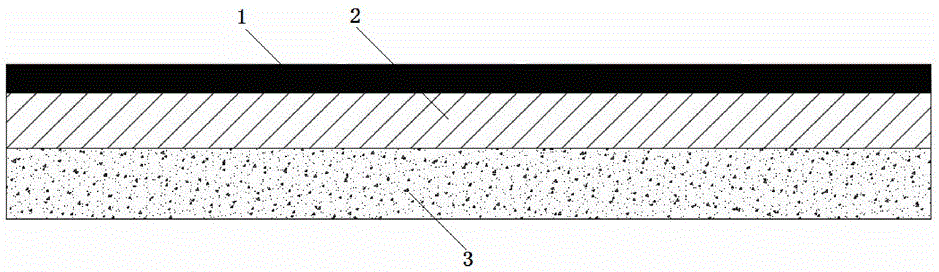

Scratching-resistant, wear-resistant and aging-resistant composite spraying film non-woven fabric material

A coating non-woven fabric, anti-aging technology, applied in the field of composite materials, can solve the problems of lower mechanical properties of materials, high price, low resin volume content, etc., and achieve improved surface quality, high surface hardness, and good thermal stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1: Copolymerized polypropylene coated non-woven fabric

[0049] (1) Preparation of color masterbatch

[0050] Choose 70 parts of titanium dioxide,

[0051] 5 parts of low molecular weight polyethylene wax,

[0052] Zinc stearate 0.5 parts,

[0053] EBS 0.5 share,

[0054] 0.5 parts of maleic anhydride grafted PP,

[0055] 0.5 part of silane coupling agent,

[0056] Copolymerized polypropylene 23 parts

[0057] Then pour other materials except the coupling agent into the high-speed mixer, mix at a low speed for 5 minutes, then add the coupling agent, mix at a high speed for 10 minutes, send the mixed materials into the extruder for extrusion, and cool Masterbatch is made after drying.

[0058] (2) Accurate weighing

[0059] Copolymer polypropylene 100

[0060] masterbatch 5

[0061] Antioxidant 1010 0.4

[0063] UV 327 0.3

[0064] Then put it into a high mixer and mix it at a low speed for 3 minutes, then take it out and p...

Embodiment 2

[0066] Embodiment 2: Homopolypropylene coating non-woven fabric

[0067](1) Preparation of color masterbatch

[0068] Select 50 parts of titanium dioxide,

[0069] 8 parts of low molecular weight polyethylene wax,

[0071] 1 copy of EBS,

[0072] 0.5 parts of maleic anhydride grafted PP,

[0073] 0.5 part of silane coupling agent,

[0074] Copolymerized polypropylene 40 parts

[0075] Then pour other materials except the coupling agent into the high-speed mixer, mix at a low speed for 5 minutes, then add the coupling agent, mix at a high speed for 10 minutes, send the mixed materials into the extruder for extrusion, and cool Masterbatch is made after drying.

[0076] (2) Accurate weighing

[0077] Copolymer polypropylene 100

[0078] masterbatch 6

[0079] Antioxidant 1010 0.6

[0080] Zinc stearate 0.2

[0081] UV 327 0.4

[0082] Then put it into a high mixer and mix it at a low speed for 3 minutes, then take it out and put it into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com