Preparation method of lithium titanium phosphate anode material

A negative electrode material, lithium titanium phosphate technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor electrochemical performance and high production cost, and achieve stable quality, improved conductivity, and simple and easy process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

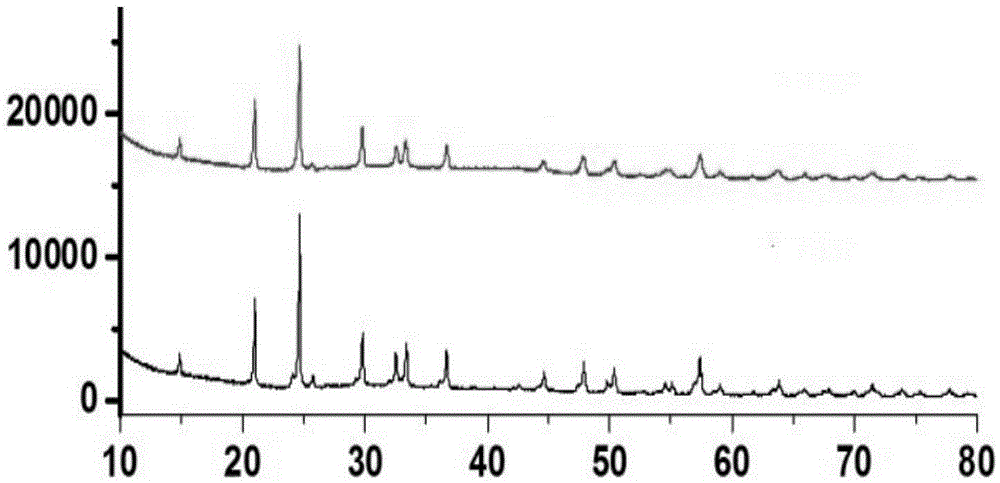

Image

Examples

Embodiment 1

[0030] Put 24.6 kg (236.7 mol) of lithium dihydrogen phosphate, 51.5 kg (445 mol) of ammonium dihydrogen phosphate, 36.8 kg (453.8 mol) of titanium dioxide, and 7.12 kg of beta cyclodextrin in a ball mill, and then add 180 kg of deionized water for Ball milling, ball milling time is 4 hours, makes dispersion mixture (solid content is 40%); Then with diaphragm pump, dispersion mixture is squeezed into the mixing tank of sand mill and carries out superfine grinding, high-speed sand milling 4h, makes the material The particle size is controlled between 500-800nm to prepare slurry. (calculated according to the amount of lithium source, titanium source and phosphorus source, the theoretical production amount of titanium lithium phosphate is 227.25mol, 88.14Kg.)

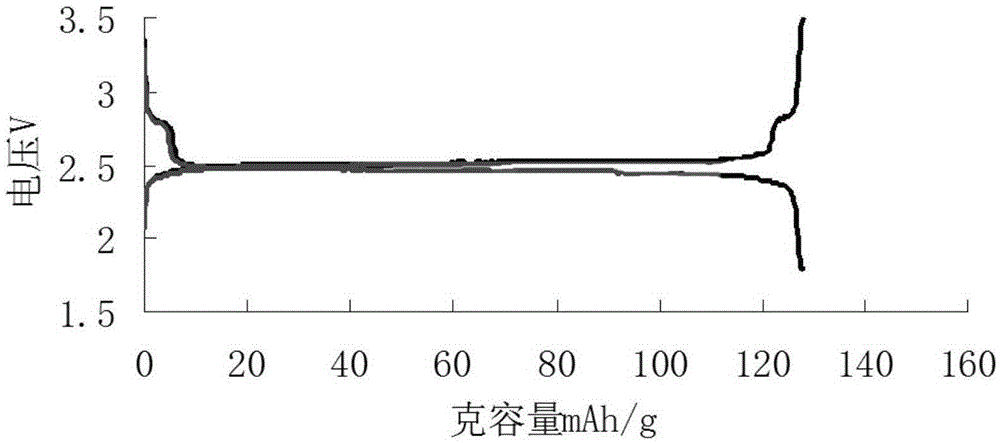

[0031] The resulting slurry was placed in a spray dryer for spray granulation, keeping the inlet temperature at 200-250° C. and the outlet temperature at 100° C. to obtain 108 kg of the initial precursor. Then 108 kg of...

