Anti-wall-sticking efficient vacuum concentration device and application thereof

A technology of concentration device and anti-sticking wall, which is applied in the field of concentration and can solve the problems of unfavorable maintenance and high equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

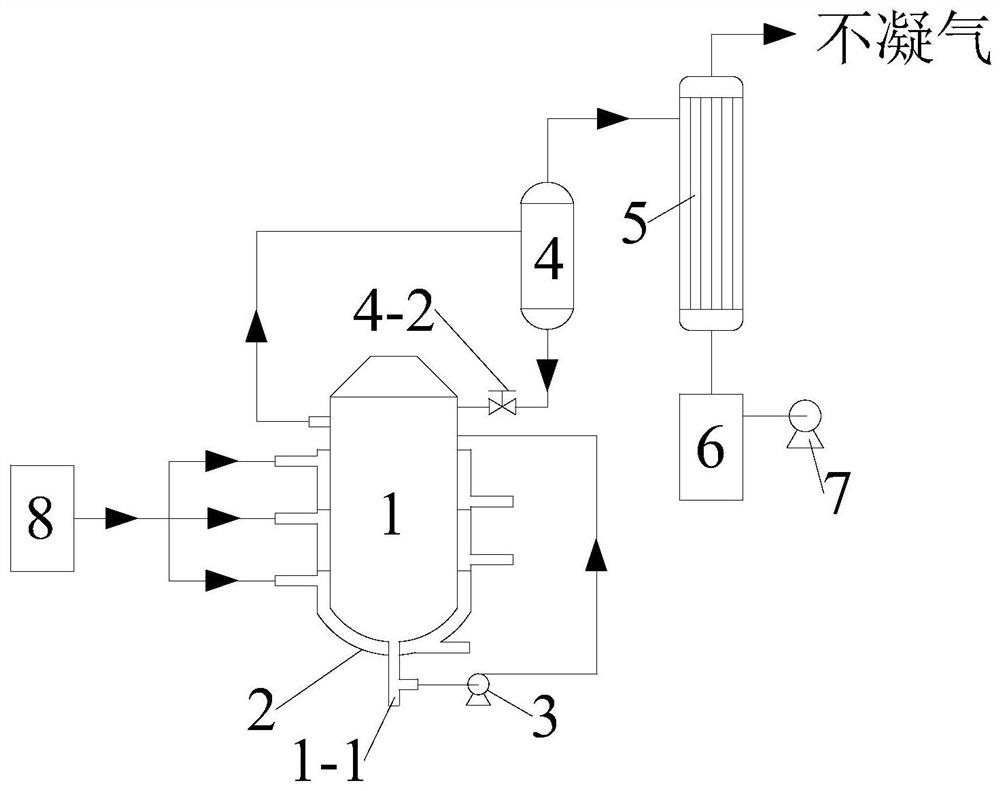

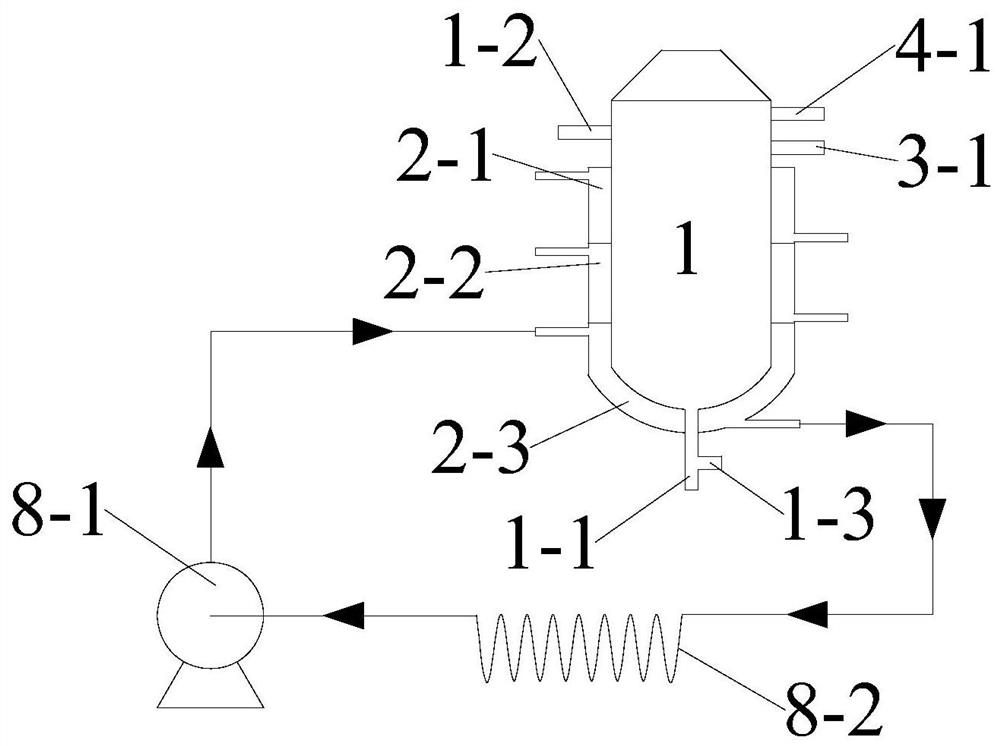

[0076] This embodiment provides an anti-adhesive wall high-efficiency decompression concentration device, which includes an evaporation chamber 1, a circulation pump 3, a gas-liquid separator 4, a condenser 5, and a liquid collector 6 , a vacuum pump 7 and a gas heat source supply device 8 .

