A kind of er-se-sb nano phase change film material and its preparation method and application

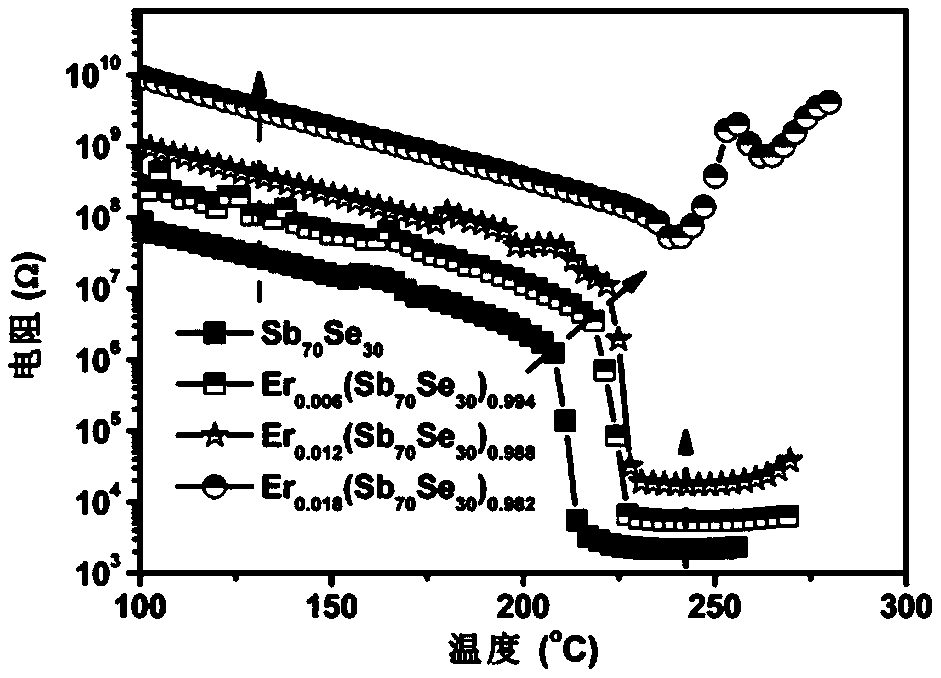

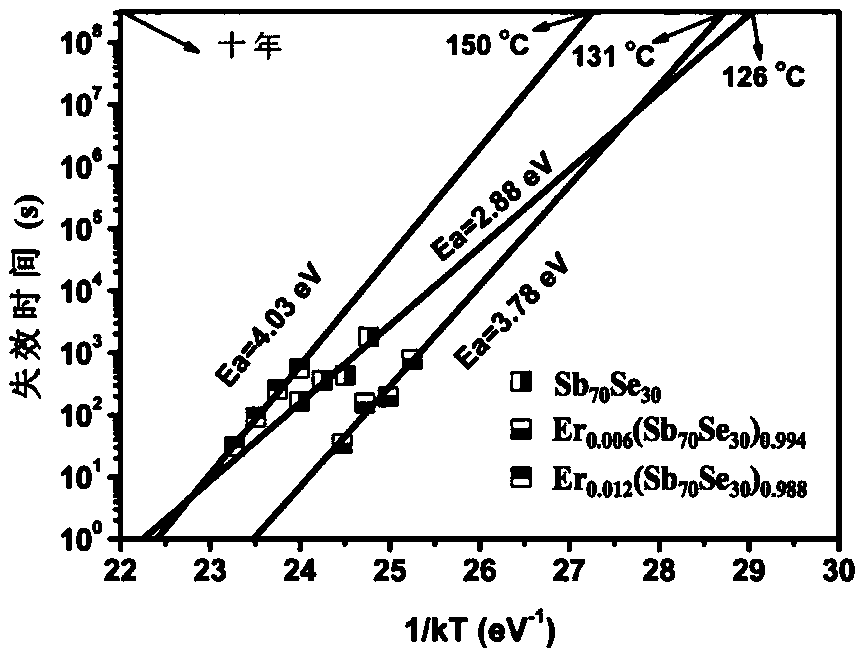

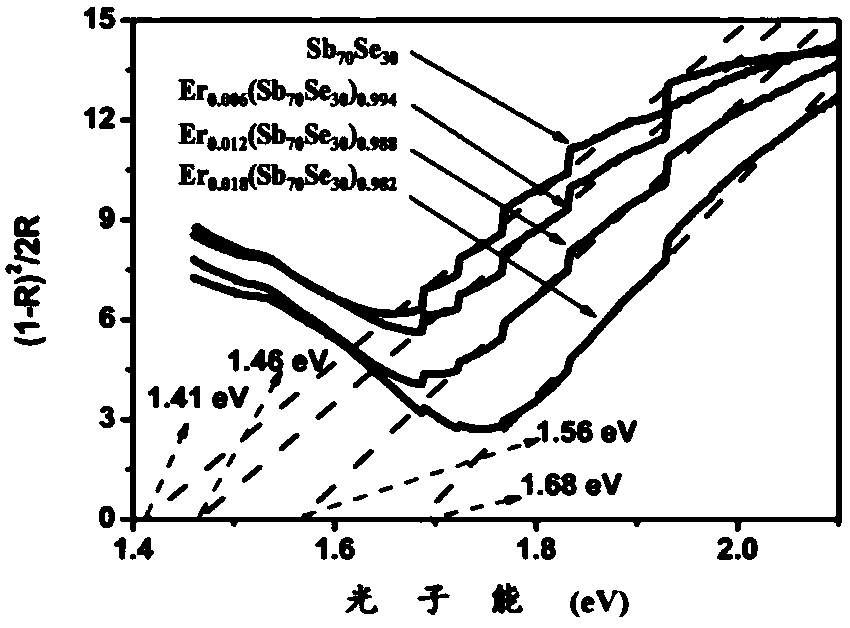

A technology of er-se-sb and thin-film materials, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve problems such as poor thermal stability, low crystallization temperature, and unsatisfactory data retention , to achieve the effects of reduced power consumption, high crystallization temperature and data retention, high crystalline and amorphous resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Preparation of Se without Er doping 30 Sb 70 Nano phase change thin film material.

[0036] 1. Clean SiO2 2 / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities;

[0037] a) Strong ultrasonic cleaning in acetone solution for 3 to 5 minutes, then rinse with deionized water;

[0038] b) Strong ultrasonic cleaning in ethanol solution for 3-5 minutes, rinse with deionized water, high-purity N 2 Blow dry the surface and back;

[0039] c) Dry the water vapor in an oven at 120°C for about 20 minutes.

[0040] 2. Preparation of Se by radio frequency sputtering method 30 Sb 70 Film preparation:

[0041] a) Install Se 30 Sb 70 Sputtering target (atomic percentage purity reaches 99.999%), and the background vacuum is evacuated to 1×10 -4 Pa;

[0042] b) Set the sputtering power to 30W;

[0043]c) Using high-purity argon (volume percent purity up to 99.999%) as the sputtering gas, setting the argon flow rate to 30 s...

Embodiment 2

[0048] Embodiment 2: preparation Er 0.006 (Se 30 Sb 70 ) 0.994 Nano phase change thin film material.

[0049] 1. Clean SiO2 2 / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities;

