Epoxysuccinic acid polymer and preparation method thereof and system and method for treating water by combining epoxysuccinic acid polymer, magnetic field and static electricity

A technology of epoxy succinic acid and polymer, applied in the fields of magnetic field/electric field water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as no application value and ineffectiveness , to achieve the effect of reducing the dosage of chemicals, improving performance and reducing chemical pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

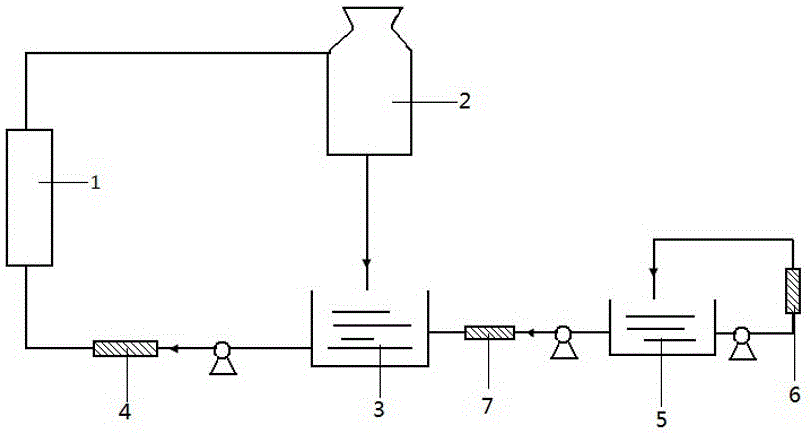

Image

Examples

Embodiment 1

[0030] (1) In a four-neck flask equipped with a reflux condenser, a thermometer and a dropping funnel, add 18.375 g of maleic anhydride and 40 mL of deionized water, and dissolve under magnetic stirring. Add 50 mL of 10 mol / L NaOH solution dropwise to the solution, at this time maleic anhydride is hydrolyzed to sodium maleate. During the dropwise addition, the temperature rises, and the temperature is controlled below 55°C. After the dropwise addition, the temperature was raised to 55 °C, 0.46 g of sodium molybdate catalyst was added, and then 10 mL of 30% hydrogen peroxide was slowly added dropwise as an initiator, and the dropping time was about 0.5 h. After the dropwise addition, the temperature was raised to 70°C, and the epoxidation was carried out for 0.5 h.

[0031] (2) Add IA (itaconic acid), AMPS (2-acrylamide-2-methylsulfonic acid), sodium bisulfite, ammonium ferrous sulfate, isopropanol and thioglycolic acid to the solution. The mass ratio of ESA (epoxysuccinic ac...

Embodiment 2

[0047] (1) In a four-neck flask equipped with a reflux condenser, a thermometer and a dropping funnel, add 16.34 g of maleic anhydride and 40 mL of deionized water, and dissolve under magnetic stirring. 50 mL of 10 mol / L NaOH solution was added dropwise to the solution, at this time maleic anhydride was hydrolyzed into sodium maleate. During the dropwise addition, the temperature rises, and the temperature is controlled below 55°C. After the dropwise addition, the temperature was raised to 55°C, 0.41 g of sodium molybdate catalyst was added, and then 10 mL of 30% hydrogen peroxide was slowly added dropwise as an initiator, and the dropping time was about 0.5 h. After the dropwise addition was completed, the temperature was raised to 65°C, and epoxidation was carried out for 0.5 h.

[0048] (2) Add IA (itaconic acid), AMPS (2-acrylamide-2-methylsulfonic acid), sodium bisulfite, ammonium ferrous sulfate, isopropanol and thioglycolic acid to the solution. The mass ratio of ESA ...

Embodiment 3

[0064] (1) In a four-necked flask equipped with a reflux condenser, a thermometer and a dropping funnel, add 19.6 g of maleic anhydride and 40 mL of deionized water, and dissolve under magnetic stirring. 50 mL of 10 mol / L NaOH solution was added dropwise to the solution, at this time maleic anhydride was hydrolyzed into sodium maleate. During the dropwise addition, the temperature rises, and the temperature is controlled below 55°C. After the dropwise addition, the temperature was raised to 55°C, 0.49 g of sodium molybdate catalyst was added, and 10 mL of 30% hydrogen peroxide was slowly added dropwise as an initiator for about 0.5 h. After the dropwise addition, the temperature was raised to 70°C, and the epoxidation was carried out for 0.5 h.

[0065] (2) Add IA, AMPS, sodium bisulfite, ammonium ferrous sulfate, isopropanol and thioglycolic acid to the solution. The mass ratio of ESA:IA:AMPS is 1:0.2:0.3, isopropanol and thioglycolic acid are 0.5% of the total mass of mono...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com