Method for treating high-concentration isobutylene wastewater through PO by-product TBA pyrolysis

A technology for concentrated wastewater and isobutylene, which is used in natural water treatment, heating water/sewage treatment, and water/sewage multi-stage treatment, etc., can solve the problems of long treatment process, high equipment cost, uneconomical and other problems, and achieve low wastewater treatment cost. , The process is simple, no secondary pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 1.83g of ruthenium nitrate and dissolve it in 1L of water, add 5.0g of niobium pentoxide and 116.7g of titanium dioxide, stir continuously for 20min, add sodium hydroxide to adjust the pH to 9, heat to 60°C and stir continuously for 4h, wash the slurry by centrifugation for 3 times, Dry at 110°C for 10h, roast at 400°C for 5h, and then use a mixed gas of 40v% hydrogen and 60v% nitrogen (with a space velocity of 100h -1 ) was reduced and activated at 400°C for 15 hours to prepare a hydrogenolysis catalyst containing 0.48wt% ruthenium, wherein the weight ratio of Nb:Ti was 1:20.

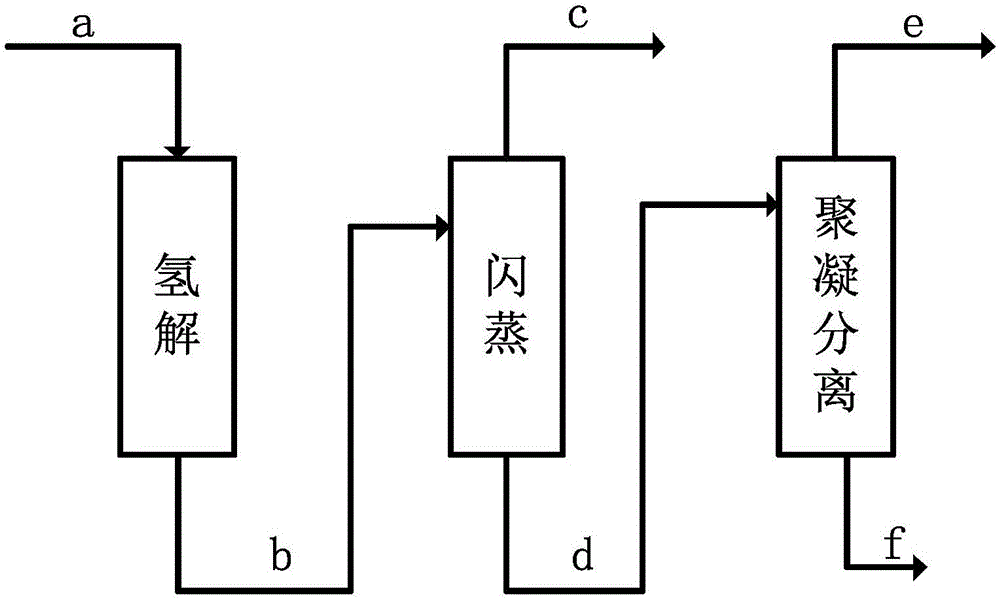

[0035] Such as figure 1 As shown, the 100mL catalyst prepared above was loaded into a fixed bed reactor with a pressure of 3Mpa and a space velocity of 35h -1, under the condition of 200°C, the COD content of stream a (source: bottom liquid after TBA cracking by-product of PO plant of Wanhua Chemical Group Co., Ltd., pH=5.3, T=126°C) is 93,400 ppm, of which 1.95wt% of alcohols, 0.92wt% o...

Embodiment 2

[0037] Weigh 1.69g of ruthenium nitrate and dissolve it in 1L of water, add 5.0g of niobium pentoxide and 175.1g of titanium dioxide, stir continuously for 20min, add sodium hydroxide to adjust the pH to 9, heat to 60°C and stir continuously for 4h, wash the slurry by centrifugation for 3 times, Dry at 110°C for 10h, roast at 400°C for 5h, and then use a mixed gas of 40v% hydrogen and 60v% nitrogen (space velocity 80h -1 ) was reduced and activated at 400°C for 12h to prepare a hydrogenolysis catalyst containing 0.3wt% ruthenium, wherein the weight ratio of Nb:Ti was 1:30.

[0038] Fill the 100mL catalyst prepared above into a fixed-bed reactor with a pressure of 2.0Mpa and a space velocity of 20h -1 , under the condition of 150°C, the COD content of stream a (source: bottom liquid after TBA pyrolysis by-product of PO plant of Wanhua Chemical Group Co., Ltd., pH=5.7, T=134°C) is 35,700PPm, of which 0.81wt% of alcohols, 0.35wt% of ethers, 0.42wt% of esters, 0.05wt% of aldehyde...

Embodiment 3

[0040] Weigh 3.93g of ruthenium nitrate and dissolve it in 1L of water, add 10.0g of niobium pentoxide and 116.7g of titanium dioxide, stir continuously for 20min, add sodium hydroxide to adjust the pH to 9, heat to 60°C and stir continuously for 4h, wash the slurry by centrifugation for 3 times, Dry at 110°C for 10h, roast at 400°C for 5h, and then use a mixed gas of 40v% hydrogen and 60v% nitrogen (with a space velocity of 120h -1 ) was reductively activated at 400°C for 17h to prepare a hydrogenolysis catalyst containing 0.97wt% ruthenium, wherein the weight ratio of Nb:Ti was 1:10.

[0041] Pack the 100mL catalyst prepared above into a fixed bed reactor with a pressure of 1.1Mpa and a space velocity of 50h -1 , under the condition of 175°C, the COD content of stream a (source: bottom liquid after TBA cracking by-product of PO plant of Wanhua Chemical Group Co., Ltd., pH=6.4, T=123°C) is 61,700PPm, of which 1.17wt% of alcohols, 0.63wt% of ethers, 0.74wt% of esters, 0.05wt%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com