Binary composite La2O3 and Ta2O5-doped molybdenum negative electrode material and preparation method thereof

A cathode material and binary composite technology, applied in the direction of the cathode and magnetron of the time-of-flight electron tube, can solve the problems of sudden decrease in cathode emission current, poor cathode emission stability, and poor emission stability, so as to reduce evaporation, Chance reduction, launch performance boost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

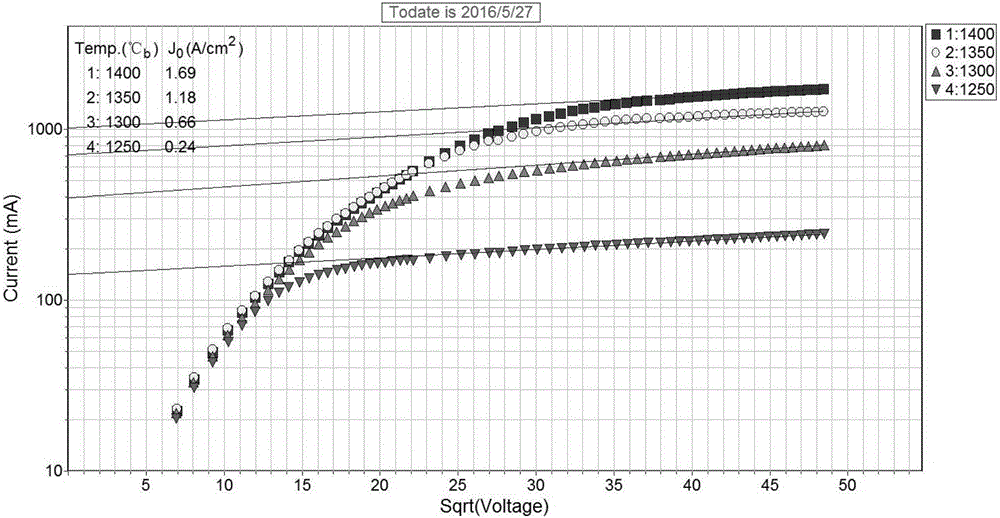

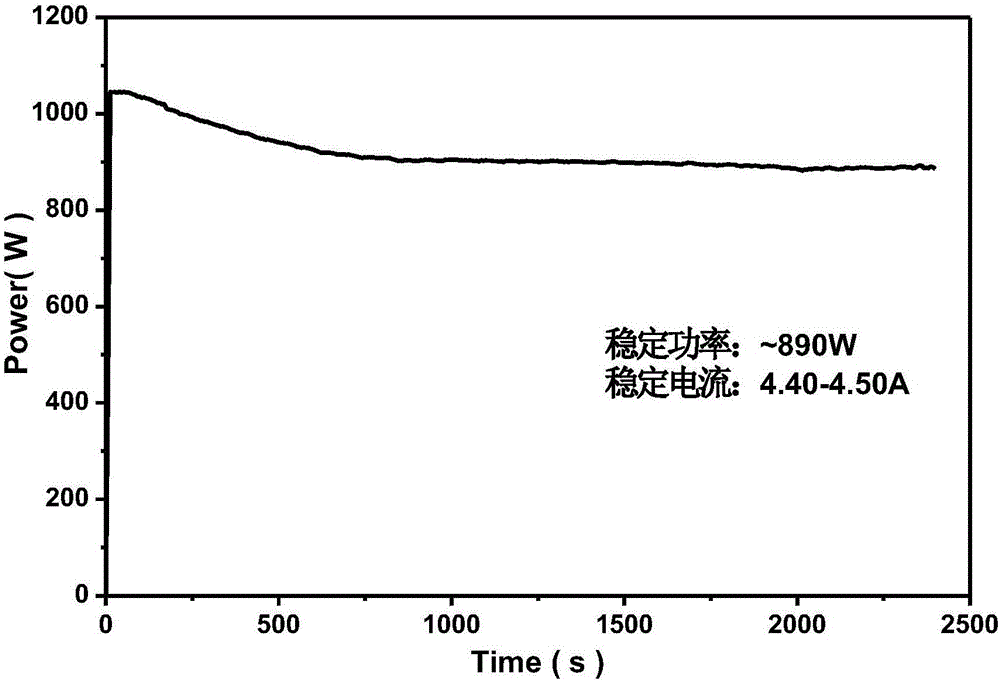

[0026]Example 1 Prepare a cathode in which the total amount of active material added is 3 wt%, and the rest is molybdenum. Mix 17.850g of ammonium heptamolybdate tetrahydrate solution, 0.784g of lanthanum nitrate solution, 0.005g of tantalum oxide powder and 21.242g of citric acid solution, stir in a water bath to obtain a wet gel, dry and decompose at 550°C. The decomposed powder is reduced in a hydrogen atmosphere. The reduction process is that the primary reduction temperature is 550°C, and the secondary reduction temperature is 850°C to obtain La 2 o 3 、 Ta 2 o 5 Molybdenum powder is doped; the obtained powder is subjected to compression molding at a pressure of 150 MPa, and the pressure is maintained for 15 minutes. The green body is sintered at a temperature of 1850°C and kept for 3 hours. finally got The cathode body is subjected to benzene vapor carbonization treatment on the cathode body, the carbonization temperature is 1450°C, and the temperature is kept for 1...

