6061 aluminum alloy doped with rare earth element yttrium and preparation method of 6061 aluminum alloy

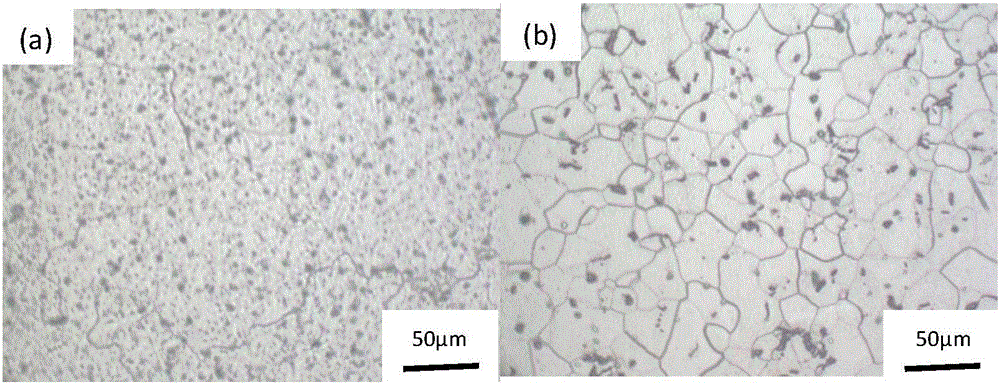

A rare earth element and aluminum alloy technology, applied in the field of 6061 aluminum alloy doped with rare earth element yttrium and its preparation, can solve the problems of 6061 aluminum alloy whose comprehensive mechanical properties cannot meet the requirements, deformation, etc., and achieve the improvement of microstructure shape and size , Improve the effect of strength and plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1: Preparation of 6061 aluminum alloy rod without Y doping.

[0024] The 6061 aluminum alloy ingot was placed in a resistance furnace, kept at 570° C. for 7 hours, and homogenized to obtain a homogenized aluminum alloy ingot.

[0025] Heat the above-mentioned homogenized aluminum alloy ingot to 450°C, extrude a rod of the required size with an extruder, and quickly straighten, cut, and air-cool.

[0026] Firstly, the above-mentioned bar is kept at 540°C for 4 hours for solution treatment, then quenched in water at room temperature for 3 minutes, and the quenching transfer time is controlled not to exceed 10 seconds, and finally kept at 180°C for 8 hours for aging treatment. A 6061 aluminum alloy rod without Y doping can be obtained.

Embodiment 2

[0027] Example 2: Prepare a 6061 aluminum alloy rod material doped with 0.4% Y.

[0028] The 6061 aluminum alloy is placed in a melting furnace, slowly heated to 760°C and kept at a constant temperature. After being completely melted, Al-10Y alloy is added to the molten aluminum until the weight of yttrium accounts for 0.4% of the total weight. Use a bell jar to press the intermediate alloy into the aluminum melt, and use graphite rods to stir continuously to make the yttrium evenly distributed. After the master alloy is completely melted, lower the melt temperature to 730°C and keep the temperature constant, add DSG deslagging and degassing agent to carry out slag and degassing treatment. After the slag and gas removal are completed, the temperature of the melt is lowered to 700°C and kept constant, and after standing for 5 minutes, it is poured into a metal mold preheated to 200°C to obtain an aluminum-yttrium alloy ingot.

[0029] The above-mentioned aluminum-yttrium allo...

Embodiment 3

[0032] Example 3: Preparation of 6061 aluminum alloy plate material doped with 0.4% Y.

[0033] Put the 6061 aluminum alloy in the melting furnace, slowly heat it to 780°C and keep the temperature constant. After being completely melted, Al-10Y alloy is added to the molten aluminum until the weight of yttrium accounts for 0.4% of the total weight. Use a bell jar to press the intermediate alloy into the aluminum melt, and use graphite rods to stir continuously to make the yttrium evenly distributed. After the master alloy is completely melted, lower the melt temperature to 740°C and keep the temperature constant, add DSG deslagging and degassing agent to carry out slag and degassing treatment. After the slag and gas removal are completed, the temperature of the melt is lowered to 720°C and kept constant, and after standing for 10 minutes, it is poured into a metal mold preheated to 200°C to obtain an aluminum-yttrium alloy ingot.

[0034] The above-mentioned aluminum-yttrium ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com