Rotary tooth type crusher

A crusher and tooth type technology, which is applied in the field of rotary tooth crushers, can solve the problems of large footprint, high cost, and low production efficiency, and achieve the effects of low installation cost, reduced price, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

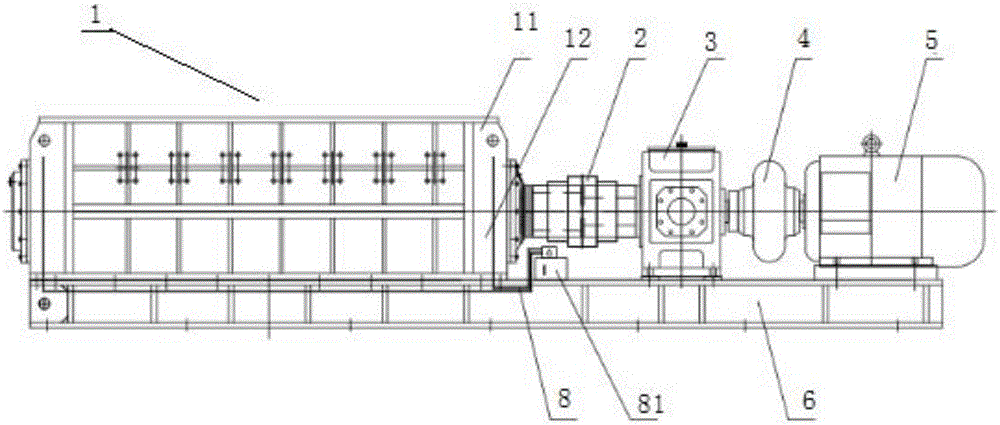

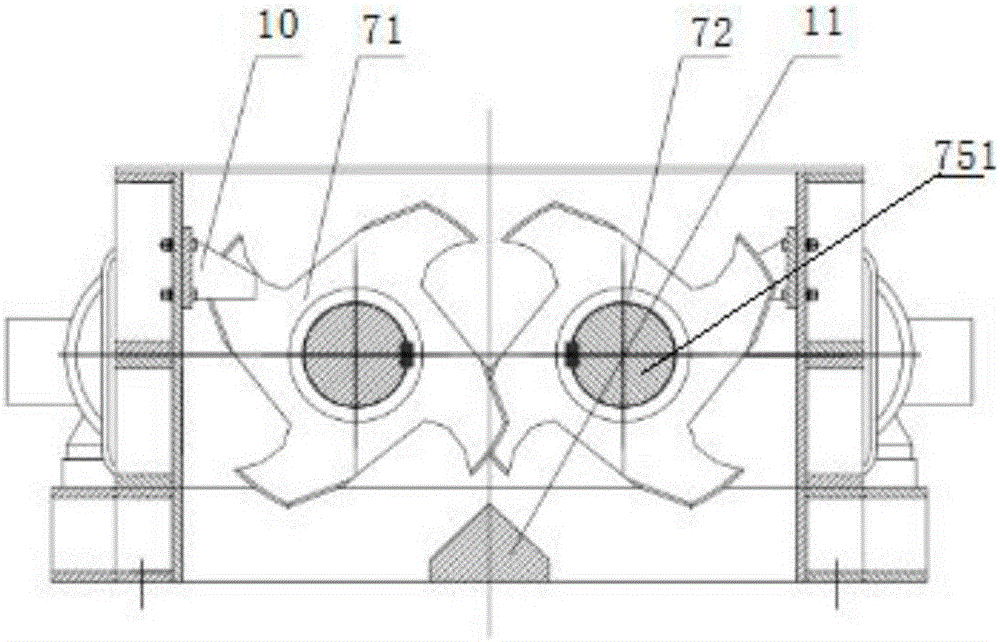

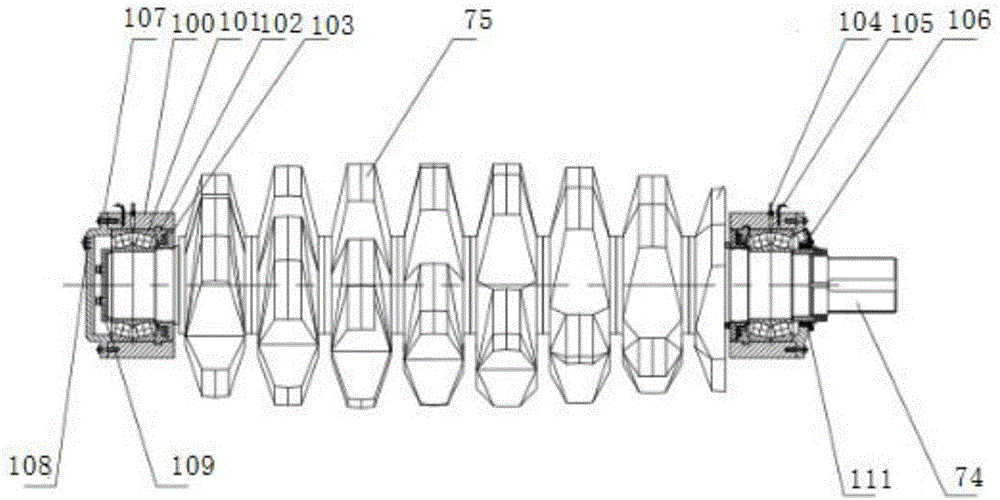

[0028] The invention discloses a rotary tooth crusher, such as figure 1 , 2 And 3 shows crushing chamber 1, drum gear coupling 2, reducer 3, hydraulic coupling 4, motor 5 and base 6, crushing chamber 1, drum gear coupling 2, reducer 3 , hydraulic coupler 4, and motor 5 are connected in sequence and set on the base 6. The crushing chamber 1 includes an upper body 11 and a lower body 12 of the crushing chamber. The upper body 11 of the crushing chamber is arranged above the lower body 12 of the crushing chamber, and the upper body 11 and the lower body 12 of the crushing chamber to form a complete crushing chamber 1, the crushing chamber 1 is provided with a helical tooth spindle 7 for crushin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com