of 100 ml. After high-purity N 2 Filled with 8.0-9.0MPa high-purity N after purging 2 . The closed reactor was heated at a rate of 15K / min from normal temperature, and the stirring rate was kept at 700rpm during the process. After reaching the reaction temperature, maintain a cer...

Embodiment 2

[0074] Add 8.3g raw material oil (property as shown in Table 2) and 25g water in the high-pressure reactor that capacity is 100ml. With high purity N 2 After purging for 10 minutes, the closed reactor was heated from room temperature at a rate of 15 K / min, and the stirring rate was kept at 700 rpm during the process. After reaching the designated reaction temperature of 390°C, keep it for 90 minutes. Then the reactor was cooled by air to terminate the reaction. In order to keep the experimental error of product distribution below 5%, all reaction processes were repeated more than three times.

[0075] Table 2 Properties of raw material heavy oil

[0076]

[0077] After the pretreatment in the SCW environment, the analysis results of the cracked liquid phase products are shown in Table 3.

[0078] Table 3 Properties of liquid phase reaction products after SCW environmental pretreatment

[0079]

Embodiment 3

[0081] Add 6.7g raw material oil (property as shown in Table 4) and 40g water in the high-pressure reactor that capacity is 100ml. With high purity N 2 After purging for 10 minutes, the closed reactor was heated from room temperature at a rate of 15 K / min, and the stirring rate was kept at 700 rpm during the process. After reaching the designated reaction temperature of 360°C, keep it for 60 minutes. Then the reactor was cooled by air to terminate the reaction. In order to keep the experimental error of product distribution below 5%, all reaction processes were repeated more than three times.

[0082] Table 4 Properties of raw material heavy oil

[0083]

[0084] After the pretreatment in the subcritical water environment, the analysis results of the cracked liquid phase products are shown in Table 5.

[0085] Table 5 Properties of liquid phase reaction products after sub-CW environmental pretreatment

[0086]

[0087] The method of heavy oil pretreatment and upgrad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com