Coconut juice and preparation method thereof

A coconut milk and coconut milk technology, applied in the field of coconut milk and its preparation, can solve the problems of poor product taste, thin product taste, lag in the development of processing industry, etc., and achieve good product stability, rich product nutrition, and strong taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] The invention provides a beverage and a preparation method thereof. In the preparation method, coconut water is added to the coconut meat extract, and the drink with good stability, good taste and comprehensive nutrition is obtained after homogenization treatment.

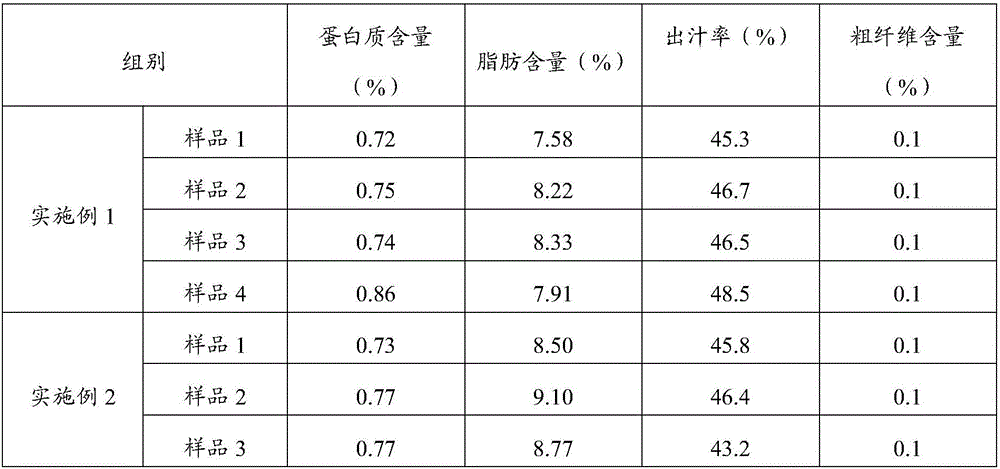

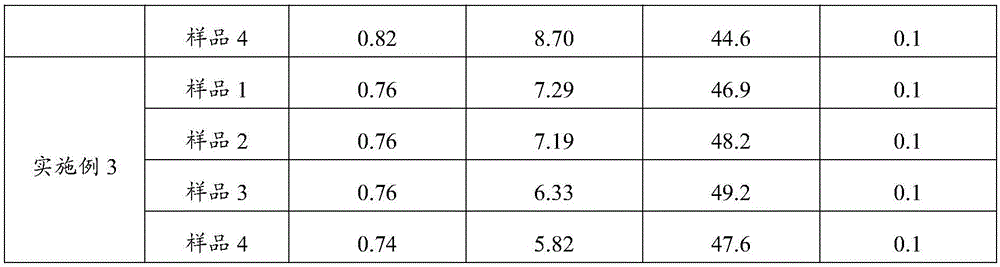

[0085] This process is to adjust the juice extraction method in the traditional coconut water processing method, improve the homogeneous conditions, use scientific fresh-keeping methods and precise filtration methods to make coconut water, and then mix it with coconut milk. The obtained coconut juice drink raw juice has a higher extraction rate of active ingredients (the juice yield is 3.4-13.9% higher, the crude fiber content of the product is increased by 117-285%, the protein content of the extract is increased by 18-26%, and the fat content is 27.6-39.6%) ), with significant difference (P<0.05). The product has a good taste and strong coconut fragrance, and the shelf life at room temperature is extended...

Embodiment 1

[0088] The preparation of embodiment 1 coconut milk

[0089] (1) Get the white coconut pulp, add water to crush and grind to obtain the pulp, and obtain the coconut meat extract (the protein content is 0.77%, and the fat content is 8.01%); in g / mL, the mass volume ratio of the white coconut pulp and water 1:2;

[0090] Broken in g / mL, the mass volume ratio of coconut white pulp to 70°C water is 1:0.5, soaked for 10min and then crushed.

[0091] Crushing means that after the primary crushing, the meat particles are ≤ 8mm, and after the secondary crushing, the meat particles are ≤ 5mm.

[0092] Grinding is, in g / mL, the mass volume ratio of coconut white pulp and 65°C water is 1:0.5, after the first grinding slurry, centrifuged and filtered at 1000rpm, the first filtrate is collected to obtain the first coconut meat extract;

[0093] Collect the first filter residue, in g / mL, add 65°C water with a mass volume ratio of 1:1 to the first filter residue, pass through the second gr...

Embodiment 2

[0108] The preparation of embodiment 2 coconut milk

[0109] (1) Get the white coconut pulp, add water to crush and grind to obtain the pulp, and obtain the coconut meat extract (the protein content is 0.77%, and the fat content is 8.77%); in g / mL, the mass volume ratio of the white coconut pulp and water is 1:2.5;

[0110] Crushed in g / mL, the mass volume ratio of coconut white pulp to 80°C water is 1:0.5, soaked for 20min and then broken.

[0111] Crushing means that after the primary crushing, the meat particles are ≤ 8mm, and after the secondary crushing, the meat particles are ≤ 5mm.

[0112] Grinding is, in g / mL, the mass volume ratio of coconut white pulp and 50°C water is 1:0.5, after the first grinding slurry, centrifuged at 3200rpm and filtered, the first filtrate is collected to obtain the first coconut meat extract;

[0113] Collect the first filter residue, in g / mL, add 50°C water with a mass volume ratio of 1:1 to the first filter residue, pass through the seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com