Nanometer rare earth catalyzed ozonation method for normal temperature digestion of volatile organic matters

A volatile organic compound and nano rare earth technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., can solve the problems of poor structural stability, limited application range, high energy consumption, and achieve low cost, The equipment and operation are safe and simple, and the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

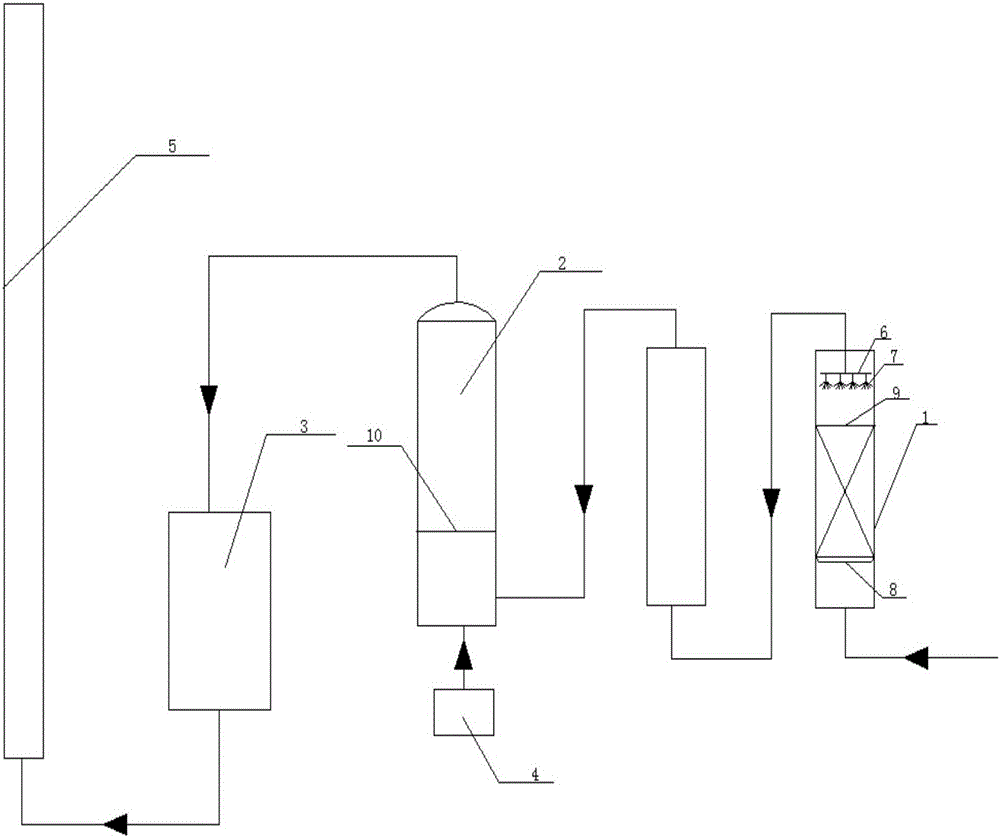

Image

Examples

Embodiment 1

[0042] (1) prepare target catalyst, specific process is as follows:

[0043] (a) Use the activated spherical nano-attapulgite as the catalyst carrier, impregnate the catalyst carrier in the nitrate solution adding nano-scale cerium, then dry and roast, cover the nano-rare earth oxide additive on the surface of the catalyst carrier, and the drying temperature is 100 ℃, the calcination temperature is 550℃ and lasts for 0.5h;

[0044] (b) The catalyst carrier whose surface has been covered with nano-rare earth oxide promoter is added by MnCl 3 solution and CuCl 2 The mixed halogen salt solution that solution is mixed into is stirred to make it mix evenly, and the mol ratio of the manganese ion and the copper ion in the described mixed halogen salt solution is 2:1;

[0045] (c) Then add sodium hydroxide solution to the mixed halogen salt solution of transition metals, adjust the pH value of the solution to 7, let stand at room temperature for 6 hours, filter and wash until the w...

Embodiment 2

[0054] (1) prepare target catalyst, specific process is as follows:

[0055] (a) Use the activated spherical nano-attapulgite as the catalyst carrier, impregnate the catalyst carrier in the nitrate solution adding nano-scale lanthanum, then dry and roast, and cover the nano-rare earth oxide auxiliary agent on the surface of the catalyst carrier, the drying temperature is 200 ℃, the calcination temperature is 350℃ and lasts for 2h;

[0056] (b) The catalyst carrier whose surface has been covered with nano-rare earth oxide promoter is added by CrCl 3 solution and CuCl 2 The mixed halogen salt solution that solution is mixed into is stirred to make it mix evenly, and the mol ratio of the chromium ion and the copper ion in the described mixed halogen salt solution is 2:1;

[0057] (c) Then add sodium hydroxide solution to the transition metal mixed halogen salt solution, adjust the pH value of the solution to 7, let stand at room temperature for 8 hours, filter and wash until th...

Embodiment 3

[0068] (1) prepare target catalyst, specific process is as follows:

[0069] (a) Use the activated spherical nano-attapulgite as the catalyst carrier, impregnate the catalyst carrier in the nitrate solution adding nano-scale erbium, then dry and roast, cover the surface of the catalyst carrier with nano-rare earth oxide additives, and the drying temperature is 150 °C , the calcination temperature is 350°C and lasts for 2h;

[0070] (b) The catalyst carrier whose surface has been covered with nano-rare earth oxide promoter is added by MnCl 3 solution and CrCl 2 The mixed halogen salt solution that solution is mixed into is stirred to make it mix evenly, and the mol ratio of the manganese ion and the chromium ion in the described mixed halogen salt solution is 2:1;

[0071] (c) Then add sodium hydroxide solution to the mixed halogen salt solution of transition metals, adjust the pH value of the solution to 7, let stand at room temperature for 8 hours, filter and wash until the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com