Grouting method of nontoxic low-viscosity high-strength epoxy chemical grouting material

A chemical grouting, epoxy-based technology, used in infrastructure engineering, water conservancy engineering, artificial islands, etc., can solve the problem that the initial viscosity is difficult to reach the ideal state, and achieve excellent grouting, small shrinkage, and simple ratio. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A grouting method of a non-toxic, low-viscosity, high-strength epoxy-based chemical grouting material according to the present invention comprises the following steps:

[0047] 1) Clean the dirt on the surface of the crack to make the crack penetrate;

[0048] 2) Arrange the grouting holes along the direction of the cracks, and bury one-way water-stop grouting needles in the grouting holes;

[0049] 3) The surface of the crack is sealed. For non-penetrating concrete surface cracks, it is necessary to leave vent holes at the highest point of crack extension;

[0050] 4) Prepare non-toxic, low-viscosity, high-strength epoxy-based chemical grouting grout;

[0051] 5) Connect the piston-type grouting pump to grout the grout prepared in step 4. Start from the bottom grouting hole, and grout at low pressure successively from bottom to top. If the inside has been filled, the grouting can be ended, or the grout flowing out of the vent hole can also be considered as full grout...

Embodiment 2

[0055] On the basis of Example 1, when laying out the grouting holes described in step 2, the concrete cracks should be drilled across the cracks as much as possible, and for the structural joints that can accurately grasp the direction of the cracks, the gap drilling should be used, and the distance between the grouting holes depends on the width of the cracks. Generally, 30cm±10cm is used, and a one-way water-stop grouting needle is buried in the grouting hole.

[0056] The cross-fracture drilling is arranged on the principle of the shallowest hole depth and the most conducive to the spread of slurry. It can be arranged on the same side or both sides of the crack according to the occurrence of the crack, and the bottom should be densely spaced, regardless of the same side or both sides , the hole position intersecting with the crack surface must be distributed in a plum blossom pattern on the crack surface, the distance between the drilled holes across the crack should be wit...

Embodiment 3

[0059] On the basis of Example 1, the sealing treatment of the surface of the crack described in step 3 can be filled with slotted epoxy mortar, or can be sealed by surface sticking.

[0060] The operation steps of slotted epoxy mortar filling method are as follows:

[0061] 1) Dig a U-shaped groove along the direction of the crack, the groove width is 5cm, the groove depth is 3cm, and extend more than 10cm to both ends of the crack;

[0062] 2) Use high-pressure clean air to clean the grooved part, and use a wire brush to remove loose particles;

[0063] 3) Brush the epoxy-based interface agent on the inner surface of the clean tank to ensure the bonding force between the filling material and the concrete;

[0064] 4) After the interface agent reaches the initial setting state (touch the surface with your fingers without leaving marks), fill the prepared epoxy cement material evenly into the groove, and do a good job of compacting and smoothing the surface.

[0065] The sur...

PUM

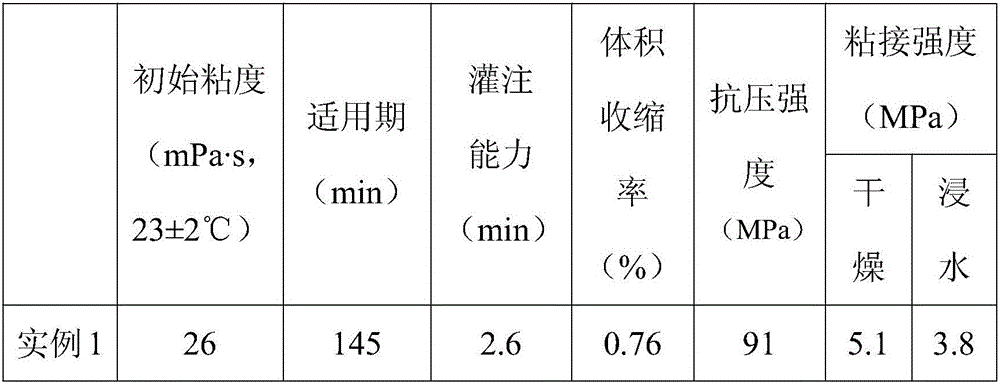

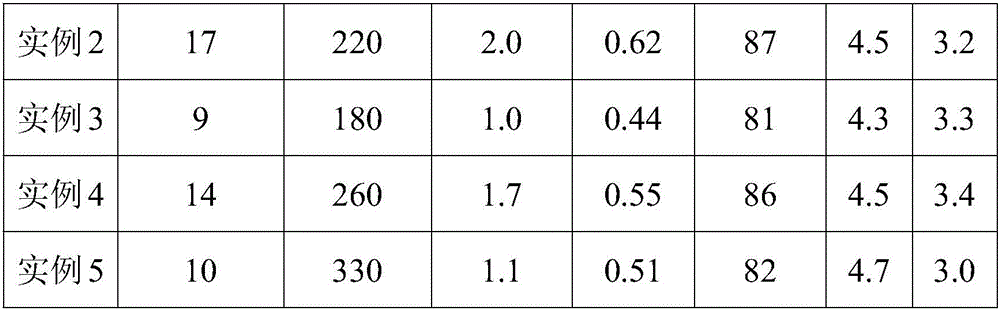

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Initial viscosity | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com