A kind of high temperature resistant, thermally conductive nylon composite material and preparation method thereof

A nylon composite material and composite material technology are used in the field of high temperature resistant, thermally conductive nylon composite materials and their preparation, which can solve the problems of high brittleness, stress cracking, and high processing requirements, and achieve improved toughness, enhanced bridging ability, and improved mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

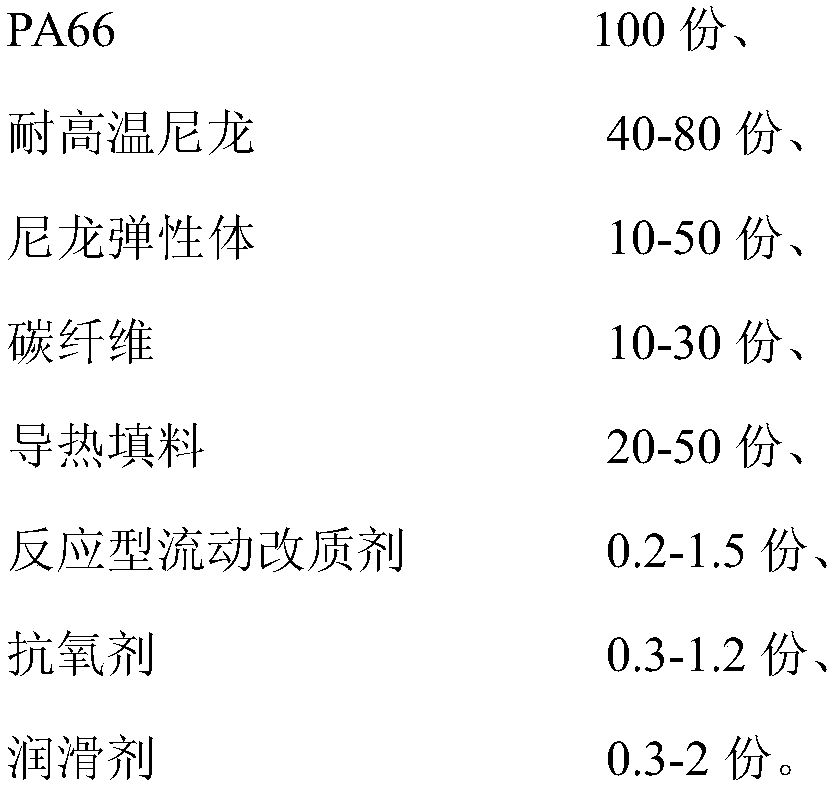

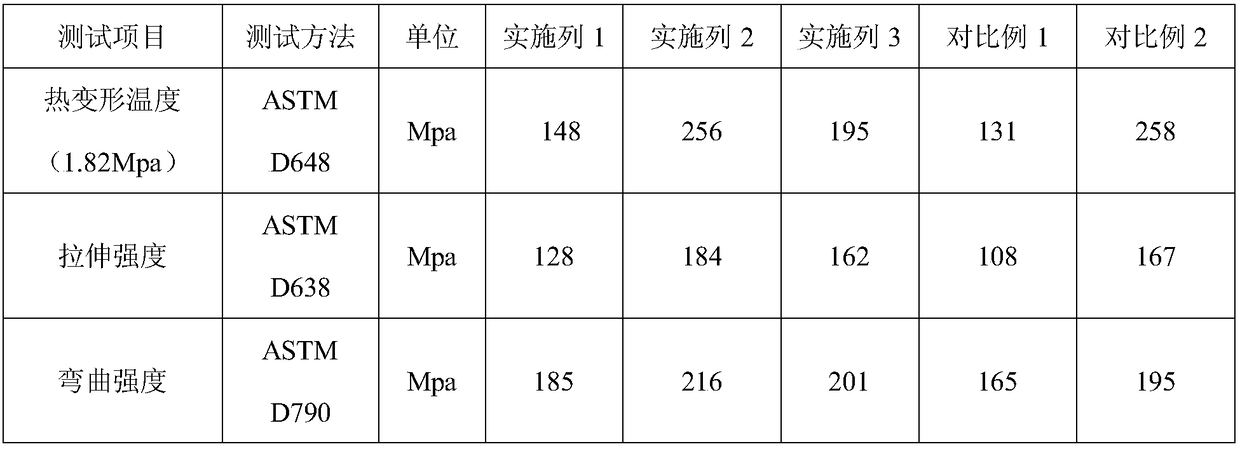

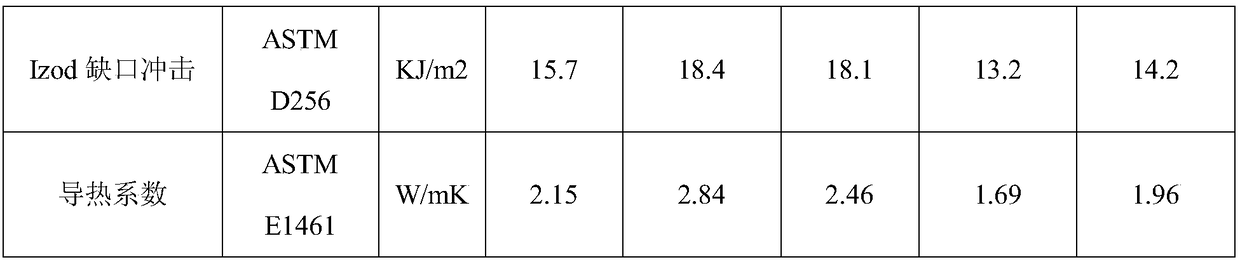

[0032] Example 1 Preparation of high temperature resistant and thermally conductive nylon composite material (1)

[0033] (1) Dry the nylon at 110°C for 4 hours.

[0034] (2) Weigh the raw materials: 100 parts of PA66, 40 parts of PA9T, 10 parts of PA1212 elastomer, 20 parts of alumina, 0.2 part of reactive flow modifier, 0.3 part of antioxidant and 0.3 part of lubricant, premixed uniformly; The PA66 is a homopolymer PA66 with a relative molecular weight of 15000-20000; the reactive flow modifier is Sanstab 2303; the antioxidant is a hindered phenol antioxidant; the lubricant is silicone powder.

[0035] (3) Add the mixture from the barrel of the first section of the twin-screw extruder, add 10 parts of carbon fiber from the glass fiber feed port, control the speed at 1100r / min, and the temperature at 260-270°C for extrusion granulation. The material is extruded and cut into pellets under cold water; the diameter of the carbon fiber is 7-20 μm.

[0036] (4) Dry the cut particles, inj...

Embodiment 2

[0037] Example 2 Preparation of high temperature resistant and thermally conductive nylon composite material (2)

[0038] (1) Dry the nylon at 110°C for 4 hours.