Embodiment 2

[0037] 9.90 kilograms (233.7mol) of lithium hydroxide, 8.72 kilograms (75.6mol, diluted with 20 kilograms of deionized water before mixing), 70.04 kilograms of ammonium dihydrogen phosphate (605.12mol ), 36.8 kilograms (453.8mol) of titanium dioxide, and 8 kilograms of maltodextrin are placed in a ball mill, and then 175 kilograms of deionized water are added to carry out ball milling. The ball milling time is 4 hours to make a dispersion mixture (solid content is 40%). Then use a diaphragm pump to pump the dispersed mixture into the sand mill mixing tank of the sand mill for ultra-fine grinding, high-speed grinding for 4 hours, so that the particle size of the material is between 500-800nm, and the slurry is obtained.

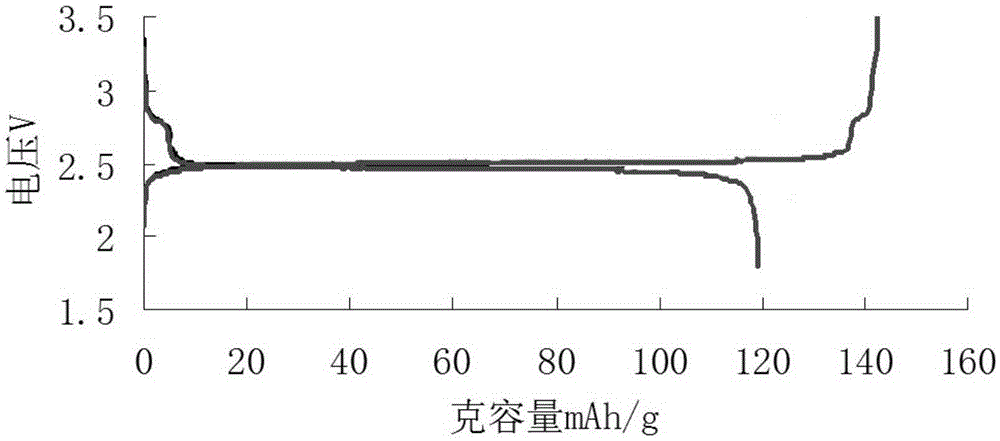

[0038]The resulting slurry was placed in a spray dryer for spray granulation, keeping the inlet temperature at 200-250° C. and the outlet temperature at 100° C. to obtain 108 kg of the initial precursor. Then, 108 kg of the initial precursor and 10 kg of gluco...

Embodiment 3

[0043] Put 24.8 kg (238.3 mol) of lithium dihydrogen phosphate, 51.2 kg (442.5 mol) of ammonium dihydrogen phosphate, 36.8 kg (453.8 mol) of titanium dioxide, 3Kg of beta-cyclodextrin, 1Kg of phenolic resin and 0.587Kg of carbon black in a ball mill , then add 121.5 kilograms of deionized water and carry out ball milling, and the ball milling time is 10 hours to make a dispersion mixture (solid content is 50%); then the dispersion mixture is squeezed into the mixing tank of the sand mill with a diaphragm pump and carried out ultrafine grinding , high-speed sanding for 1 hour, so that the particle size of the material is controlled between 500-800nm, and the slurry is prepared. (calculated based on the amount of lithium source, titanium source and phosphorus source, the theoretical production amount of titanium lithium phosphate is 226.9mol, 88.0Kg.)

[0044] The resulting slurry was placed in a spray dryer for spray granulation, keeping the inlet temperature at 370-400° C. and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com