[0077] The circulation delivery pump 3 is used to circulate the liquid to be concentrated from the bottom of the evaporation chamber 1 to the circulation liquid inlet 3-1 at the top of the evaporation chamber 1 .

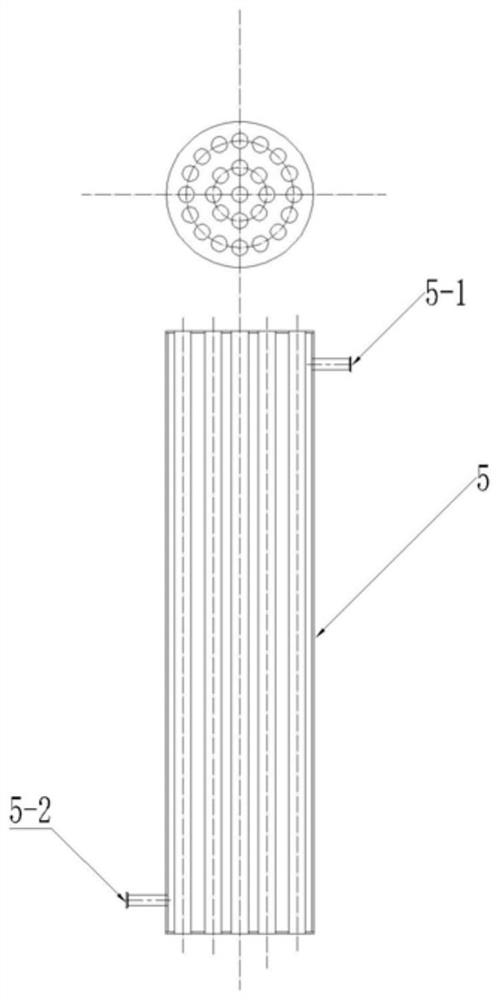

[0078] The evaporation chamber 1 is connected with the gas-liquid separator 4 through a steam pipeline 1-2, and the liquid outlet of the gas-liquid separator 4 is connected with the reflux liquid inlet 4-1 at the top of the evaporation chamber 1 through a return pipe, and the gas-liquid separator 4 The gas outlet is connected with the condenser 5.

[0079] The condensate outlet of the condenser 5 is connected to the liquid collector 6; the side wall of the liquid collector 6 ...

Embodiment 2

[0097] This embodiment provides an anti-adhesive wall high-efficiency decompression concentration device, which includes an evaporation chamber 1, a circulation pump 3, a gas-liquid separator 4, a condenser 5, and a liquid collector 6 , a vacuum pump 7 and a liquid heat source supply device 8; the circulation delivery pump 3 is used to circulate the liquid to be concentrated flowing out of the bottom of the evaporation chamber 1 to the circulating liquid inlet 3-1 at the top of the evaporation chamber 1.

[0098] The evaporation chamber 1 is connected with the gas-liquid separator 4 through a steam pipeline 1-2, and the liquid outlet of the gas-liquid separator 4 is connected with the reflux liquid inlet 4-1 at the top of the evaporation chamber 1 through a return pipe, and the gas-liquid separator 4 The gas outlet is connected with the condenser 5.

[0099] The condensate outlet of the condenser 5 is connected to the liquid collector 6; the side wall of the liquid collector 6...

Embodiment 3

[0114] This embodiment provides an anti-adhesive wall high-efficiency decompression concentration device, which includes an evaporation chamber 1, a circulation pump 3, a gas-liquid separator 4, a condenser 5, and a liquid collector 6 , a vacuum pump 7 and a gas heat source supply device 8 .

[0115] The circulation delivery pump 3 is used to circulate the liquid to be concentrated from the bottom of the evaporation chamber 1 to the circulation liquid inlet 3-1 at the top of the evaporation chamber 1 .

[0116] The evaporation chamber 1 is connected with the gas-liquid separator 4 through a steam pipeline 1-2, and the liquid outlet of the gas-liquid separator 4 is connected with the reflux liquid inlet 4-1 at the top of the evaporation chamber 1 through a return pipe, and the gas-liquid separator 4 The gas outlet is connected with the condenser 5.

[0117] The condensate outlet of the condenser 5 is connected to the liquid collector 6; the side wall of the liquid collector 6 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Heat transfer area | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com