Efficient heat-resisting and flame-retarding composition and preparation method thereof

A flame-retardant composition and heat-resistant technology, applied in the field of new energy and environmental protection and energy saving, can solve the problem of low heat resistance, achieve excellent flame-retardant effect, easy processing, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

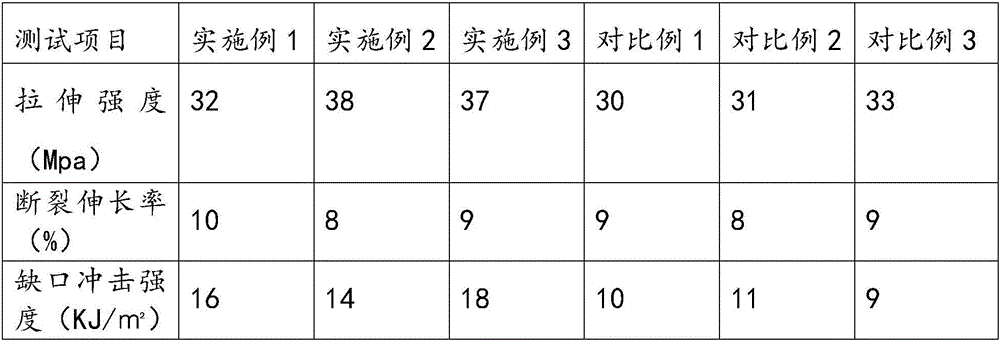

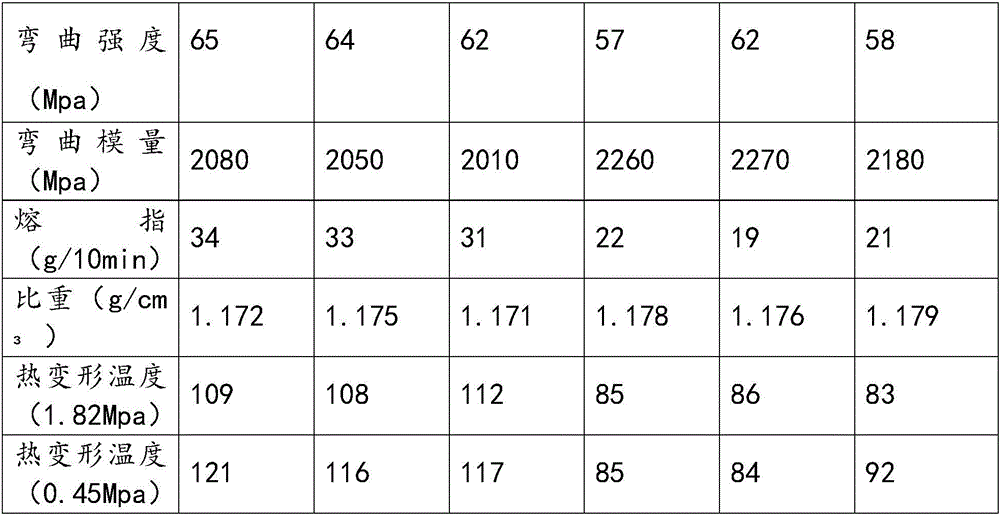

Embodiment 1

[0019] A high-efficiency and environmentally friendly high-efficiency heat-resistant flame-retardant composition, the acrylonitrile-styrene-acrylic acid terpolymer ASA55 parts, the melamine cyanurate 30 parts, the flame-retardant synergist 1 part, heat-resistant modified 15 parts of active agent, 0.1 part of zinc stearate, 0.1 part of polyvinyl butyral, 1 part of thiodipropionate diester, 6 parts of benzotriazoles; wherein, the flame retardant synergist is composed of A compound composed of magnesium hydroxide, wollastonite powder and ultra-high molecular weight polysiloxane. The ultra-high molecular weight polysiloxane is vinyl polysiloxane, the molecular weight of the vinyl polysiloxane is ≥30,000, and its viscosity is ≥500 mPa·s at a temperature of 25°C. The heat-resistant modifier is N-isopropylmaleimide, N-cyclohexylmaleimide, poly(N-n-octadecylmaleimide), N-phenylmaleimide One or more mixtures of imide and poly(N-n-butylmaleimide); the zinc stearate is vinylbisstearamid...

Embodiment 2

[0021] A high-efficiency and environmentally friendly high-efficiency heat-resistant flame-retardant composition, the acrylonitrile-styrene-acrylic acid terpolymer ASA60 parts, the melamine cyanurate 35 parts, the flame-retardant synergist 5 parts, heat-resistant modified 17 parts of active agent, 0.5 part of zinc stearate, 0.6 part of polyvinyl butyral, 1.5 parts of thiodipropionate diester, 8 parts of benzotriazoles, and the remaining components and proportioning are the same as in Example 1 The same as disclosed in .

Embodiment 3

[0023] An efficient and environmentally friendly high-efficiency heat-resistant and flame-retardant composition, including the following components by weight: 70 parts of acrylonitrile-styrene-acrylic acid terpolymer ASA, 45 parts of melamine cyanurate, 10 parts of flame-retardant synergist, 20 parts of heat-resistant modifier, 01 parts of zinc stearate, 1 part of polyvinyl butyral, 2 parts of thiodipropionate diester, and 10 parts of benzotriazoles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com