Solar back plate with high barrier property

A solar back sheet, high-barrier technology, applied in the field of solar back sheets, can solve the problems of reflectivity, anti-aging performance, poor water resistance, limited water vapor and oxygen barrier properties, and solar back sheet barrier effects, etc. Aging performance, reduced water vapor and oxygen transmission rates, and outstanding protective effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

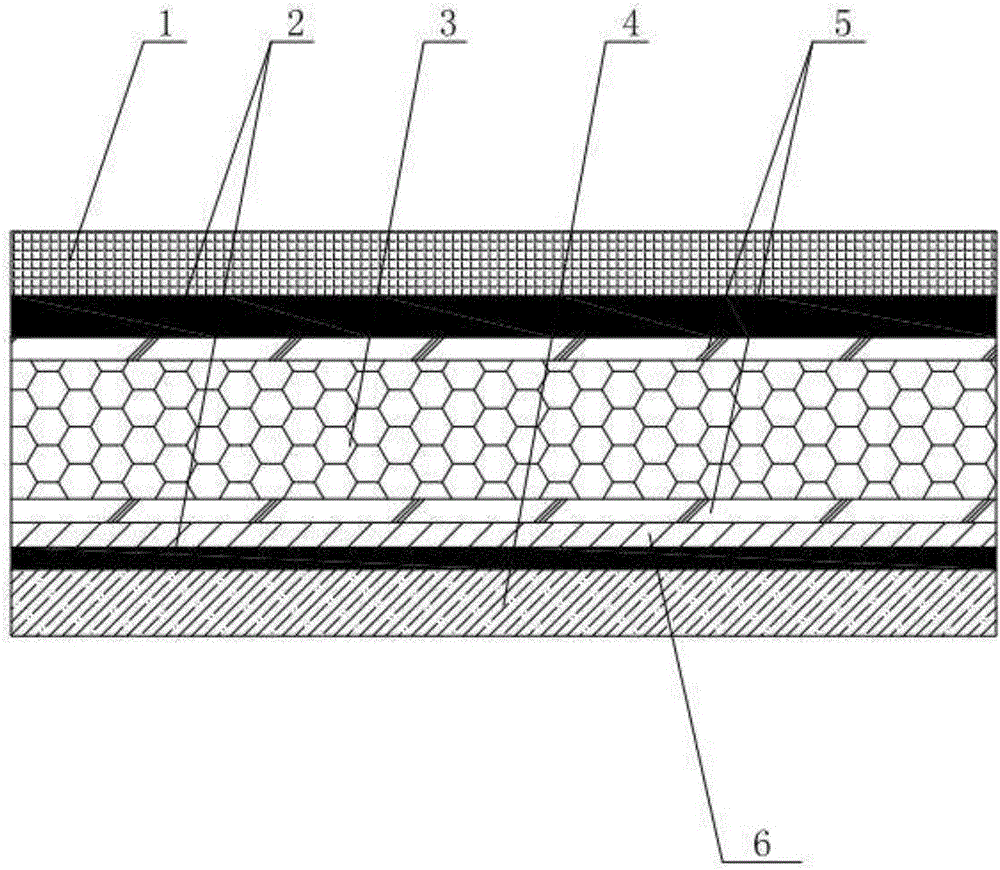

[0015] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0016] A solar backsheet with high barrier properties includes a polyester film 3, on one side of the polyester film 3, the weather-resistant layer 1 is bonded sequentially through a high reflection layer 5 and an adhesive layer 2, and the other side of the polyester film 3 is sequentially The weather-resistant adhesive layer 4 is bonded by the high reflection layer 5, the barrier layer 6, and the adhesive layer 2; the barrier layer 6 includes an oxygen barrier layer and a water vapor barrier layer, the thickness of the oxygen barrier layer is 10 to 110 microns, and the thickness of the water vapor barrier layer is 5-160 nanometers, the oxygen barrier layer is made of gelatin material, and the water vapor barrier layer is made of inorganic materials.

[0017] The thickness of the polyester film 3 is 80-400 microns. The thickness of the ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com