Corrosion-resistance weldable titanium alloy with high strength and high impact toughness and preparation method thereof

A titanium alloy, high-impact technology, applied in the field of titanium alloys, can solve the problems of low impact toughness and poor performance, and achieve the effects of good strength and plastic toughness, good cold and hot processing performance, good welding performance and seawater corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

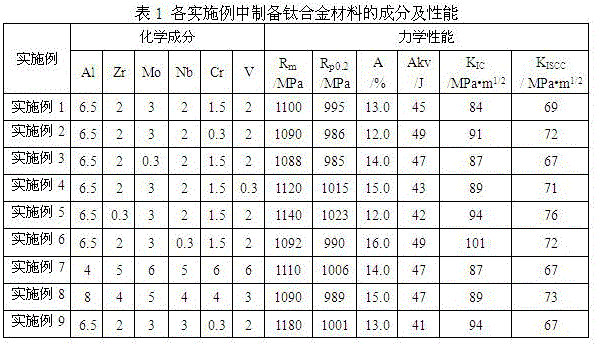

[0020] Embodiment 1: Ti-6.5Al-3Mo -2V -2Zr-2Nb -1.5Cr alloy

[0021] Weigh the raw materials according to the ingredients listed in Example 1, 6.5wt.% of the aluminum element, 2wt.% of the zirconium element, 1.5wt.% of the chromium element, 3wt.% of the molybdenum element, 2wt.% of the niobium element, 2wt.% .% vanadium element and industrial grade 1 sponge titanium are smelted into alloy ingots three times through mixing materials, pressing electrode rods, and vacuum consumable electric arc furnace. via T β +150°C blanking, α+β phase zone forging into forgings, rolling into wide sheets with different thicknesses by hot and cold rolling mills. After being treated by a suitable heat treatment system, the properties of the alloy material are shown in Table 1.

Embodiment 2

[0022] Example 2: Ti-6.5Al-3Mo -2V -2Zr-2Nb -0.3Cr alloy

[0023] Weigh the raw materials according to the ingredients listed in Example 2, with 6.5wt.% aluminum element, 2wt.% zirconium element, 0.3wt.% chromium element, 3wt.% molybdenum element, 2wt.% niobium element, 2wt.% .% vanadium element and industrial grade 1 sponge titanium are smelted into alloy ingots three times through mixing materials, pressing electrode rods, and vacuum consumable electric arc furnace. via T β +150°C blanking, α+β phase zone forging into forgings, rolling into wide sheets with different thicknesses by hot and cold rolling mills. After being treated by a suitable heat treatment system, the properties of the alloy material are shown in Table 1.

Embodiment 3

[0024] Example 3: Ti-6.5Al-0.3Mo -2V -2Zr-2Nb -1.5Cr alloy

[0025] Weigh the raw materials according to the ingredients listed in Example 3, 6.5wt.% of the aluminum element, 2wt.% of the zirconium element, 1.5wt.% of the chromium element, 0.3wt.% of the molybdenum element, 2wt.% of the niobium element, 2wt.% vanadium element and industrial grade 1 sponge titanium were smelted into alloy ingots three times through mixing, pressing electrode rods, and vacuum consumable electric arc furnace. via T β +150°C blanking, α+β phase zone forging into forgings, rolling into wide sheets with different thicknesses by hot and cold rolling mills. After being treated by a suitable heat treatment system, the properties of the alloy material are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com