[0050] a) Strong ultrasonic cleaning in acetone solution for 3 to 5 minutes, then rinse with deionized water;

[0051] b) Strong ultrasonic cleaning in ethanol solution for 3-5 minutes, rinse with deionized water, high-purity N 2 Blow dry the surface and back;

[0052] c) Dry the water vapor in an oven at 120°C for about 20 minutes.

[0053] 2. Preparation of Er by RF sputtering method 0.006 (Se 30 Sb 70 ) 0.994 Film preparation:

[0054] a) Install Se 30 Sb 70 For the sputtering target, place a fan-shaped Er sheet with a thickness of 2mm, a diameter of 40mm, and an arc of 15° on Se 30 Sb 70 The surface of the target, so that the centers of the two circles coincide, and the background vacuum is evacuated to 1×10 -4 Pa, where Se 30 Sb 70 The...

Embodiment 3

[0061] Embodiment 3: preparation Er 0.012 (Se 30 Sb 70 ) 0.988 Nano phase change thin film material.

[0062] 1. Clean SiO2 2 / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities;

[0063] a) Strong ultrasonic cleaning in acetone solution for 3 to 5 minutes, then rinse with deionized water;

[0064] b) Strong ultrasonic cleaning in ethanol solution for 3-5 minutes, rinse with deionized water, high-purity N 2 Blow dry the surface and back;

[0065] c) Dry the water vapor in an oven at 120°C for about 20 minutes.

[0066] 2. Preparation of Er by RF sputtering method 0.012 (Se 30 Sb 70 ) 0.988 Film preparation:

[0067] a) Install Se 30 Sb 70 For the sputtering target, put two fan-shaped Er sheets with a thickness of 2mm, a diameter of 40mm, and an arc of 15° on Se 30 Sb 70 The surface of the target, so that the centers of the two circles coincide, and the background vacuum is evacuated to 1×10 -4 Pa, where Se 30 Sb 70 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com