Modified polylactic acid composite material and manufacturing method and application thereof

The technology of a composite material and a manufacturing method is applied in the field of modified polylactic acid composite material and its preparation, which can solve the problems of poor glass fiber reinforcement effect, high density, increased density of polylactic acid composite material, etc., so as to improve the tensile strength , The effect of improving mechanical properties and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-14 and comparative example 1-2

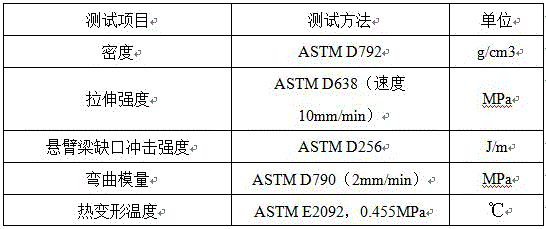

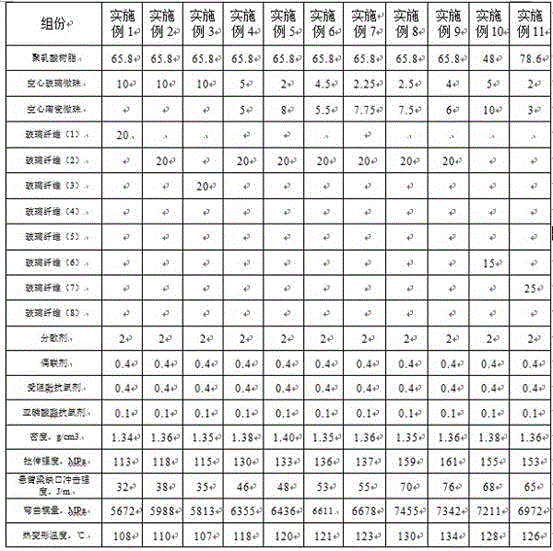

[0052] Examples 1-14 and Comparative Examples 1-2: Preparation of Modified Polylactic Acid Composite Materials

[0053] Each component is weighed according to the formula in Table 2, and it is produced by a melt blending extrusion process, and a single-screw extruder, a twin-screw extruder or a multi-screw extruder can be used, and the screw extruder has more than two Side feed port, the distance from side feed port to discharge port is not equal, control the processing temperature at 200°C~230°C, mix polylactic acid resin, dispersant, coupling agent and antioxidant in a high-speed mixer evenly , and then the mixed material is passed into the screw extruder from the main feed port, and the inorganic filler and glass fiber are mixed evenly and divided into more than two parts, which are respectively passed into the screw extruder from more than two side feed ports Middle; after melt blending, cooling, air-drying and granulation, the modified polylactic acid composite material w...

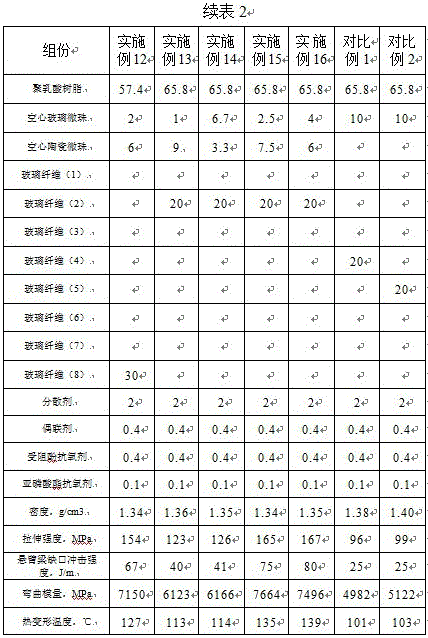

Embodiment 15-16

[0054] Embodiment 15-16: Preparation of modified polylactic acid composite material

[0055] The screw speed of the screw extruder is 300~500 rev / min, and there are two side feeding ports, the distance from one to the discharge port is 1 / 5~3 / 5 of the length of the screw extruder, and the other to The distance of the discharge port is 3 / 5~4 / 5 of the length of the screw extruder. All the other preparation methods are the same as in Examples 1-14.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com