Engineering bacteria with deletion of organic acid production pathway and its application in co-production of 1,3-propanediol, 2,3-butanediol and ethanol

A technology of organic acids and engineered bacteria, applied in the directions of bacteria, microorganism-based methods, biochemical equipment and methods, etc., can solve the problem of no co-production of chemicals, and achieve the effect of reducing yield, reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

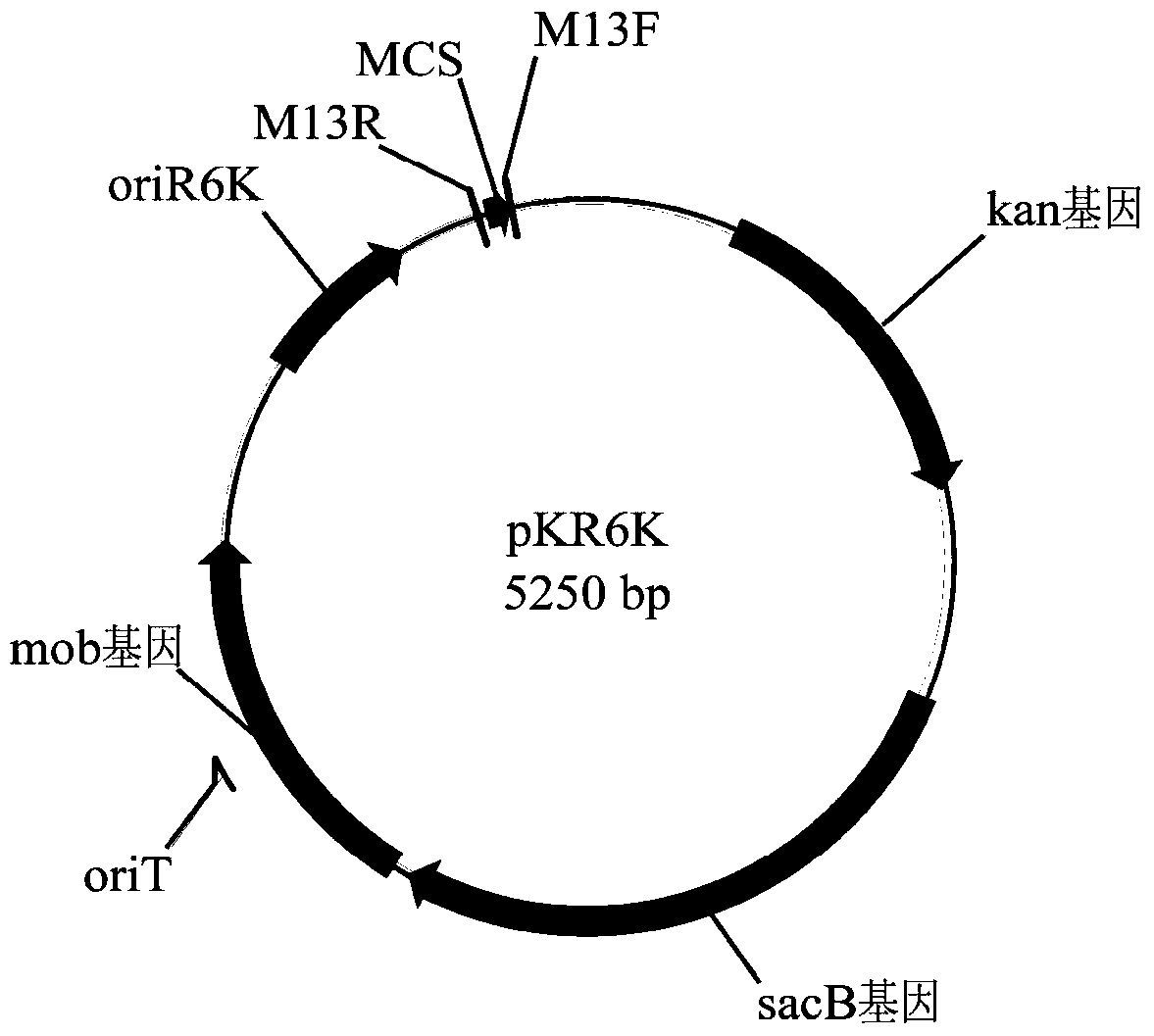

[0036] Example 1: Knockout of lactate dehydrogenase gene ldhA in Klebsiella

[0037] (1) Cloning of the homologous sequences of the upstream and downstream parts of the lactate dehydrogenase gene ldhA

[0038] Primers were designed according to the genome sequence of Klebsiella ATCC 25955, and the upstream and downstream partial homologous sequences of lactate dehydrogenase gene ldhA were PCRed. Using the genomic DNA of Klebsiella ATCC 25955 as a template, primers composed of primers ldhA-1: ATCGGAATTCAGGGTATTGAGCTGGGCGTC and primers ldhA-2: ATTCAAGCTTCGAAACCTGTCCGAACGCCA were used for PCR amplification to obtain a partial homologous sequence upstream of ldhA; primers ldhA-3 : ATTAAAGCTTCCGTTGGCGGTTTTGGCAGT and primer ldhA-4: TCTACCCGGGTTTTTCAGCCGCTTTTCTCTCT primers were used for PCR amplification to obtain partial homologous sequences downstream of ldhA. The PCR amplification conditions are: 95°C for 5 minutes; 95°C for 30 seconds, 60°C for 30 seconds, 72°C for 1 minute, a t...

Embodiment 2

[0051] Example 2: Knockout of acetate kinase gene ackA in Klebsiella

[0052] (1) Cloning of the homologous sequences of the upstream and downstream parts of the acetate kinase gene ackA

[0053] According to the method of embodiment 1 step (1), design primer, take the genomic DNA of Klebsiella ATCC 25955 as template, carry out PCR amplification with the primer that primer ackA-1: ATCGGAATTCTAGCGGGTGGCACGAATAAT and primer ackA-2: ATTAGGATCCGCTACCGCAGTTCAGAACCA form The upstream sequence of ackA gene was obtained; the downstream sequence of ackA gene was obtained after PCR amplification with primers composed of primer ackA-3: GCAAGGATCCCTATACCATCGCACTGACCG and primer ackA-4: TCCCCCCGGGCGAGACAAAAGACTTTCATC. The PCR product is recovered and purified to obtain the target fragment.

[0054] (2) Suicide carrier build

[0055] Use restriction endonucleases EcoRI and BamHI to digest the homologous fragment upstream of the ackA gene, use BamHI and XmaI to digest the homologous frag...

Embodiment 3

[0058] Example 3: Knockout of pyruvate oxidase gene poxB in Klebsiella

[0059] (1) Cloning of the homologous sequences of the upstream and downstream parts of the pyruvate oxidase gene poxB

[0060] According to the method of embodiment 1 step (1), design primer, take the genomic DNA of Klebsiella ATCC 25955 as template, carry out PCR amplification with primer poxB-1:GCATGAATTCTTTCGCTGCCACTTTTATCCA and primer poxB-2:ATTAGGATCCGGCGAAAACCAACTGGCTCA The upstream sequence of poxB gene was obtained; the downstream sequence of poxB gene was obtained after PCR amplification with primers composed of primer poxB-3: ATGCGGATCCACGGTCTGCTTCATGATCTC and primer poxB-4: CGTACTGCAGATCTAAGCCGACCATCAGCC. The PCR product is recovered and purified to obtain the target fragment.

[0061] (2) Suicide carrier build

[0062] Use restriction endonucleases EcoRI and BamHI to digest the homologous fragment upstream of the poxB gene, use BamHI and PstI to digest the homologous fragment downstream of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com