Silicon-based ultraviolet photoelectric detector based on graphene and fabrication method of silicon-based ultraviolet photoelectric detector

A technology of electrical detectors and ultraviolet light, which is applied in the field of sensing, can solve the problems of blocking ultraviolet light and low optical response of photoelectric sensors, and achieve the effects of increasing ultraviolet response, reducing recombination, and improving response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

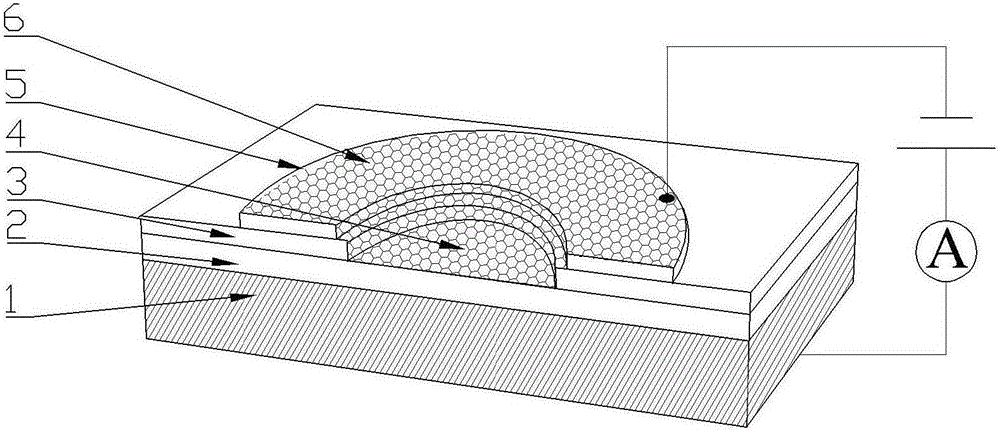

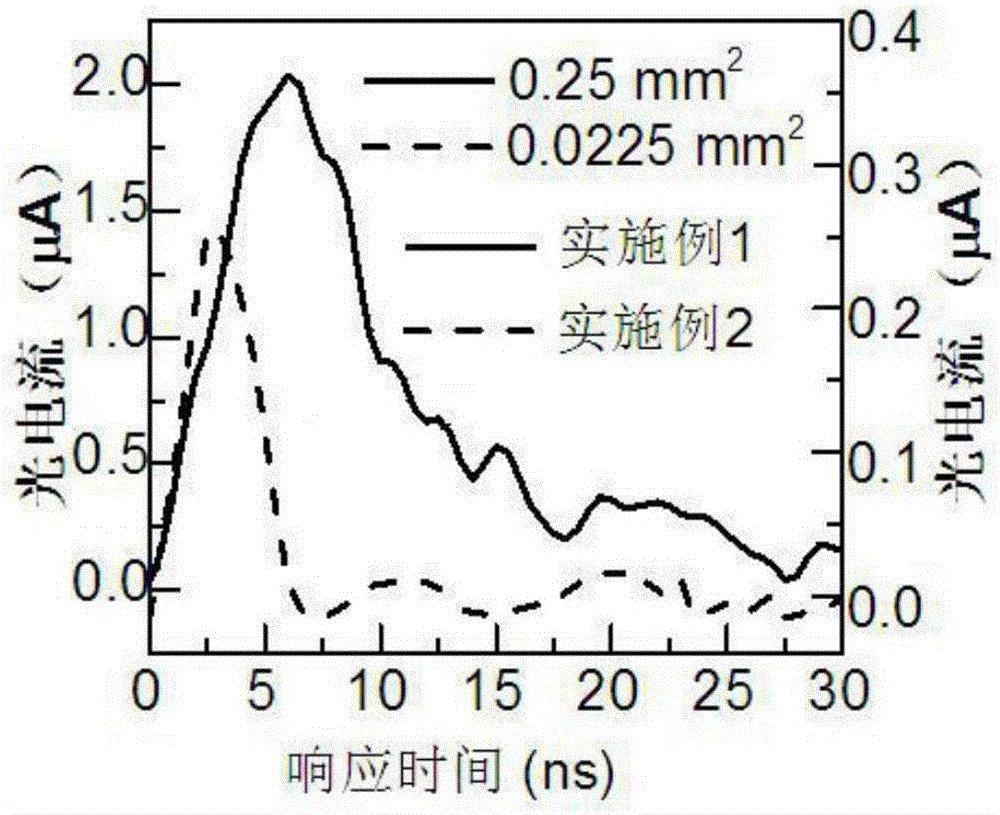

[0035] Depend on figure 1 As shown, a graphene-based silicon-based ultraviolet photodetector of this embodiment includes an epitaxial silicon wafer substrate, and the epitaxial silicon wafer substrate includes an N-type doped heavily doped layer 1 located in the lower layer and an upper layer N-type doped lightly doped layer 2, the doping concentration of heavily doped layer 1 is greater than 4.5×10 18 cm -3 , the thickness of the heavily doped layer 1 is 180-500 μm, and the doping concentration of the lightly doped layer 2 is 1×10 16 ~1×10 14 cm -3 , the thickness of the lightly doped layer 2 is 10-2000nm; the upper surface of the lightly doped layer 2 is provided with a silicon dioxide isolation layer 3 with a thickness of 300nm, and the center of the silicon dioxide isolation layer 3 is provided with a circular silicon dioxide layer with a photosensitive area. Window 4, photosensitive area is 0.25mm 2 The upper surface of the silicon dioxide isolation layer 3 is also p...

Embodiment 2

