CdTe solar cell manufacturing method capable of reducing defect density

A technology of solar cells and cadmium telluride, which is applied in sustainable manufacturing/processing, circuits, photovoltaic power generation, etc., can solve the problems of reducing the lifetime of unbalanced carriers and reducing the performance of solar cells, so as to improve photoelectric conversion efficiency and reduce Effect of improving defect density and battery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

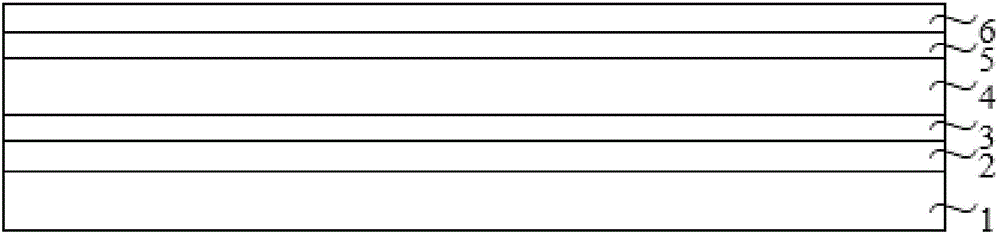

[0017] Such as figure 1 As shown, in order to compare the situation before and after the improvement of the present invention more specifically, the preparation method of the traditional cadmium telluride solar cell is introduced first. Firstly, 800nm SnO2:F thin film 2 (FTO) is deposited on the glass substrate 1 by CVD method as the transparent front electrode of the battery. Deposit a 50-500nm n-type CdS window layer 3 on the SnO2:F film 2 by vapor transport method, the deposition conditions are pressure 10-1000pa, temperature 100°C-650°C; O2 concentration 0.01%-10%, and then deposit 1-8um p-type CdTe film 4; CdCl after spraying 0.5-100um on the surface of CdTe film 4 2 solution, and then annealed in the atmosphere at 100-500°C for 30 minutes, and etched the annealed cadmium telluride battery in a solution containing 0.1-1.5% nitric acid; then deposited a buffer layer 5 on the etched CdTe surface , depositing a layer of Mo / Al / Cr metal back electrode 6 on the buffer layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com