[0039] (2) Weigh 100 parts of PA66, 80 parts of PA12T, 50 parts of PA1212 elastomer, 50 parts of aluminum nitride, 1.5 parts of reactive flow modifier, 1.2 parts of antioxidants, and 2.0 parts of lubricants, and premix them evenly; the PA66 It is homopolymer PA66 with a relative molecular weight of 15000-20000; the reactive flow modifier is Sanstab 2303; the antioxidant is a phosphite antioxidant; and the lubricant is Montan wax.

[0040] (3) Add the mixture from the barrel of the first section of the twin-screw extruder, add 30 parts of carbon fiber from the glass fiber feed port, control the speed at 1100r / min, and the temperature at 260-270°C for extrusion granulation. The material is extruded and cut into pellets under cold water; the diameter of the carbon fiber is 7-20 μm.

[0041] (4) Dry the cut particles and injec...

Embodiment 3

[0042] Example 3 Preparation of high temperature resistant and thermally conductive nylon composite material (3)

[0043] (1) Dry the nylon at 110°C for 4 hours.

[0044] (2) Weigh 100 parts of PA66, 60 parts of PA10T, 30 parts of PA1212 elastomer, 30 parts of boron nitride, 1.0 part of reactive flow modifier, 0.8 part of antioxidant, and 1.2 part of lubricant, and premix it evenly; the PA66 It is homopolymer PA66 with a relative molecular weight of 15000-20000; the reactive flow modifier is Sanstab 2303; the antioxidant is a sulfur-containing antioxidant; and the lubricant is a polyester wax.

[0045] (3) Add the mixture from the barrel of the first section of the twin-screw extruder, add 20 parts of glass fiber from the barrel of the fourth section of the twin-screw extruder, control the speed at 1100r / min, and the temperature at 260-270°C for extrusion granulation , The material is extruded and cut into pellets under cold water; the diameter of the carbon fiber is 7-20 μm.

[0046...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com