[0043] Depend on figure 1 As shown, a graphene-based silicon-based ultraviolet photodetector of this embodiment includes an epitaxial silicon wafer substrate, and the epitaxial silicon wafer substrate includes a P-type doped heavily doped layer 1 located in the lower layer and an upper layer P-type doped lightly doped layer 2, the doping concentration of heavily doped layer 1 is greater than 8×10 18 cm -3 , the thickness of the heavily doped layer 1 is 250-400 μm, and the doping concentration of the lightly doped layer 2 is 3×10 14 ~5×10 15 cm -3 , the thickness of the lightly doped layer 2 is 20-500nm; the upper surface of the lightly doped layer 2 is provided with a silicon dioxide isolation layer 3 with a thickness of 300nm, and the center of the silicon dioxide isolation layer 3 is provided with a circular silicon Window 4, photosensitive area is 0.0225mm 2 The upper surface of the silicon dioxide isolation layer 3 is also provided with a chromium / gold metal film top ...

Embodiment 3

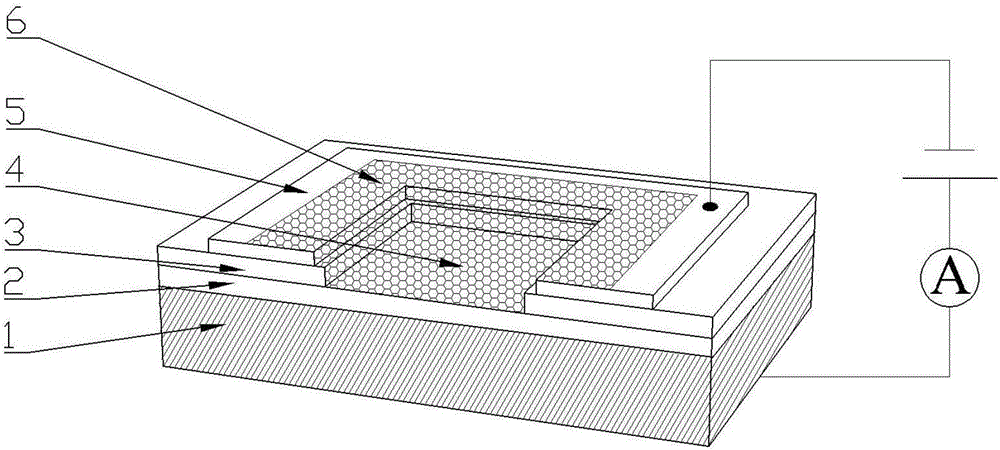

[0052] Such as image 3 As shown, a graphene-based silicon-based ultraviolet photodetector (array type) of the present embodiment includes an epitaxial silicon wafer substrate, and the epitaxial silicon wafer substrate includes an N-type doped heavily doped layer 1 located at the lower layer and the N-type doped lightly doped layer 2 located on the upper layer, and the doping concentration of the heavily doped layer 1 is greater than 8×10 18 cm -3 , the thickness of the heavily doped layer 1 is 250-400 μm, and the doping concentration of the lightly doped layer 2 is 3×10 14 ~5×10 15 cm -3 , the thickness of the lightly doped layer 2 is 20-500nm; the upper surface of the lightly doped layer 2 is provided with a silicon dioxide isolation layer 3 with a thickness of 300nm, and a rectangular silicon window with a photosensitive area is opened in the center of the silicon dioxide isolation layer 3 4. The upper surface of the silicon dioxide isolation layer 3 is also provided wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com