An automatic screw-in high-pressure water-breaking coal punching method

A high-pressure water punching technology, which is applied in earthwork drilling, gas discharge, safety devices, etc., can solve the problems of shallow drilling depth, large gun head caliber, and heavy equipment, so as to reduce the generation of soft coal coal cushion, The effect of improving punching efficiency and facilitating disassembly and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

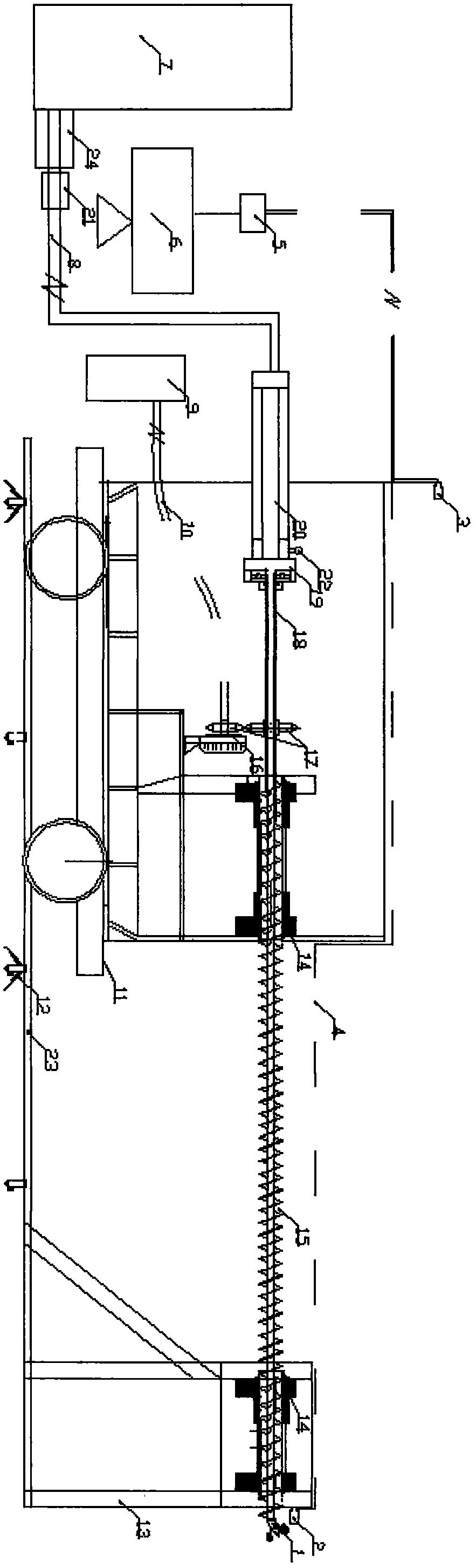

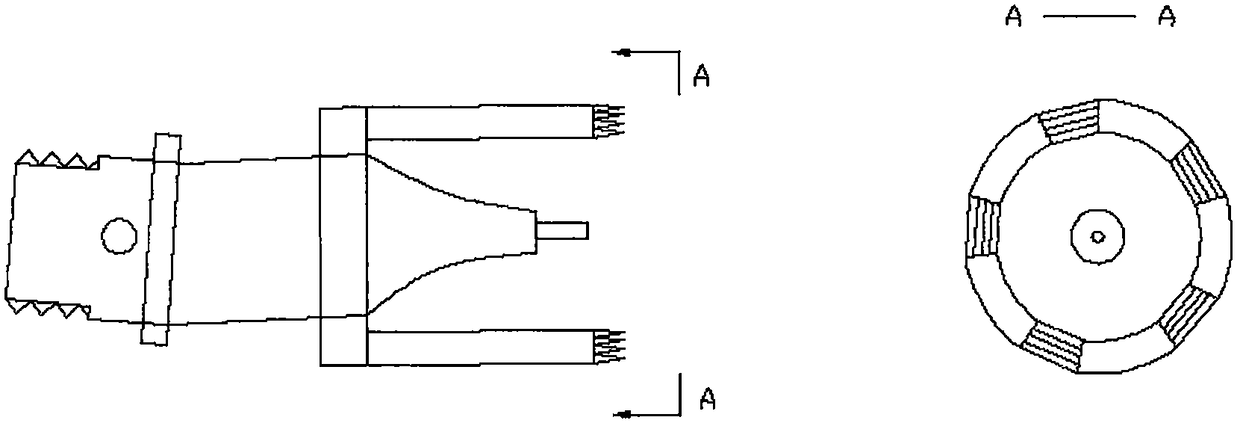

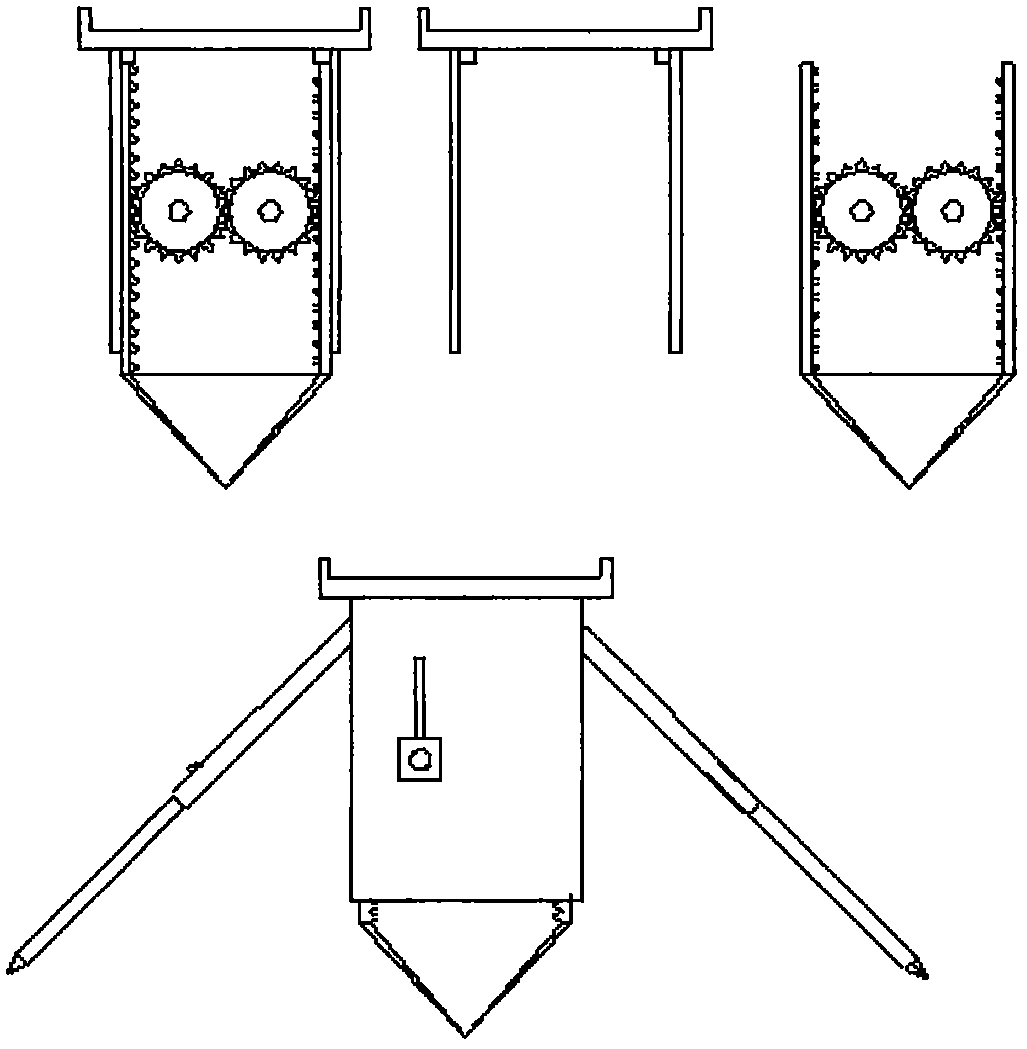

[0015] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

[0016] An automatic screw-in high-pressure water coal breaking and punching device, see attached Figure 1-5 , consisting of eccentric gun head 1, front explosion-proof waterproof camera 2, rear explosion-proof waterproof camera 3, data transmission line 4, explosion-proof video converter 5, explosion-proof display computer 6, water tank 7, high-pressure water pipe 8, hydraulic pump station 9, high-pressure oil pipe 10. Four-wheel locomotive 11, trident fixed part 12, screw-in buckle fixed bracket 13, screw-in buckle 14, screw-in screw hollow tube 15, hydraulic motor 16, transmission gear 17, rotating water supply pipe 18, rotary sleeve 19, fixed Water supply pipe 20, flow meter 21, pressure gauge 22, track 23, plunger water pump 24 form.

[0017] Automatic screw-in type high-pressure water coal breaking and punching device for punching and breaking coal: step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com