Er-Se-Sb nanometer phase change film material and preparation method and application thereof

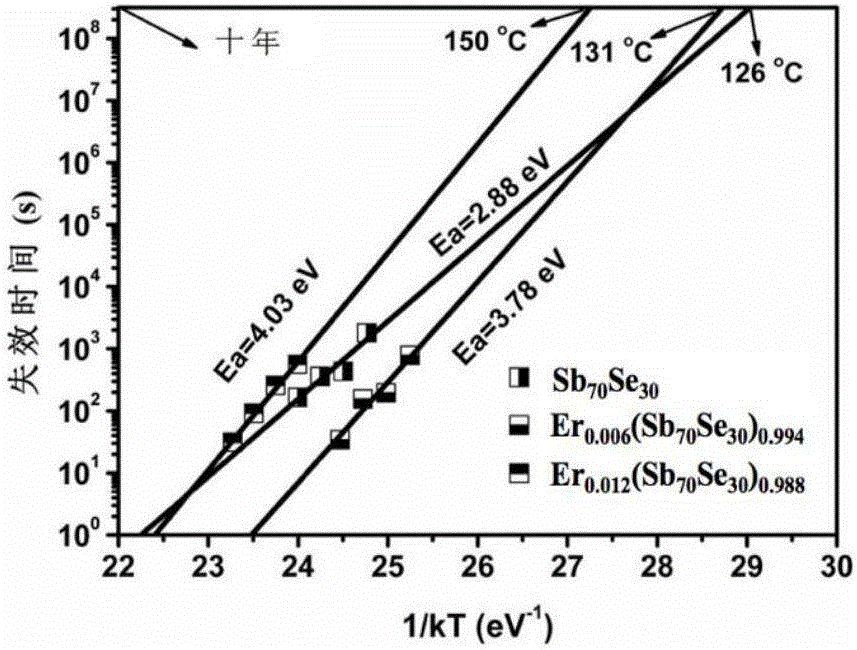

A thin film material, nanophase technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low crystallization temperature, unsatisfactory data retention, poor thermal stability, etc. Crystallization temperature and data retention, high crystalline and amorphous resistance, effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: Preparation of Se without Er doping 30 Sb 70 Nano phase change thin film material.

[0036] 1. Clean SiO2 2 / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities;

[0037] a) Strong ultrasonic cleaning in acetone solution for 3 to 5 minutes, then rinse with deionized water;

[0038] b) Strong ultrasonic cleaning in ethanol solution for 3-5 minutes, rinse with deionized water, high-purity N 2 Blow dry the surface and back;

[0039] c) Dry the water vapor in an oven at 120°C for about 20 minutes.

[0040] 2. Preparation of Se by radio frequency sputtering method 30 Sb 70 Film preparation:

[0041] a) Install Se 30 Sb 70 Sputtering target (atomic percentage purity reaches 99.999%), and the background vacuum is evacuated to 1×10 -4 Pa;

[0042] b) Set the sputtering power to 30W;

[0043]c) Using high-purity argon (volume percent purity up to 99.999%) as the sputtering gas, setting the argon flow rate to 30 s...

Embodiment 2

[0048] Embodiment 2: preparation Er 0.006 (Se 30 Sb 70 ) 0.994 Nano phase change thin film material.

[0049] 1. Clean SiO2 2 / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities;

[0050] a) Strong ultrasonic cleaning in acetone solution for 3 to 5 minutes, then rinse with deionized water;

[0051] b) Strong ultrasonic cleaning in ethanol solution for 3-5 minutes, rinse with deionized water, high-purity N 2 Blow dry the surface and back;

[0052] c) Dry the water vapor in an oven at 120°C for about 20 minutes.

[0053] 2. Preparation of Er by RF sputtering method 0.006 (Se 30 Sb 70 ) 0.994 Film preparation:

[0054] a) Install Se 30 Sb 70 For the sputtering target, place a fan-shaped Er sheet with a thickness of 2mm, a diameter of 40mm, and an arc of 15° on Se 30 Sb 70 The surface of the target, so that the centers of the two circles coincide, and the background vacuum is evacuated to 1×10 -4 Pa, where Se 30 Sb 70 The...

Embodiment 3

[0061] Embodiment 3: preparation Er 0.012 (Se 30 Sb 70 ) 0.988 Nano phase change thin film material.

[0062] 1. Clean SiO2 2 / Si(100) substrate surface and back, remove dust particles, organic and inorganic impurities;

[0063] a) Strong ultrasonic cleaning in acetone solution for 3 to 5 minutes, then rinse with deionized water;

[0064] b) Strong ultrasonic cleaning in ethanol solution for 3-5 minutes, rinse with deionized water, high-purity N 2 Blow dry the surface and back;

[0065] c) Dry the water vapor in an oven at 120°C for about 20 minutes.

[0066] 2. Preparation of Er by RF sputtering method 0.012 (Se 30 Sb 70 ) 0.988 Film preparation:

[0067] a) Install Se 30 Sb 70 For the sputtering target, put two fan-shaped Er sheets with a thickness of 2mm, a diameter of 40mm, and an arc of 15° on Se 30 Sb 70 The surface of the target, so that the centers of the two circles coincide, and the background vacuum is evacuated to 1×10 -4 Pa, where Se 30 Sb 70 Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com