Method for preparing 4,4'-dichlorodiphenyl sulfone

A technology of dichlorodiphenyl sulfone and dichlorodiphenyl sulfoxide, applied in the field of preparation of 4,4'-dichlorodiphenyl sulfone, which can solve the problems of severe equipment corrosion, production equipment hazards, high reaction temperature, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

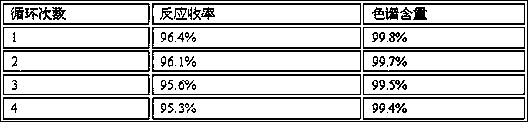

[0016] Take 27.12 g (0.1 mol) of 4,4'-dichlorodiphenyl sulfoxide and dissolve it in 30 mL of dichloropropane and 5 mL of glacial acetic acid, add dropwise 4.0 g of catalyst sulfuric acid with a mass fraction of 50%, and heat at 70 °C Add 15 mL of 30% hydrogen peroxide dropwise, stir and react for 90 minutes, then let it stand to cool to room temperature, filter and separate the solid, wash the solid with a small amount of water, separate the filtrate, take the lower organic layer and concentrate, recover the solvent, crystallize and separate, and combine The solid was dried to obtain 26.8 g of 4,4'-dichlorodiphenyl sulfone, the product yield was 93.2%, the melting point was 147-149°C, and the chromatographic content was 99.3%. The upper layer is an aqueous solution of sulfuric acid and glacial acetic acid, which is recovered for next use.

Embodiment 2

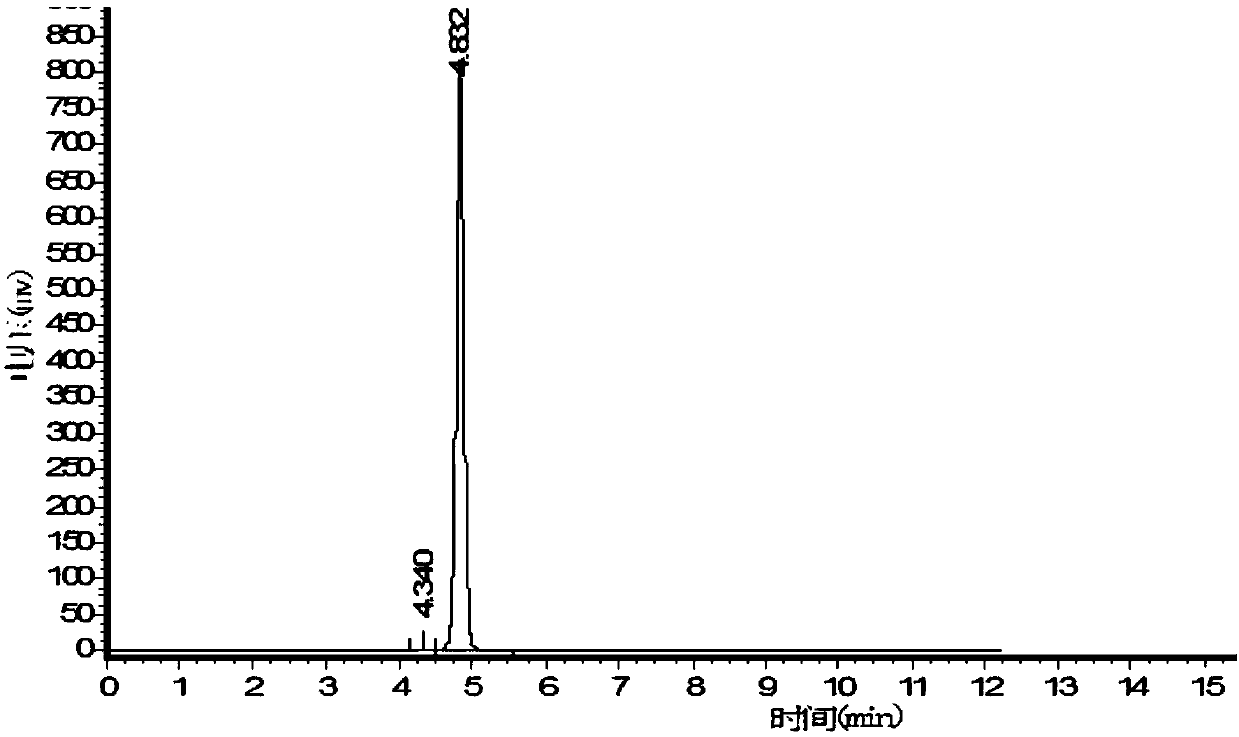

[0018] Take 27.12 g (0.1 mol) of 4,4'-dichlorodiphenyl sulfoxide and dissolve it in 30 mL of dichloropropane and 5 mL of glacial acetic acid, add 6.0 g of catalyst sulfuric acid with a mass fraction of 50% dropwise, and heat at 80 °C Add 10 mL of 40% hydrogen peroxide dropwise, stir and react for 100 minutes, then let stand to cool to room temperature, filter and separate the solid, wash the solid with a small amount of water, separate the filtrate, take the lower organic layer and concentrate, recover the solvent, crystallize and separate, combine The solid was dried to obtain 27.8 g of 4,4'-dichlorodiphenyl sulfone, the product yield was 96.8%, the melting point was 147-149°C, and the chromatographic content was 99.8%. The upper layer is an aqueous solution of sulfuric acid and glacial acetic acid, which is recovered for next use.

Embodiment 3

[0020] Take 271.2 g (1.0 mol) of 4,4'-dichlorodiphenylsulfoxide and dissolve it in 250 mL of dichloropropane and 50 mL of glacial acetic acid, add 60 g of catalyst sulfuric acid with a mass fraction of 50%, and drop it at 80 °C Add 150 mL of 30% hydrogen peroxide, stir and react for 120 minutes, then let it stand to cool to room temperature, filter and separate the solid, wash the solid with a small amount of water, separate the filtrate, take the lower organic layer and concentrate, recover the solvent, crystallize and separate, and combine the solid And dried to obtain 277.1 g of 4,4'-dichlorodiphenyl sulfone, the product yield was 96.5%, the melting point was 147-149°C, and the chromatographic content was 99.7%. The lower layer of the solution is an aqueous solution of sulfuric acid and glacial acetic acid, which is recovered for next use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com