Embodiment 2

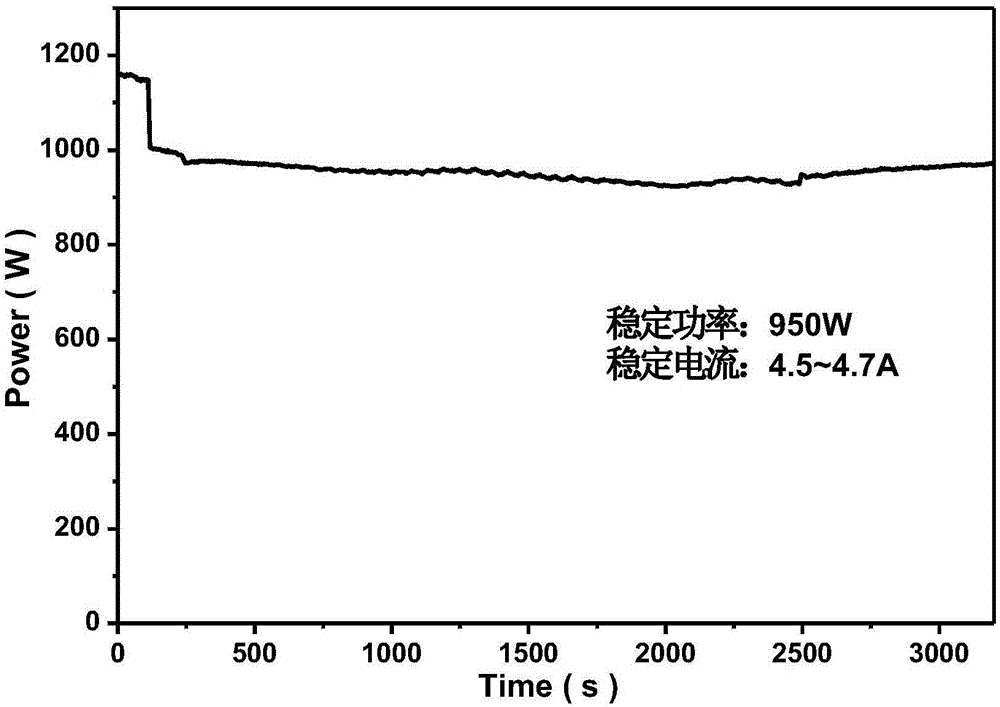

[0027] Example 2 Prepare a cathode in which the total amount of active material added is 3.5 wt%, and the rest is molybdenum. Mix 17.758g of ammonium heptamolybdate tetrahydrate solution, 0.917g of lanthanum nitrate solution, 0.005g of tantalum oxide powder and 21.132g of citric acid solution, stir in a water bath to obtain a wet gel, dry and decompose at 550°C. The decomposed powder is reduced in a hydrogen atmosphere. The reduction process is that the primary reduction temperature is 580°C, and the secondary reduction temperature is 890°C to obtain La 2 o 3 、 Ta 2 o 5 Doped molybdenum powder. The obtained powder was subjected to compression molding with a pressure of 150 MPa and a holding pressure of 15 minutes. The green body is sintered at a temperature of 1900°C and kept for 3 hours. finally got The cathode body is subjected to benzene steam carbonization treatment on the cathode body, the carbonization temperature is 1500°C, and the temperature is kept for 100s. ...

Embodiment 3

[0028] Example 3 Prepare a cathode in which the total amount of active material added is 4wt%, and the rest is molybdenum. Mix 17.666g of ammonium heptamolybdate tetrahydrate solution, 1.050g of lanthanum nitrate solution, 0.005g of tantalum oxide powder and 21.023g of citric acid solution, stir in a water bath to obtain a wet gel, dry and decompose at 550°C. The decomposed powder is reduced in a hydrogen atmosphere. The reduction process is that the primary reduction temperature is 600 °C, and the secondary reduction temperature is 900 °C to obtain La 2 o 3 、 Ta 2 o 5 Doped molybdenum powder. The obtained powder was subjected to compression molding with a pressure of 160 MPa and a hold pressure of 15 minutes. The green body is sintered at a temperature of 1950°C and kept for 2 hours. finally got The cathode body is subjected to benzene vapor carbonization treatment on the cathode body, the carbonization temperature is 1500°C, and the temperature is kept for 90s. Activ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com