Epitaxial structure of semiconductor ultraviolet detector chip, preparation method of epitaxial structure and semiconductor ultraviolet detector chip

A technology of ultraviolet detector and epitaxial structure, which is applied in the field of ultraviolet detector, can solve the problems of large dark current and low spectral responsivity, and achieve the effect of reducing dark current, reducing dislocation density and improving ultraviolet responsivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

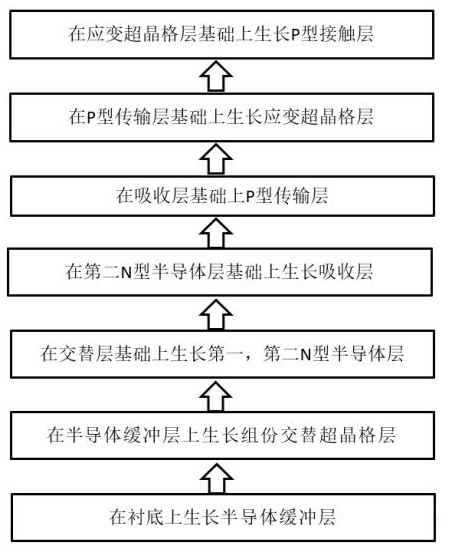

[0081] according to figure 1 The process shown in the present invention also provides a method for preparing the epitaxial structure described in the above technical solution, including the following steps:

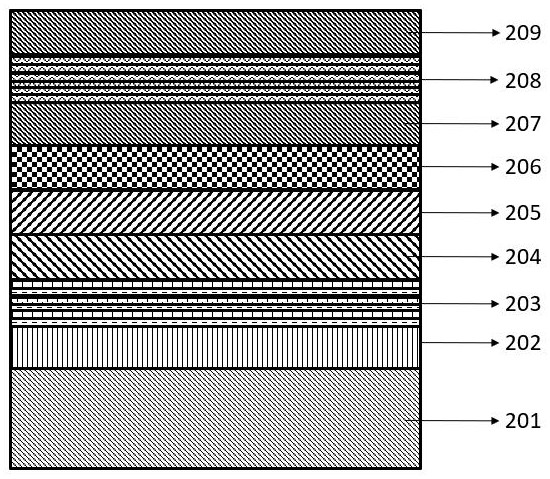

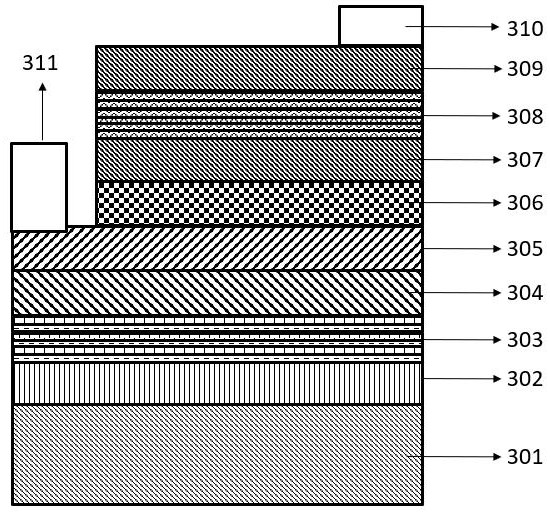

[0082] growing a semiconductor buffer layer, alternately grown superlattice layers, a first N-type semiconductor layer, a second N-type semiconductor layer, an ultraviolet light absorbing layer, a strained superlattice layer and a P-type contact layer in sequence on the upper surface of the substrate, The epitaxial structure is obtained.

[0083] Before the epitaxial structure is grown on the upper surface of the substrate, the substrate is preferably pretreated, and the pretreatment includes sequential baking and cleaning; in the present invention, the baking is preferably performed after the The substrate is placed in a reactor and baked at 1100°C in a hydrogen atmosphere. The present invention does not have any special restrictions on the cleaning process. It is carri...

Embodiment 1

[0103] Put the sapphire substrate into the MOCVD equipment, pass through hydrogen, and after baking at 1100°C, clean the oxides and impurities on the surface of the sapphire substrate;

[0104] AlN layers (thickness 1.5 μm) were grown sequentially on the surface of the cleaned sapphire substrate, and AlN layers (thickness 1 nm) and Al 0.85 Ga 0.15 N layer (thickness 2nm) 50 cycles, grow N-type doped Al 0.65 Ga 0.35 N layer (thickness 1μm, N-type doping concentration 5×10 18 cm -3 ), growing N-type doped Al 0.5 Ga 0.5 N layer (thickness 1 μm, doping concentration 1×10 19 cm -3 ), growing non-doped Al 0.4 Ga 0.6 N layer (thickness 150nm), growth of P-type doped Al 0.4 Ga 0.6 N transport layer (thickness 100nm, P-type doping concentration 1×10 19 cm -3 ), growing P-type doped Al 0.4 Ga 0.6 N contact layer (thickness 10nm, doping concentration 1×10 19 cm -3 ), growing P-type doped Al 0.01 Ga 0.99 N contact layer (thickness 100nm, doping concentration 2×10 19 cm...

Embodiment 2

[0112] Put the sapphire substrate into the MOCVD equipment, pass through hydrogen, and after baking at 1100°C, clean the oxides and impurities on the surface of the sapphire substrate;

[0113] AlN layers (thickness 1.5 μm) were grown sequentially on the surface of the cleaned sapphire substrate, and AlN layers (thickness 1 nm) and Al 0.85 Ga 0.15 N layer (thickness 2nm) 50 cycles, grow N-type doped Al 0.75 Ga 0.25 N layer (thickness 1μm, N-type doping concentration 5×10 18 cm -3 ), growing N-type doped Al 0.55 Ga 0.45 N layer (thickness 1 μm, doping concentration 1×10 19 cm -3 ), growing non-doped Al 0.4 Ga 0.6 N layer (thickness 150nm), growth of P-type doped Al 0.4 Ga 0.6 N transport layer (thickness 1.5nm, P-type doping concentration 1×1019 cm -3 ), growing P-type doped Al 0.25 Ga 0.75 N contact layer (thickness 1.0nm, doping concentration 1×10 19 cm -3 ), repeatedly growing the above-mentioned P-type doped Al 0.4 Ga 0.6 N transport layer and P type doped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com