Preparation method of polyether-grafted chitosan derivative crude oil desalting demulsifier

A technology of chitosan derivatives and demulsifiers, which is applied in the direction of dehydration/demulsification by chemical methods, can solve the problems of metal cation removal and weak binding ability, and achieve the effect of wide sources and good use safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

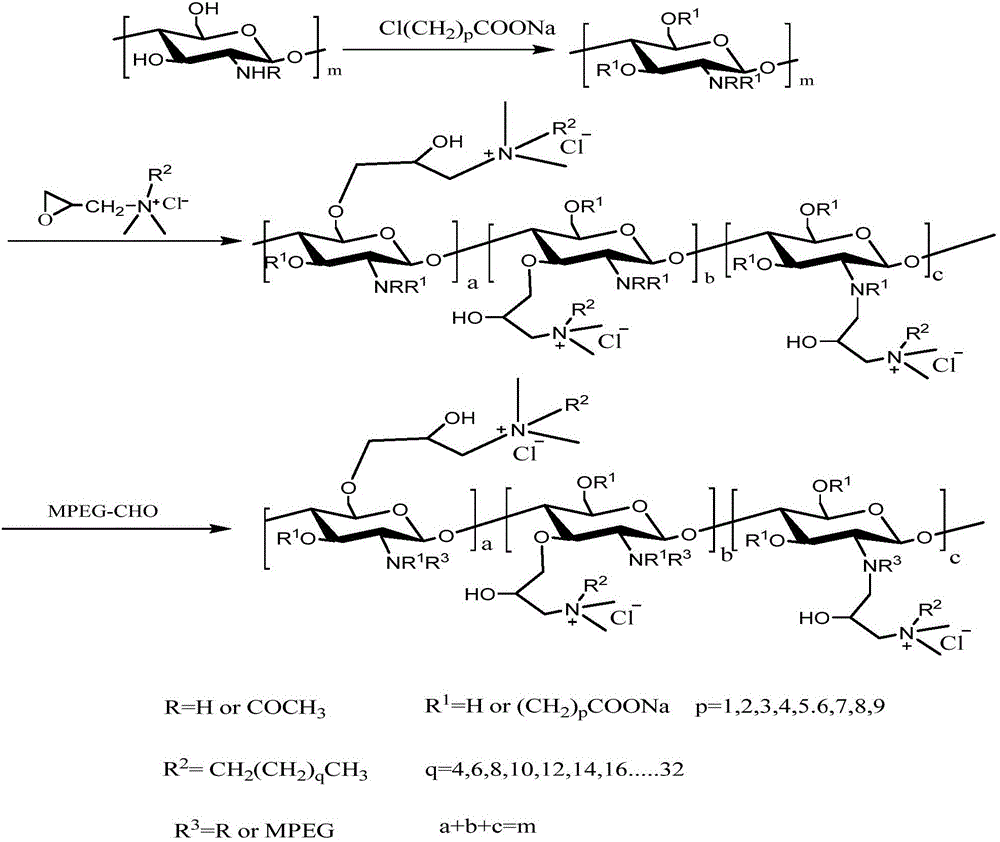

[0044] A kind of preparation of polyether grafted chitosan derivative crude oil desalination demulsifier, concrete steps are as follows:

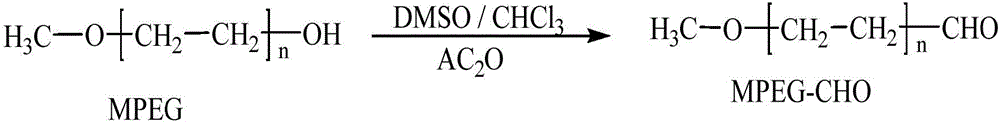

[0045] (1) Formylation modification of polyethylene glycol monomethyl ether terminal hydroxyl group: take 1.75g (5mmol) polyethylene glycol monomethyl ether (Mn=350) and dissolve it in 30mL of anhydrous dimethyl sulfoxide and 2mL of chloroform In the mixed solution, keep the reaction under nitrogen atmosphere, add 5.1mL (50mmol) acetic anhydride solution under constant stirring at room temperature, heat to 15°C, and react at constant temperature for 5h. After the reaction was completed, the reaction liquid was added to 400 mL of anhydrous ether, and the obtained precipitate was dissolved in chloroform and then recrystallized with ether solution (repeat this step once), and then vacuum-dried at room temperature for 24 hours to obtain the hydroformylated polyethylene glycol monomethyl ether .

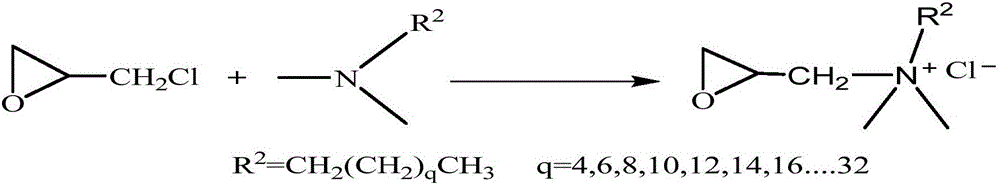

[0046] (2) Preparation of glycidyl dimethyl d...

Embodiment 2

[0051] A kind of preparation of polyether grafted chitosan derivative crude oil desalination demulsifier, concrete steps are as follows:

[0052] (1) Formylation modification of polyethylene glycol monomethyl ether terminal hydroxyl group: take polyethylene glycol monomethyl ether (Mn=750) 3.75g (5mmol) and dissolve in 30mL of anhydrous dimethyl sulfoxide and 2mL of chloroform In the mixed solution, keep the reaction under nitrogen atmosphere, add 5.1mL (50mmol) acetic anhydride solution under constant stirring at room temperature, heat to 20°C, and react at constant temperature for 7h. After the reaction was completed, the reaction liquid was added to 400 mL of anhydrous ether, and the obtained precipitate was dissolved in chloroform and then recrystallized with ether solution (repeat this step once), and then vacuum-dried at room temperature for 24 hours to obtain the hydroformylated polyethylene glycol monomethyl ether .

[0053] (2) Preparation of glycidyl dimethyltetrade...

Embodiment 3

[0058] A kind of preparation of polyether grafted chitosan derivative crude oil desalination demulsifier, concrete steps are as follows:

[0059] (1) Formylation modification of polyethylene glycol monomethyl ether terminal hydroxyl group: take polyethylene glycol monomethyl ether (Mn=1000) 5g (5mmol) and dissolve in 30mL of anhydrous dimethyl sulfoxide and 2mL of chloroform In the solution, keep the reaction under nitrogen atmosphere, add 5.1mL (50mmol) acetic anhydride solution under constant stirring at room temperature, raise the temperature to 30°C, and keep the reaction time at constant temperature for 9h. After the reaction was completed, the reaction liquid was added to 400 mL of anhydrous ether, and the obtained precipitate was dissolved in chloroform and then recrystallized with ether solution (repeat this step once), and then vacuum-dried at room temperature for 24 hours to obtain the hydroformylated polyethylene glycol monomethyl ether .

[0060] (2) Preparation o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com