A kind of in-situ self-generated aluminum-silicon gradient composite material and preparation method thereof

A composite material, in-situ self-generating technology, applied in the direction of semiconductor/solid-state device components, electric solid-state devices, semiconductor devices, etc. Processed molding, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

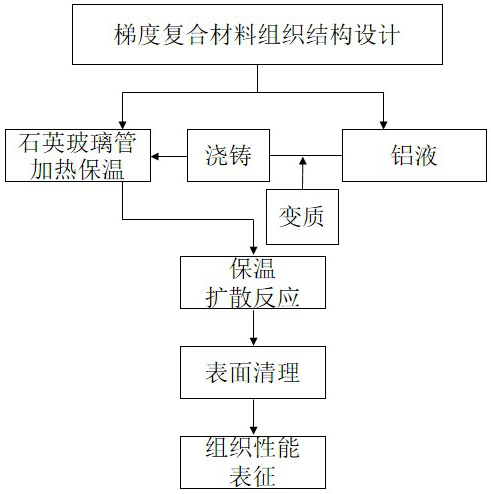

Method used

Image

Examples

Embodiment 1

[0038] (1) Place the high-purity silica quartz glass vessel with the same workpiece shape in a heating furnace and heat it to 800 o C preheating and heat preservation;

[0039] (2) will be 800 o C pure aluminum liquid is poured into step (1) in the high-purity silica quartz glass vessel, leaves standstill at 800 o C insulation;

[0040] (3) Control the holding time of step (2) for 2 hours to ensure that the aluminum liquid and silicon dioxide react, the silicon atoms diffuse into the aluminum liquid, and finally cool with the furnace;

[0041] (4) Removing the residual quartz glass on the surface of the material in step (3) to obtain an in-situ self-generated aluminum-silicon gradient composite material consistent with the shape of the quartz glass vessel.

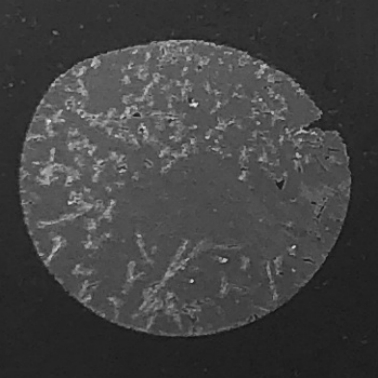

[0042] (5) Macro organization see figure 2 , massive primary silicon is distributed in the outer ring; the mosaic diagram of the microstructure from outside to inside image 3 , it can be clearly seen that the layere...

Embodiment 2

[0044] (1) Place the high-purity silica quartz glass vessel with the same workpiece shape in a heating furnace and heat it to 800 o C preheating and heat preservation;

[0045] (2) Melt high-purity aluminum in a high-purity aluminum oxide ceramic crucible, and add 3wt.% lanthanum to the aluminum liquid.

[0046] (3) Step (2) molten aluminum is heated to 800 o C is poured into step (1) in the high-purity silica quartz glass vessel, leaves standstill at 800 o C insulation;

[0047] (4) Control the holding time of step (3) for 2 hours to ensure that the aluminum liquid and silicon dioxide react, and the silicon atoms diffuse into the aluminum liquid, and finally cool with the furnace;

[0048] (5) Removing the residual quartz glass on the surface of the material in step (4) to obtain an in-situ self-generated aluminum-silicon gradient composite material consistent with the shape of the quartz glass vessel.

[0049] (6) See macro organization chart Figure 5 (The white spots ...

Embodiment 3

[0051] (1) Place the high-purity silica quartz glass vessel with the same workpiece shape in a heating furnace and heat it to 800 o C preheating and heat preservation;

[0052] (2) Melt high-purity aluminum in a high-purity aluminum oxide ceramic crucible, and add 1.00wt.% cerium to the aluminum liquid.

[0053] (3) Step (2) molten aluminum is heated to 800 o C is poured into step (1) in the high-purity silica quartz glass vessel, leaves standstill at 800 o C insulation;

[0054] (4) Control the holding time of step (3) for 2 hours to ensure that the aluminum liquid and silicon dioxide react, and the silicon atoms diffuse into the aluminum liquid, and finally cool with the furnace;

[0055] (5) Removing the residual quartz glass on the surface of the material in step (4) to obtain an in-situ self-generated aluminum-silicon gradient composite material consistent with the shape of the quartz glass vessel.

[0056] (6) See macro organization chart Figure 7 (The white spots ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com