Process method for treating 65Mn steel material through ECAE (Equal Channel Angular Extrusion)

A process method and technology of process steps, applied in the field of material processing for agricultural machinery, can solve the problems of unreachable, reduced friction and wear performance, poor toughness of surface materials, etc., and achieve improved performance, improved material structure, and improved microhardness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

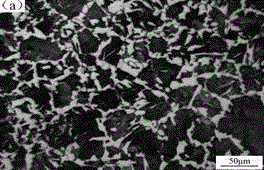

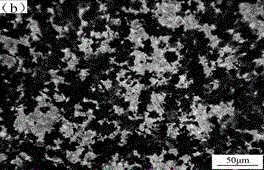

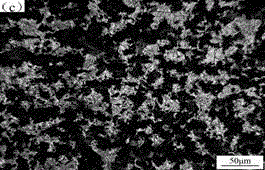

[0038] In order to make the above and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are taken as an example and described in detail below with reference to the accompanying drawings.

[0039] The processing steps of the preferred embodiment include:

[0040] Cut the 65Mn steel material into a cuboid with a size of 100 mm×9.9 mm×9.9 mm with a plasma cutting machine, chamfer the cuboid obtained after cutting, grind and polish with a grinder after chamfering, and scrub the surface with acetone , coated with a glass lubricant after scrubbing to obtain a blank;

[0041] The prepared billet was kept at 850°C for 20 minutes;

[0042] Molybdenum disulfide lubricant is coated on the inner surface of the first mold, and the first mold is placed at 600 ° C for 1 hour for preheating, wherein, such as figure 1 As shown, the first mold 1 has a vertical entry channel 11 and a horizontal extrusion chan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com